Preparation method of CuCrZr spherical powder for 3D printing

A spherical powder and 3D printing technology, which is applied in the field of metal powder manufacturing, can solve the problems that alloy powder is difficult to apply, and achieve the effect of avoiding micro-pores and micro-cracks, uniform and adjustable powder particle size, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

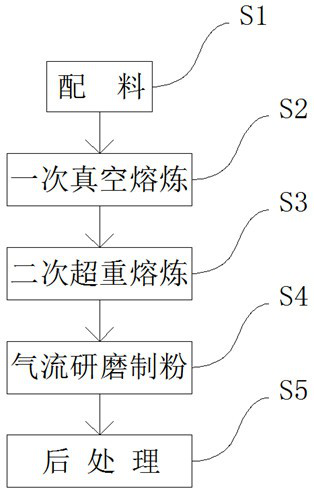

[0038] A method for preparing CuCrZr spherical powder for 3D printing, comprising the following steps:

[0039] S1. Ingredients: Prepare raw materials according to requirements. The raw materials are calculated according to mass percentage: 1% of metal chromium block, 0.045% of zirconia powder, 0.25% of 20% mass concentration of zirconia dichloride octahydrate, and the balance is electrolytic copper plate. The purity of metal chromium block is 99.97%;

[0040] The preparation method of zirconia powder is:

[0041] S1-1: Mix zircon concentrate powder with flake graphite, pyrolytic graphite and calcite at a mass ratio of 23:6:5:2, put them into a grinder and grind them until the particle size is less than 0.5mm to obtain a mixed powder ;

[0042] S1-2: Place the ground mixed powder in an electric arc furnace, arc smelt at 2740°C for 2.5 hours, then quench the temperature to 555°C, use liquid nitrogen to cool down, and the cooling rate is 190°C / h to obtain zirconium-rich crys...

Embodiment 2

[0054] The difference between this embodiment and embodiment 1 lies in that the distribution ratio of each component of the ingredients in step S1 is different.

[0055] S1. Ingredients: Raw materials are prepared according to the requirements. The raw materials are calculated according to mass percentage: 0.9% of metal chromium block, 0.04% of zirconia powder, 0.2% of 20% mass concentration of zirconia dichloride octahydrate, and the balance is electrolytic copper plate. The purity of the metallic chromium block is 99.95%.

Embodiment 3

[0057] The difference between this embodiment and embodiment 1 lies in that the distribution ratio of each component of the ingredients in step S1 is different.

[0058] S1. Ingredients: Raw materials are prepared according to the requirements. The raw materials are calculated according to mass percentage: 1.1% of metal chromium block, 0.05% of zirconia powder, 0.3% of 20% mass concentration of zirconia dichloride octahydrate, and the balance is electrolytic copper plate. The purity of the metallic chrome block is 99.99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com