Disk drive incorporating vibration suppressing mechanism

An optical disc drive, optical disc technology, applied in vibration suppression adjustment, rotational vibration suppression, electromechanical devices, etc., can solve the problems of difficulty in leaving the sphere 13, reading errors, etc., and achieve the effect of reducing the effect of eccentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

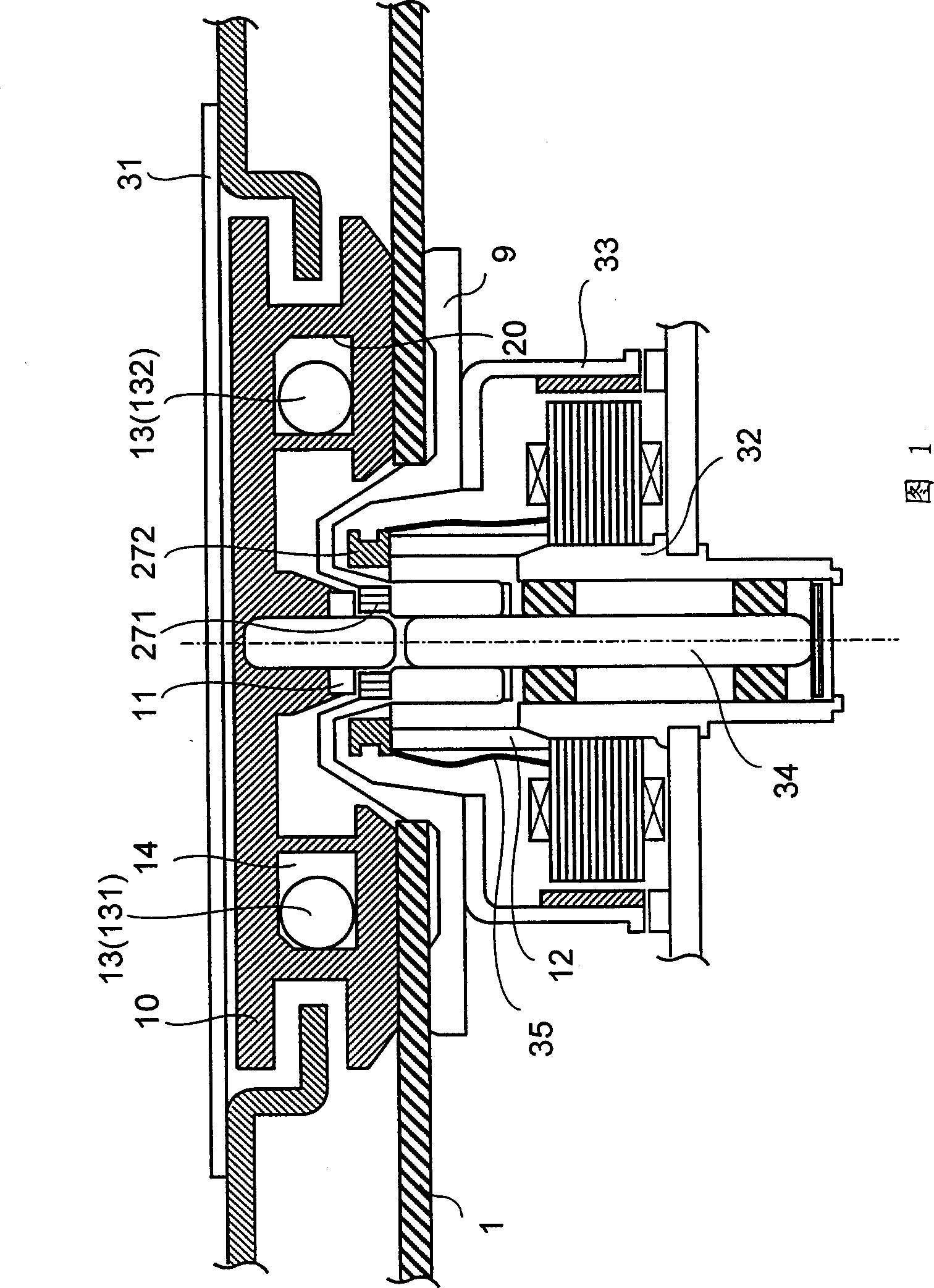

[0040] Fig. 1 is a side sectional view of the main part of an optical disk drive device according to Embodiment 1 of the present invention, showing an example in which an electromagnet is arranged on a fixed part of a spindle motor.

[0041] Components having functions similar to those of the above conventional examples use the same symbols.

[0042] In this example 1, with Figure 6 The disc drive device of the conventional example shown is different in the following points.

[0043] Magnet 271 is smaller than existing ones, and is located on the turntable. A yoke 11 is provided on the clamp 10, and the yoke 11 and the magnet 271 face each other through a gap. The optical disk 1 is clamped between the clamper 10 and the turntable 9 by the attractive force between the magnet 271 and the yoke 11 . In addition, the electromagnet 272 is operated to eliminate the imbalance of the optical disk 1, and this electromagnet is used as a magnetic generator for electromagnetic conversi...

Embodiment 2

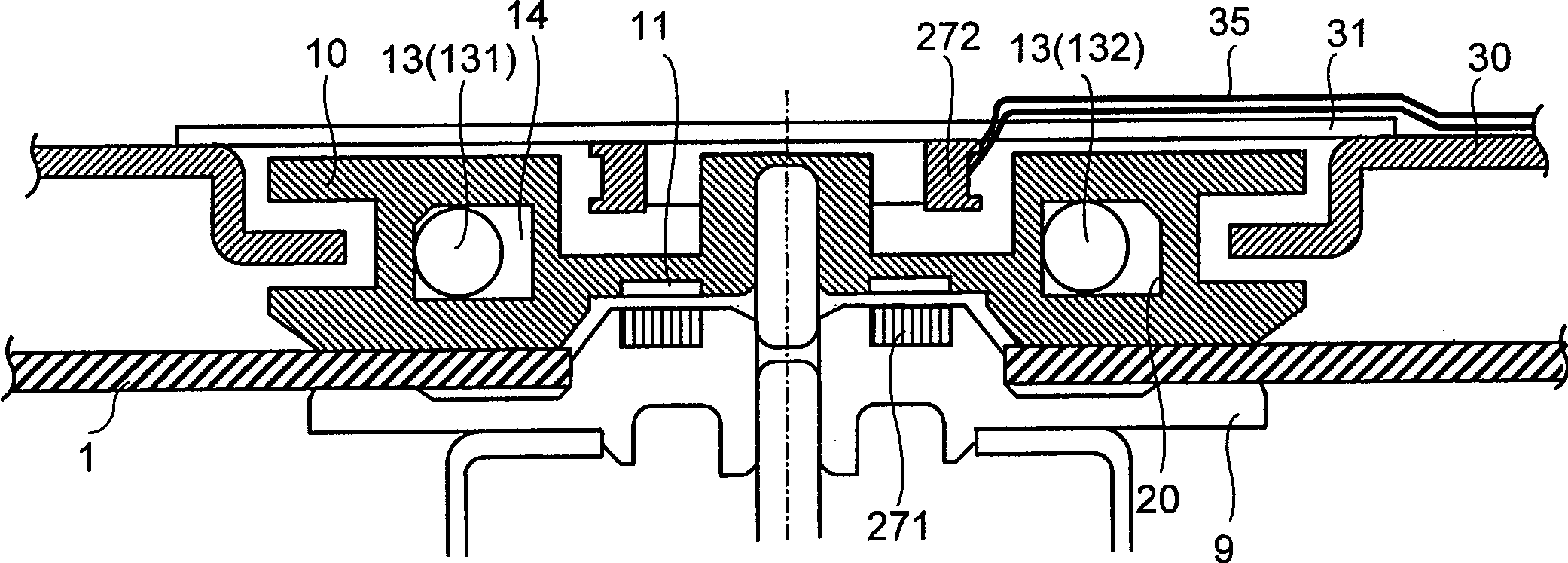

[0054] figure 2 It is a side sectional view of main parts of an optical disk drive device according to Embodiment 2 of the present invention, and is an example in which an electromagnet is provided on a stopper protection plate.

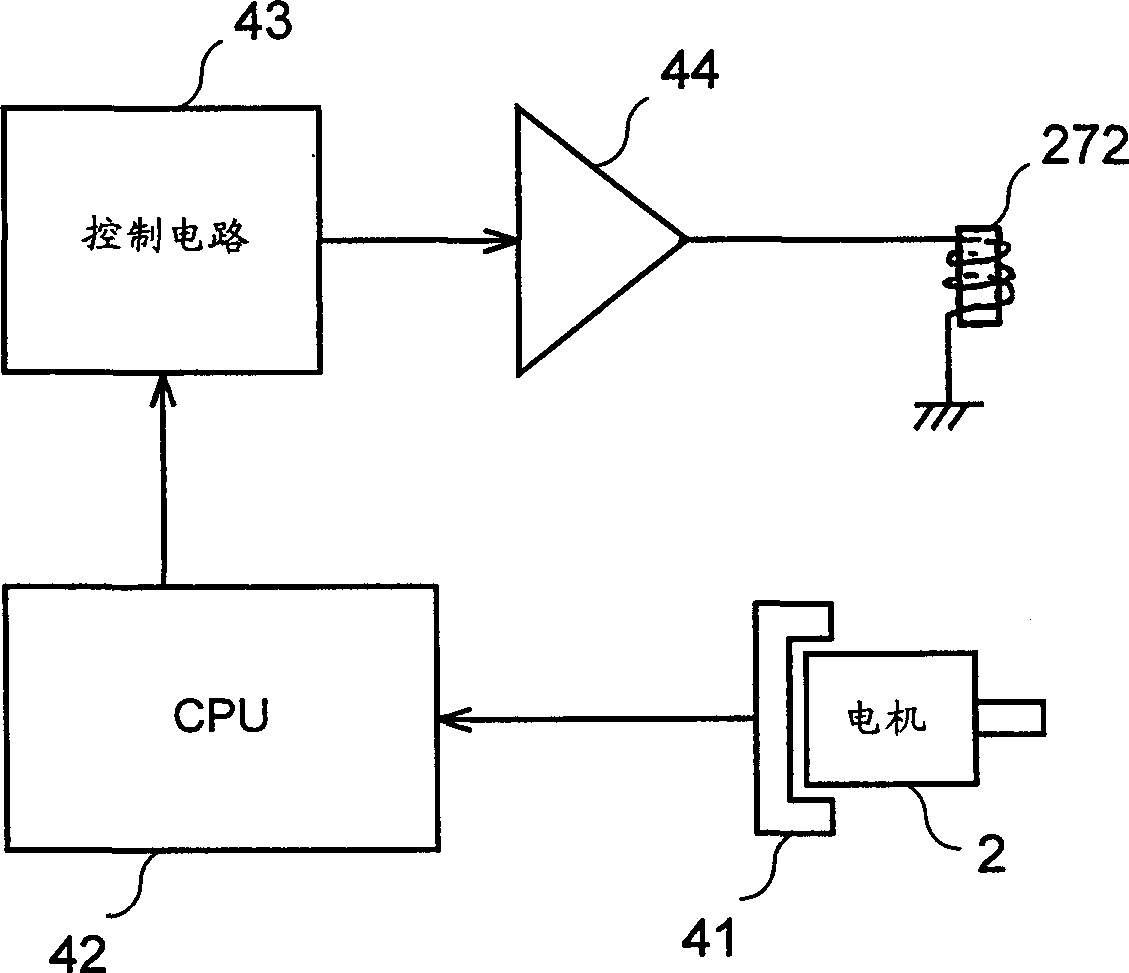

[0055] Figure 4A It is a diagram showing the change of the rotational speed of the disc with time when the disc changes from low speed to high speed, and a pulse waveform diagram showing the corresponding change of the duty of the pulse applied to the electromagnet with time, Figure 4B It is a graph showing the change with time of the rotational speed of the disc when the disc changes from high speed to low speed, and a pulse waveform showing the change with time of the duty of the pulse applied to the electromagnet corresponding thereto.

[0056] figure 2 Among them, the retainer protection plate 31 is arranged on the upper part of the retainer 10 . The cylindrical electromagnet 272 is fixed on the lower side of the retainer protection plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com