Process for pattern transfer

A technology of pattern transfer and pattern light, which is applied in the direction of photographic process, optics, and optomechanical equipment on the pattern surface, can solve the problem of not being able to effectively solve the problem of missing, not applicable to semiconductor and related semiconductor manufacturing processes, and increasing the critical dimension of pattern formation And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

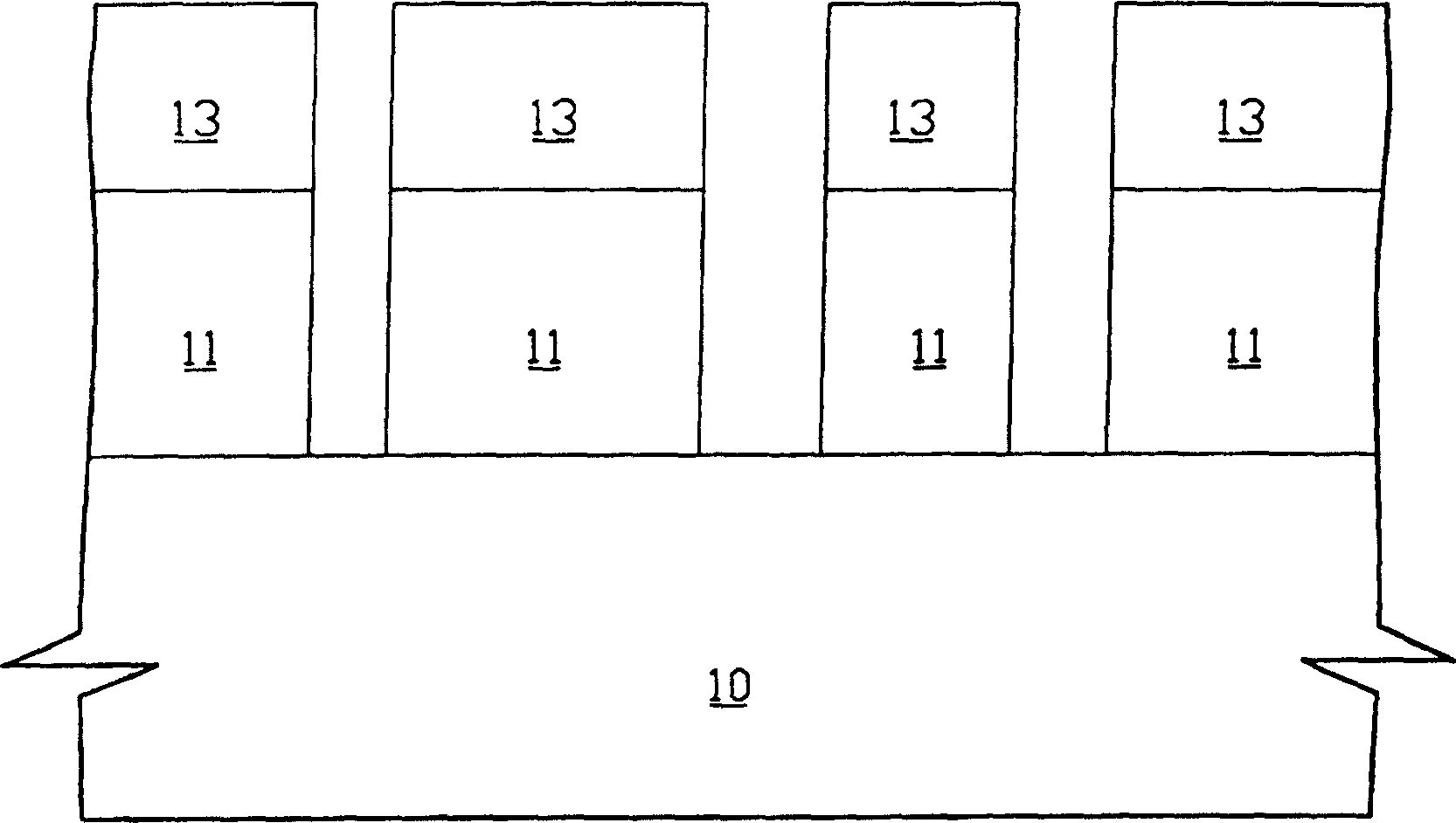

[0016] In view of the various defects encountered in the conventional technology when changing the photoresist material and increasing the thickness of the photoresist to increase the etching resistance of the photoresist, the present invention proposes the following entry points:

[0017] (1) As long as the etching resistance of a certain material is large enough, the damage caused by etching can be effectively prevented without increasing the thickness of the material.

[0018] (2) As long as there is a material with a large enough etching resistance on the surface of the photoresist, which can offset the effect of the etching process on the photoresist, the material of the photoresist can not be changed.

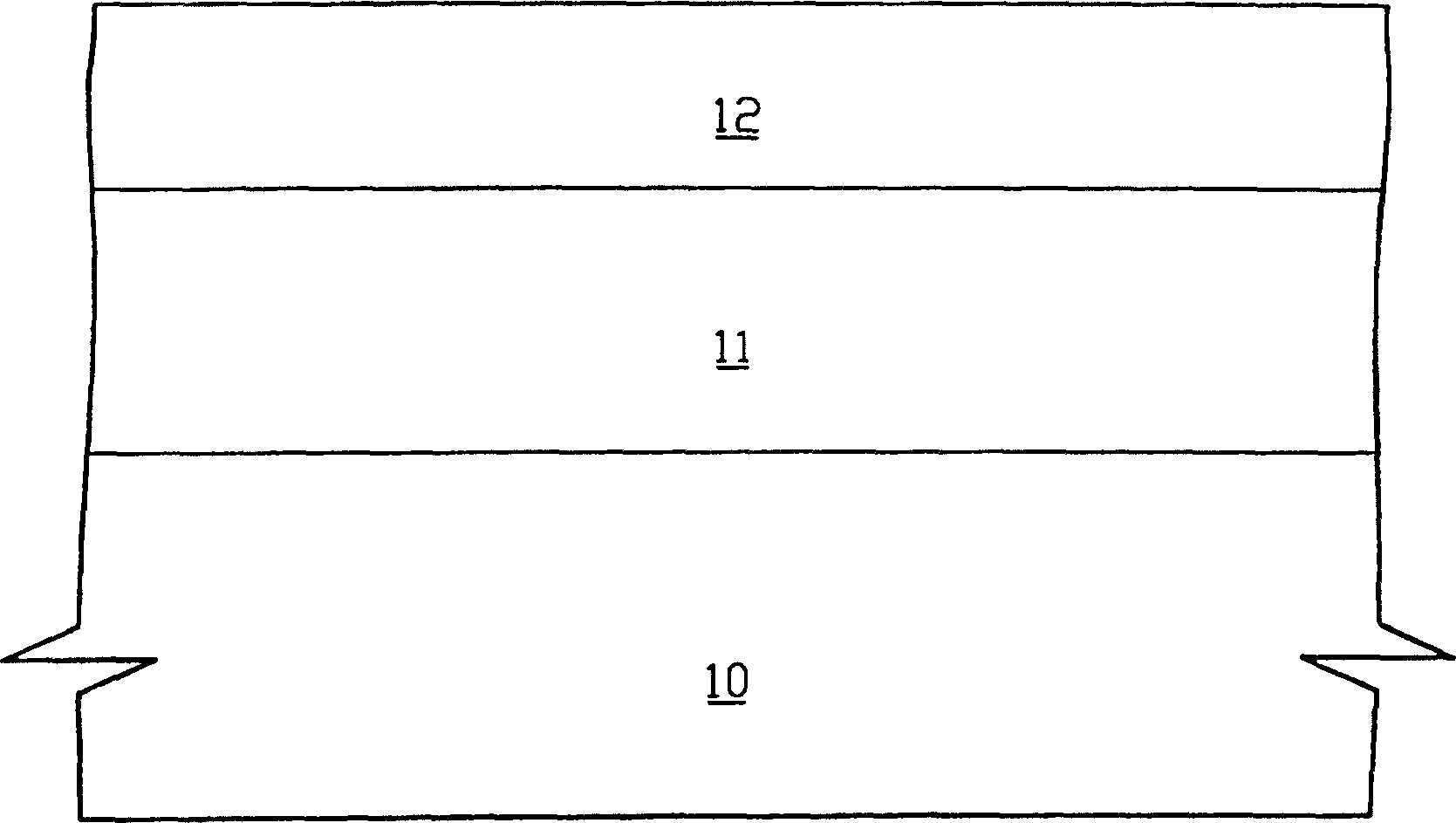

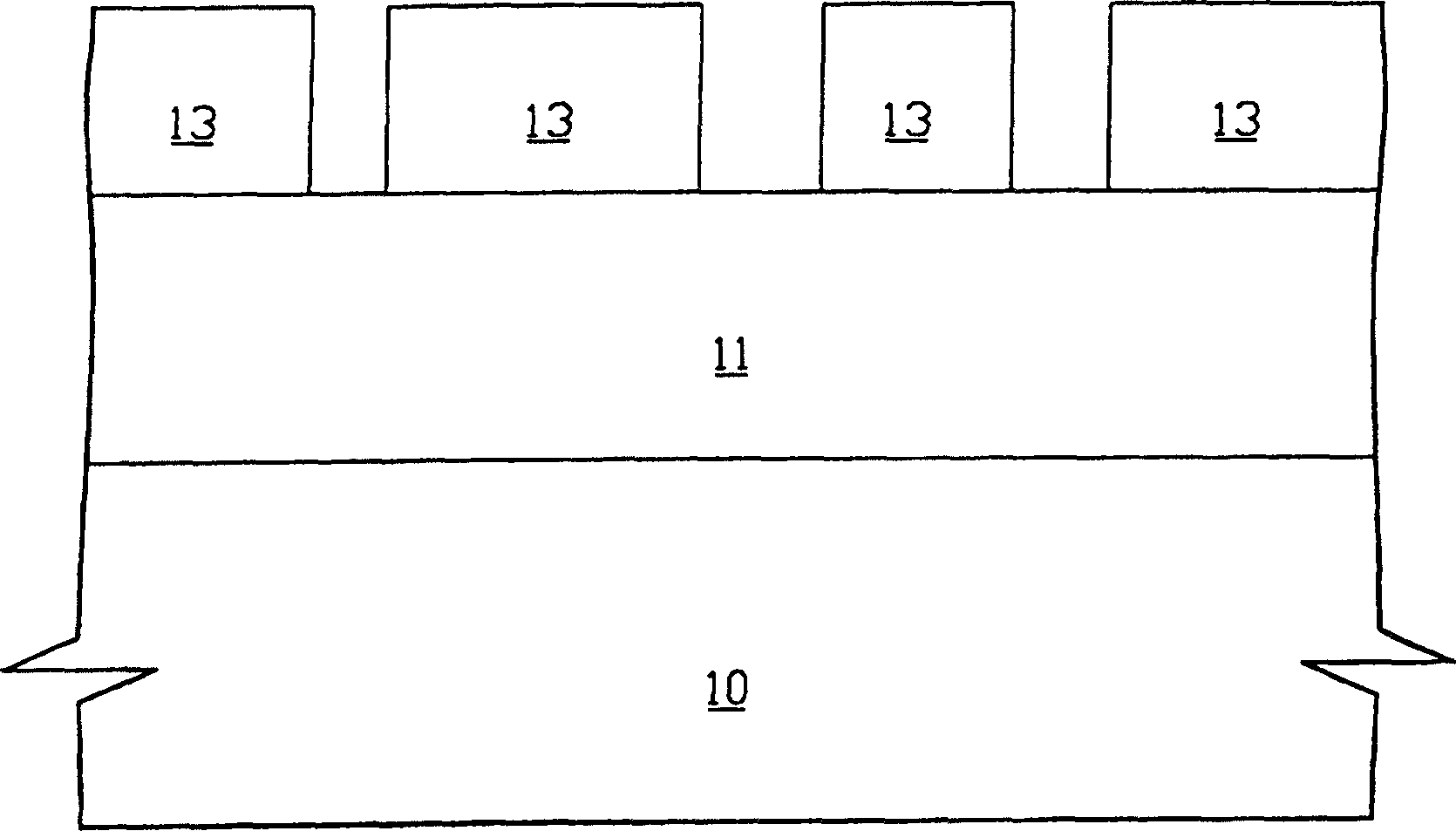

[0019] (3) Since the pattern transfer process is to transfer the pattern of the structure on the substrate to the substrate, it is possible to use photoresist and high etching resistance material to form a structure with a specific pattern instead of only using photoresist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com