Air-gap axial generator

An axial air gap, power generation device technology, applied in the direction of electromechanical devices, electrical components, magnetic circuit shape/style/structure, etc. Reduce the time for alignment and bearing installation alignment, and the effect of isolating corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The magnetic induction effect generated by the interaction between the magnetic field and the electric field was discovered by Faraday. Faraday found that when the conductor cuts the magnetic force line, that is, when the conductor passes through the magnetic force line, the conductor will generate an induced electromotive force.

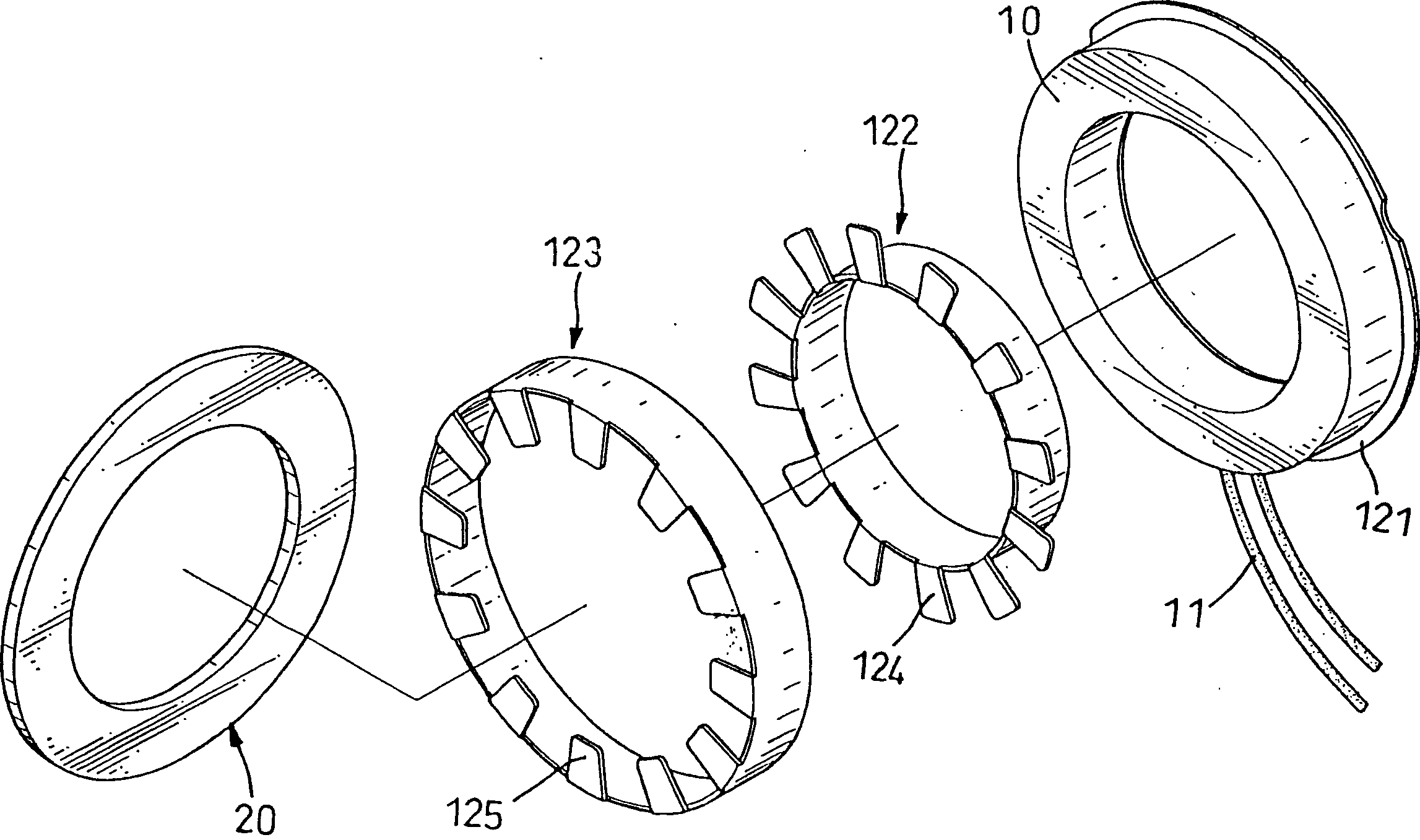

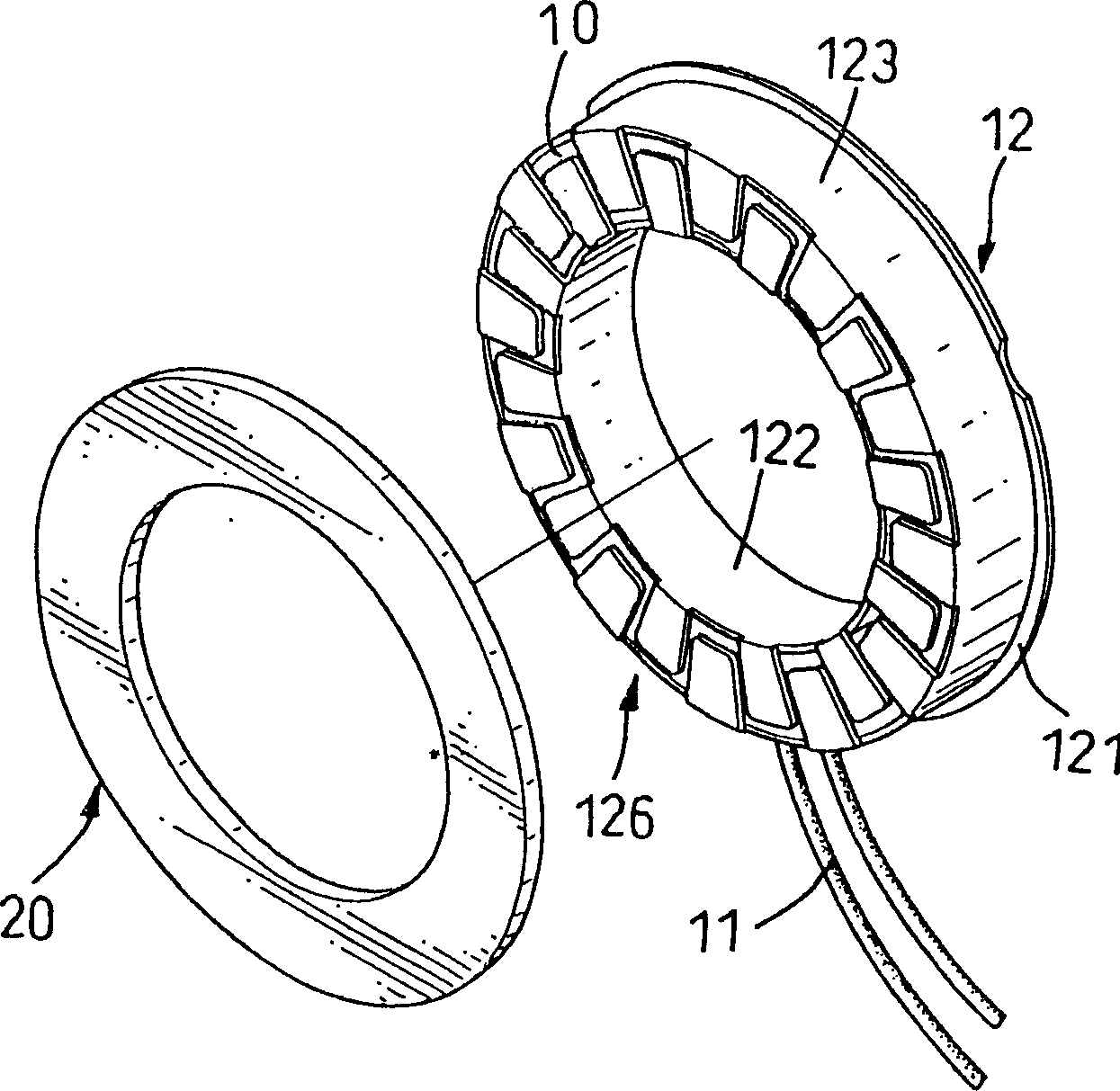

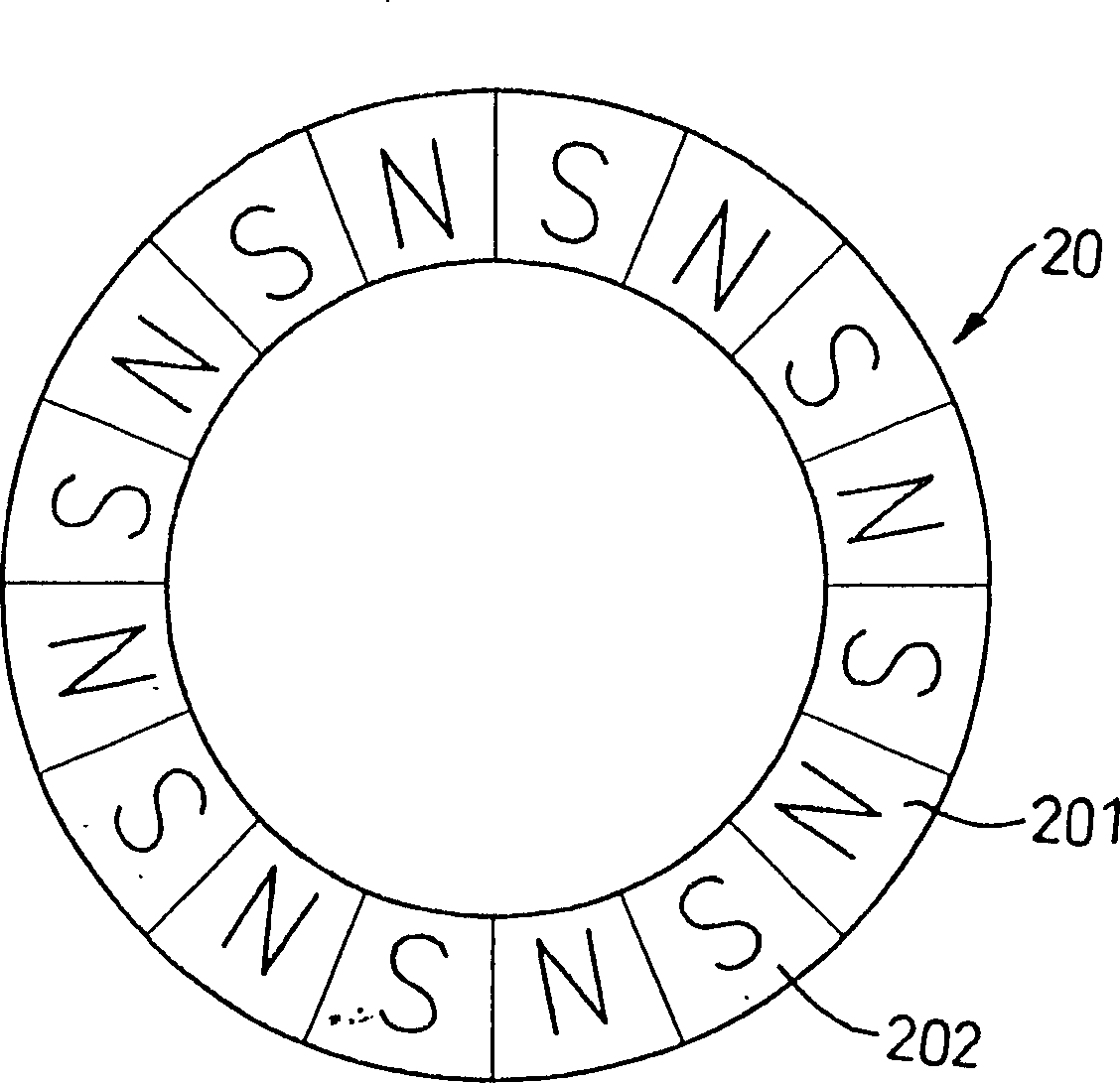

[0022] Such as figure 1 , figure 2 As shown, based on the above principles, the present invention includes an induction coil 10 , a coil base 12 for accommodating the induction coil 10 and a magnet structure 20 .

[0023] The induction coil 10 is formed by winding a conductive coil to form an annular ring, which leads to two conductive wires 11 .

[0024] The coil base 12 includes a base 121 disposed on one side of the induction coil 10 , an inner pole cover 122 and an outer pole cover 123 respectively sleeved on the inner and outer edges of the induction coil 10 .

[0025] The base 121 is an annular thin disk made of metal material. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com