Method of screening laminated ceramic capacitor

A technology of ceramic capacitors and screening methods, applied in the direction of multilayer capacitors, capacitors, capacitor manufacturing, etc., can solve problems such as deterioration of insulation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

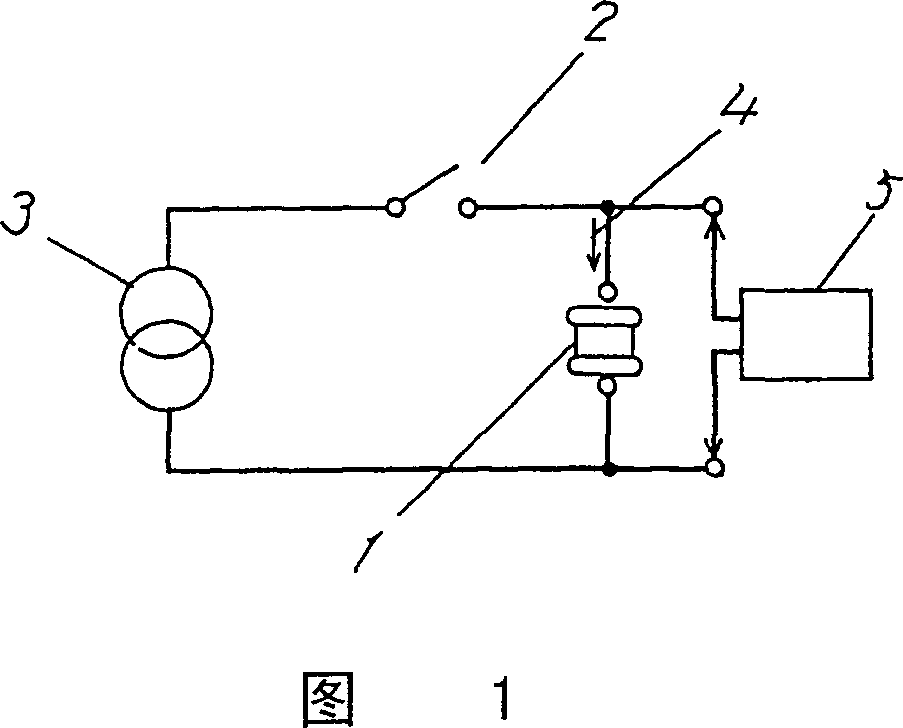

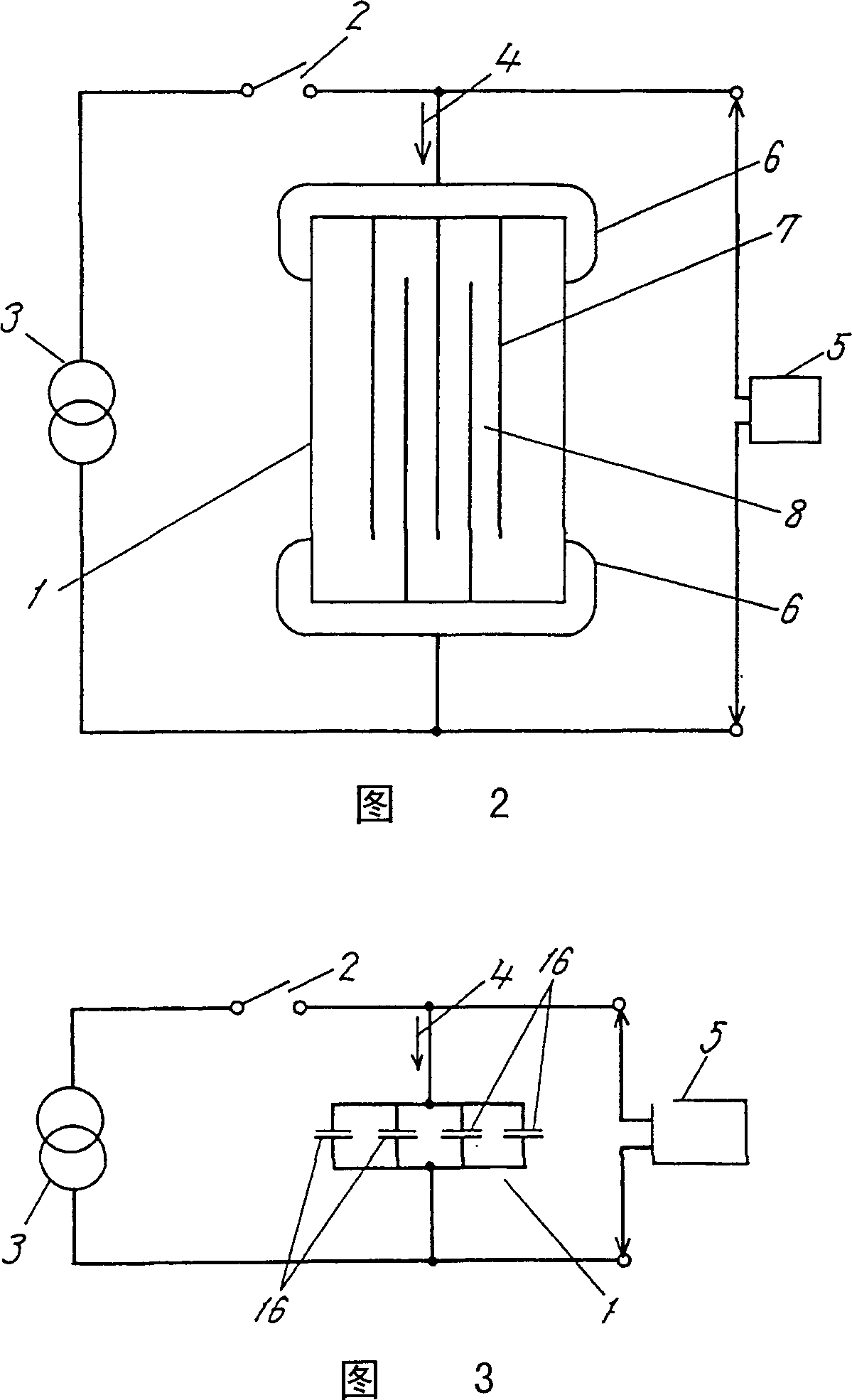

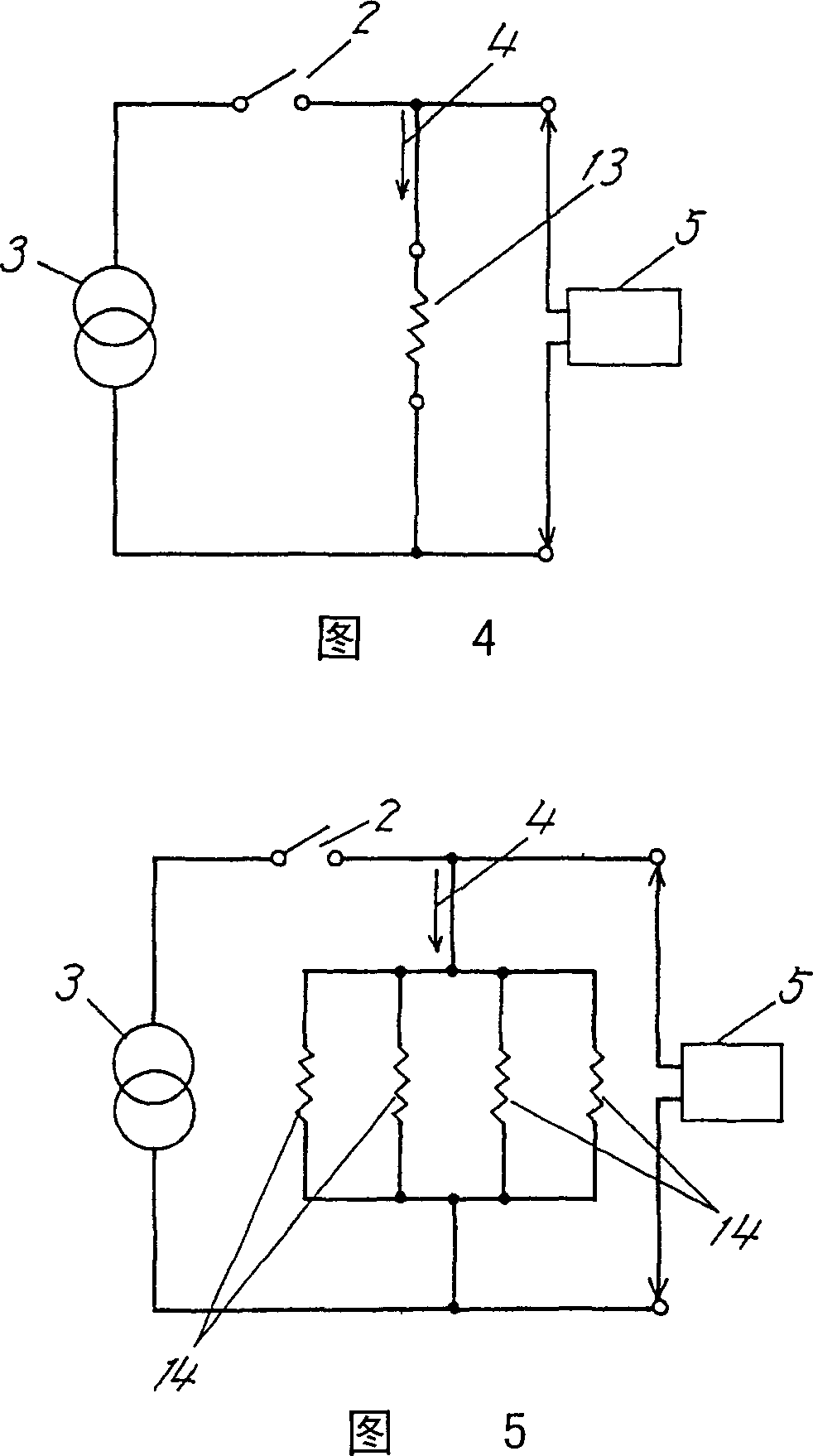

[0024] First, prepare a laminated ceramic capacitor with a length of 1.6 mm, a width of 0.8 mm, a thickness of 0.8 mm, an electrostatic capacitance of 0.22 μF, and a rated voltage of 16 V according to the known manufacturing method of the laminated ceramic capacitor 1. A capacitor manufactured by using Ni as the inner electrode 7, Cu as the outer electrode 6, and using a ceramic material with B characteristics on the active layer 8.

[0025] Next, a description will be given of a process in which a direct current 4 is applied superimposedly to the manufactured multilayer ceramic capacitor, and when a voltage is generated between the external electrodes 6, the multilayer ceramic capacitor achieves dielectric breakdown. In addition, the DC constant current 4 that has been energized by superimposition does not leak due to the humidity attached to the surface of the multilayer ceramic capacitor 1, and a voltage is generated between the external electrodes 6. In order to apply this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com