Method for producing granular cryolite

A production method and cryolite technology, which are applied in the directions of die extrusion granulation, aluminum fluoride, aluminum halide, etc., can solve the problems of restricting the technological progress and healthy development of the aluminum electrolysis industry, unfavorable automatic blanking and environmental protection requirements, and large flying losses. And other problems, to achieve the effect of pure appearance color, not easy to break, less flying loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

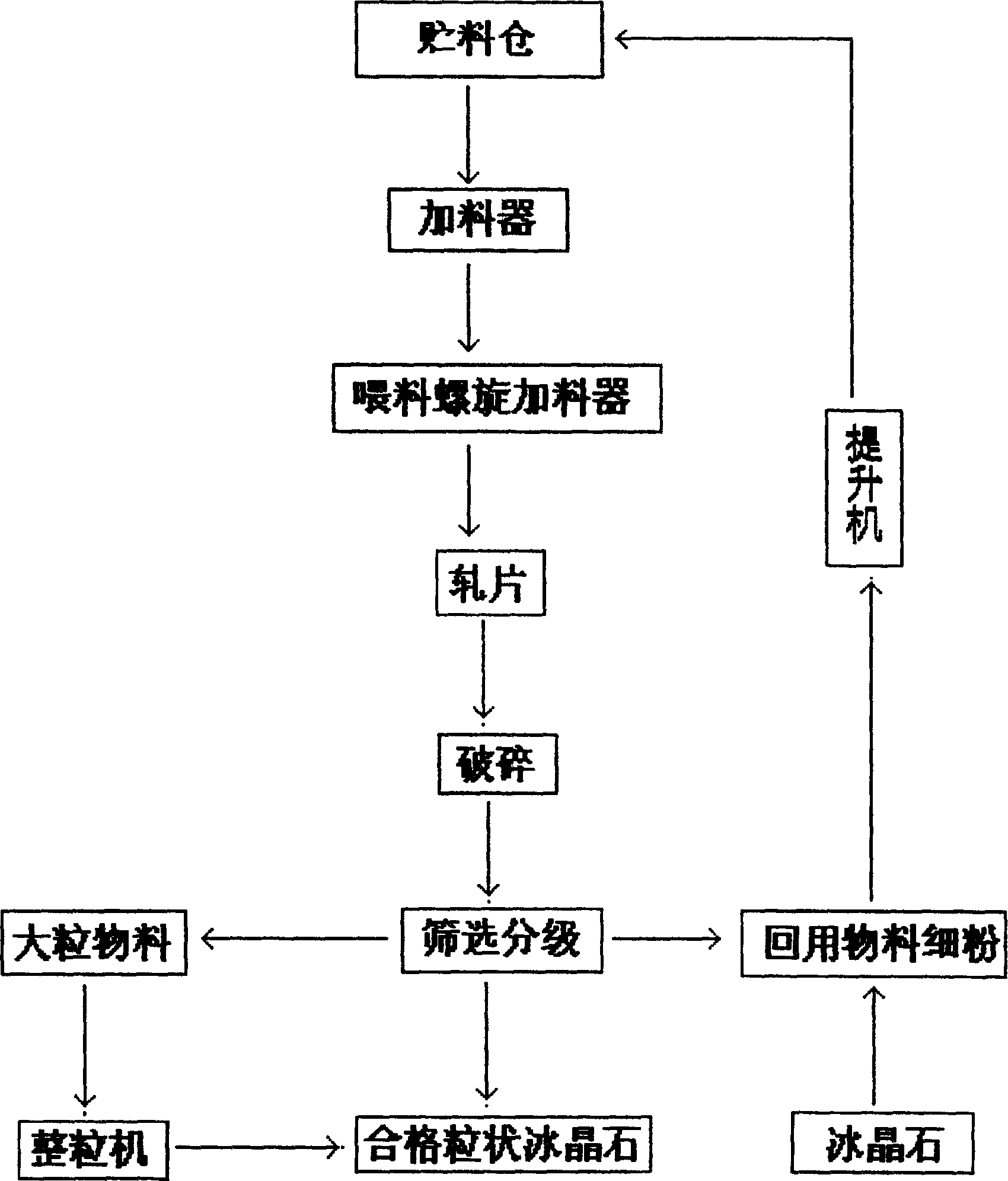

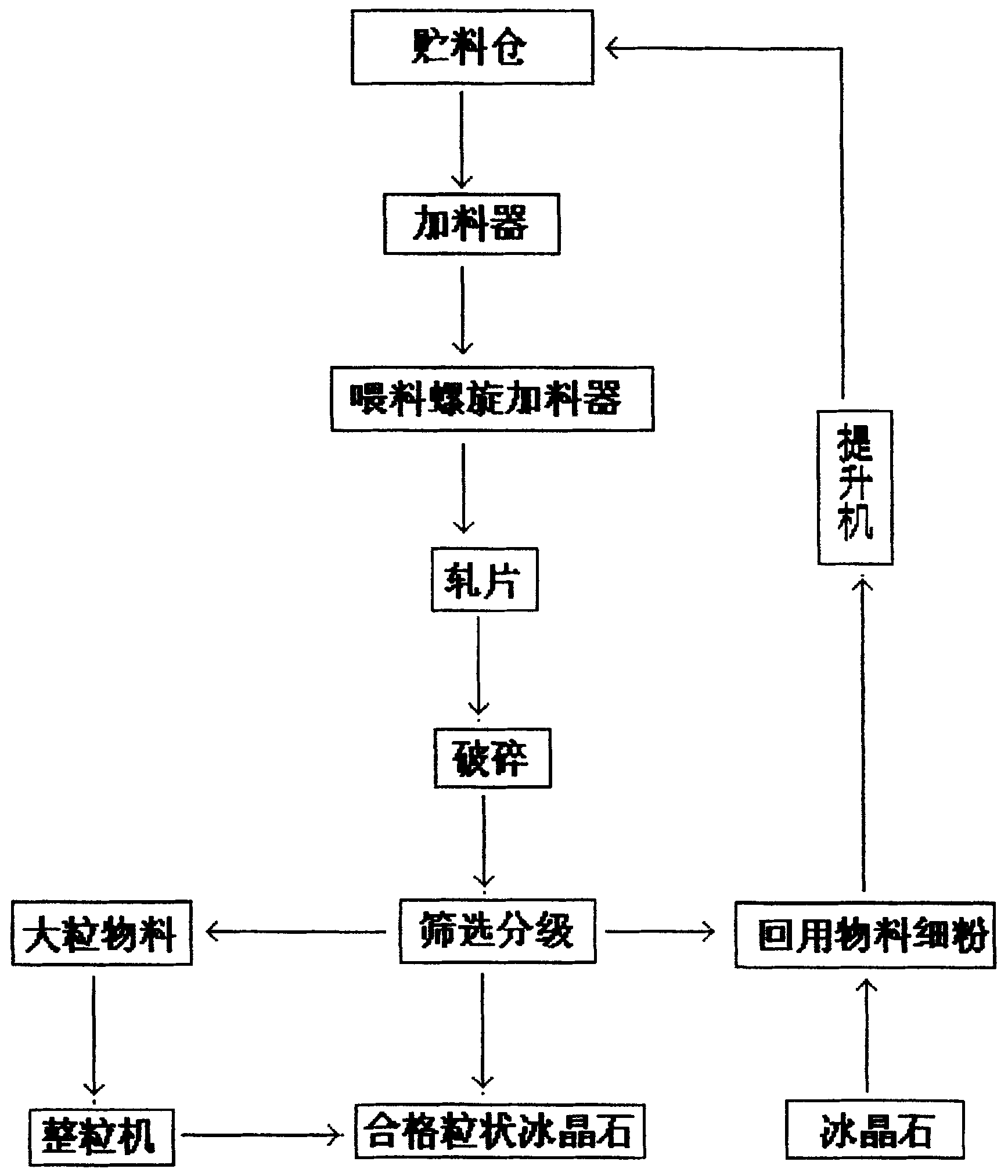

[0013] Such as figure 1 Shown, the production method of granular cryolite of the present invention comprises the following steps: add the qualified cryolite to the storage device with the lifting device, quantitatively add the material to the feeding screw feeder by the star feeder, and according to the granulation situation Adjustment: timely adjust the rotation frequency of the feeding screw, so that the cryolite enters the gap between the two rolls of the granulation device with a certain pressure, one set of roll shaft seats is fixed, and the other set of roll shaft seats slides, and the two are separated by hydraulic pressure. Close to each other, with the continuous operation of the rollers, the cryolite is extruded into flake materials; the flake materials are crushed by the crusher and enter the vibrating screen, the qualified granular materials are sent to the finished product post, and the cryolite fine powder is returned to the storage by the lifting device The devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com