Quasi-micelle superparamagnetic nano particles and preparation method thereof

A superparamagnetic and nanoparticle technology, which is applied in capsule delivery, microcapsules, pharmaceutical formulations, etc., can solve the problem of being easily affected by factors such as solution polarity, pH, and ion concentration, and it is difficult to form regular size and shape polymer gels. In order to avoid problems such as uneven molecular weight of bundles and block copolymers, it can achieve the effects of secondary assembly, uniform and adjustable particle size, and easy purification and collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

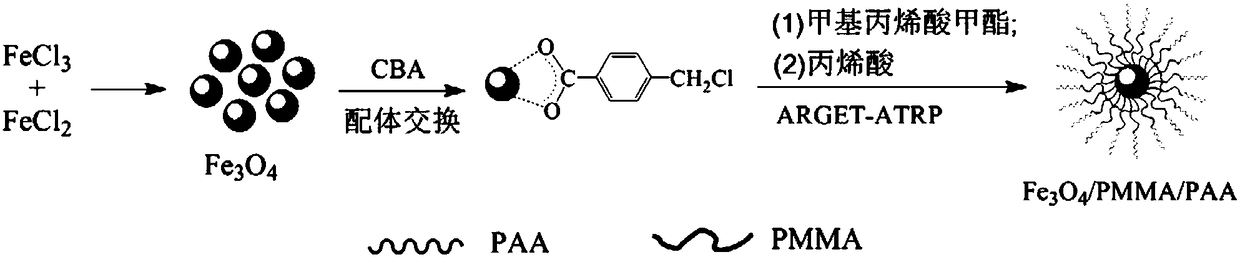

[0032] Example 1: Preparation of hydrophobic-hydrophilic micellar superparamagnetic nanoparticles Fe 3 o 4 / PMMA / PAA

[0033] 1. Co-precipitation method to prepare superparamagnetic Fe 3 o 4 Nanoparticles

[0034] 397.62mg (2mmol) FeCl 2 4H 2 O, 946.05 mg (3.5 mmol) FeCl 3 ·6H 2 O was dissolved in an appropriate amount of water and injected sequentially into the anaerobic reaction system, and then deionized water was added to make the final volume 80 mL. Slowly raise the temperature to 80°C under mechanical stirring (800rpm), slowly dropwise add ammonia water (5mL, 4mmol / L) to the reaction system, keep warm for 1 hour after the dropwise addition, and then stop heating. After the reaction solvent was cooled to room temperature, the product was transferred to an Erlenmeyer flask, magnetically separated, and washed three times with deionized water to obtain superparamagnetic Fe 3 o 4 nanoparticles.

[0035] 2. Preparation of Chloromethylated Superparamagnetic Fe Nanopa...

Embodiment 2

[0042] Example 2: Preparation of hydrophilic-hydrophobic micellar superparamagnetic nanoparticles Fe 3 o 4 / PMMA / PAA

[0043] 1. Co-precipitation method to prepare superparamagnetic Fe 3 o 4 Nanoparticles

[0044] 397.62mg (2mmol) FeCl 2 4H 2 O, 946.05 mg (3.5 mmol) FeCl 3 ·6H 2 O was dissolved in an appropriate amount of water and injected sequentially into the anaerobic reaction system, and then deionized water was added to make the final volume 80 mL. Slowly raise the temperature to 80°C under mechanical stirring (800rpm), slowly dropwise add ammonia water (5mL, 4mmol / L) to the reaction system, keep warm for 1 hour after the dropwise addition, and then stop heating. After the reaction solvent was cooled to room temperature, the product was transferred to an Erlenmeyer flask, magnetically separated, and washed three times with deionized water to obtain superparamagnetic Fe 3 o 4 nanoparticles.

[0045] 2. Preparation of Chloromethylated Superparamagnetic Fe Nanopa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com