Optical disc and optical disc drive

A technology of optical disc drive and optical disc, which is applied in the direction of instruments, light beam reproduction, optical record carrier, etc., and can solve the problems of increasing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

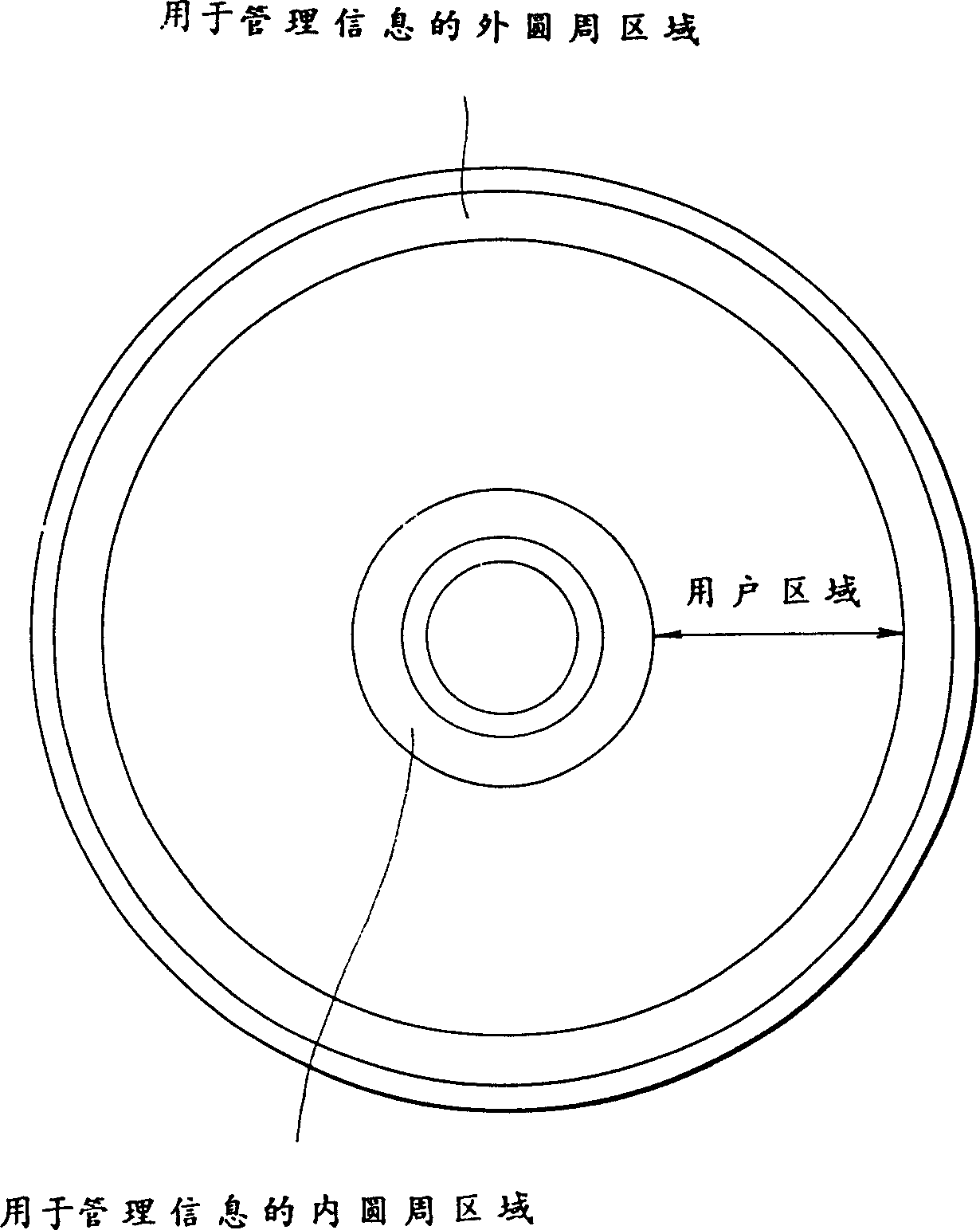

[0047] now refer to figure 2 , to illustrate the magneto-optical disk (hereinafter simply referred to as "disc D") of the present invention. As shown in the figure, the disc D has management information areas formed along the inner and outer peripheries, respectively, for a predetermined number of tracks, respectively. Each of such management information areas includes an area in which disc management information is recorded, a buffer area, a test area, and others. The disc D also forms a user area between the inner and outer circumference management information areas, and the user records data to or plays back data from the user area.

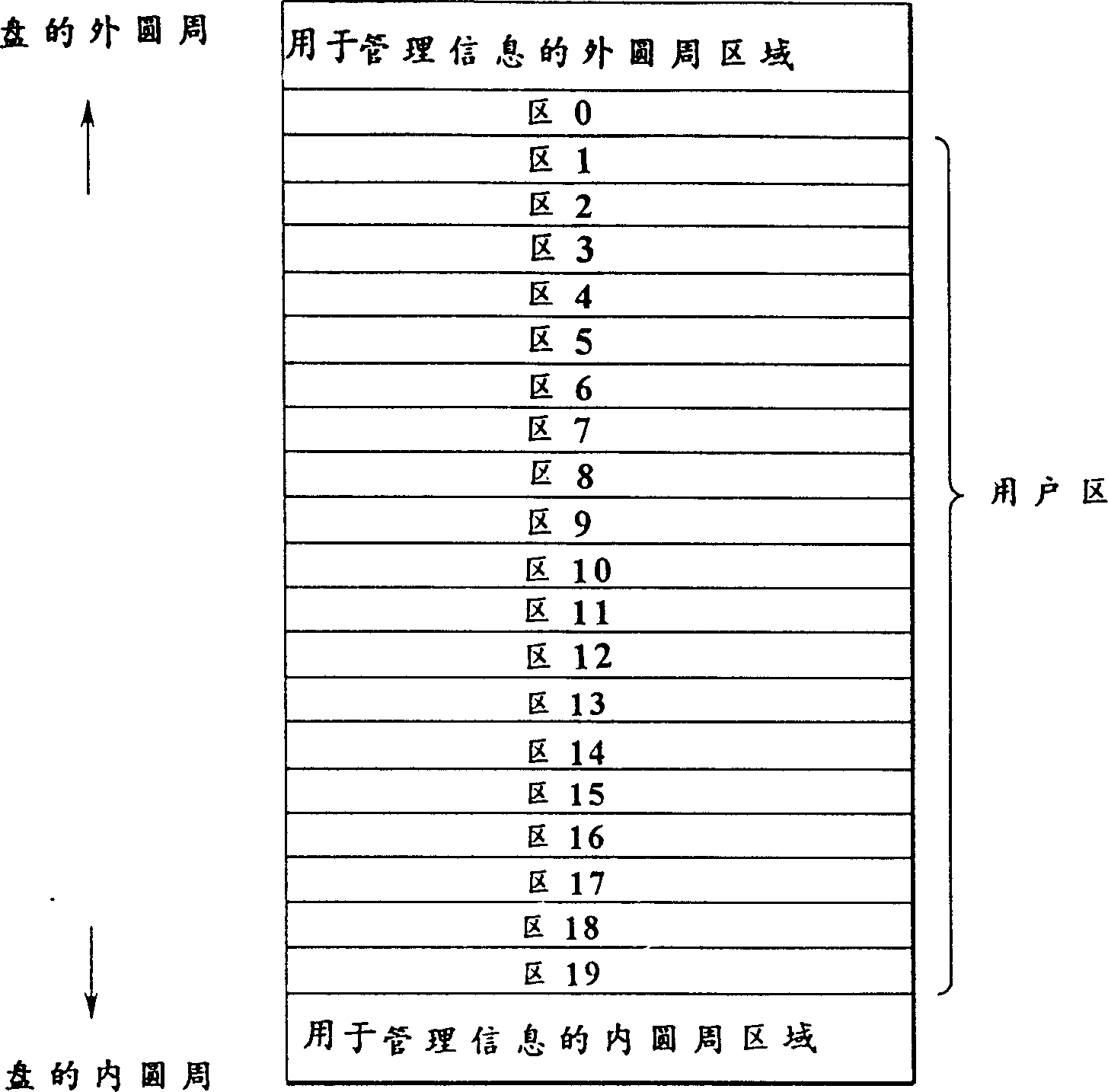

[0048] For example, if image 3 As shown, the user area is divided into 20 areas including 0 to 19. Data is to be recorded to or reproduced from such an optical disc D by the zone CAV or zone CLV method, for example.

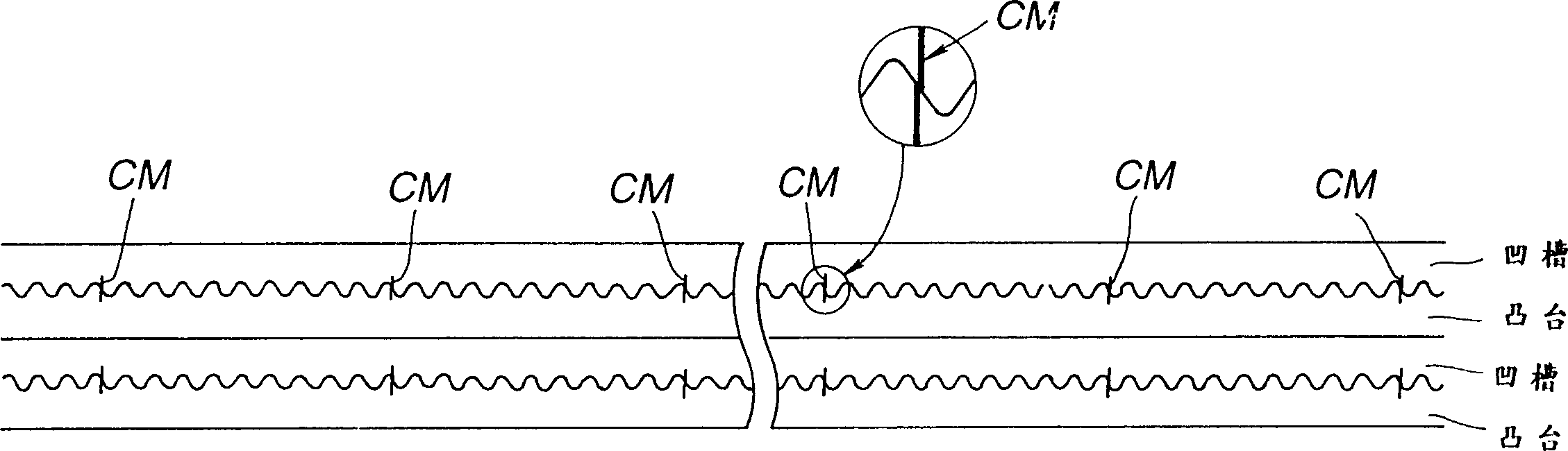

[0049] refer to Figure 4 and 5A to 5C, describe the structure of tracks, frames and segments.

[0050] Figure 4 Show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com