Improvements to spiral heat exchangers

A heat exchanger, spiral technology, applied in the field of spiral heat exchangers, can solve problems such as difficult operation, and achieve the effect of simplified methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

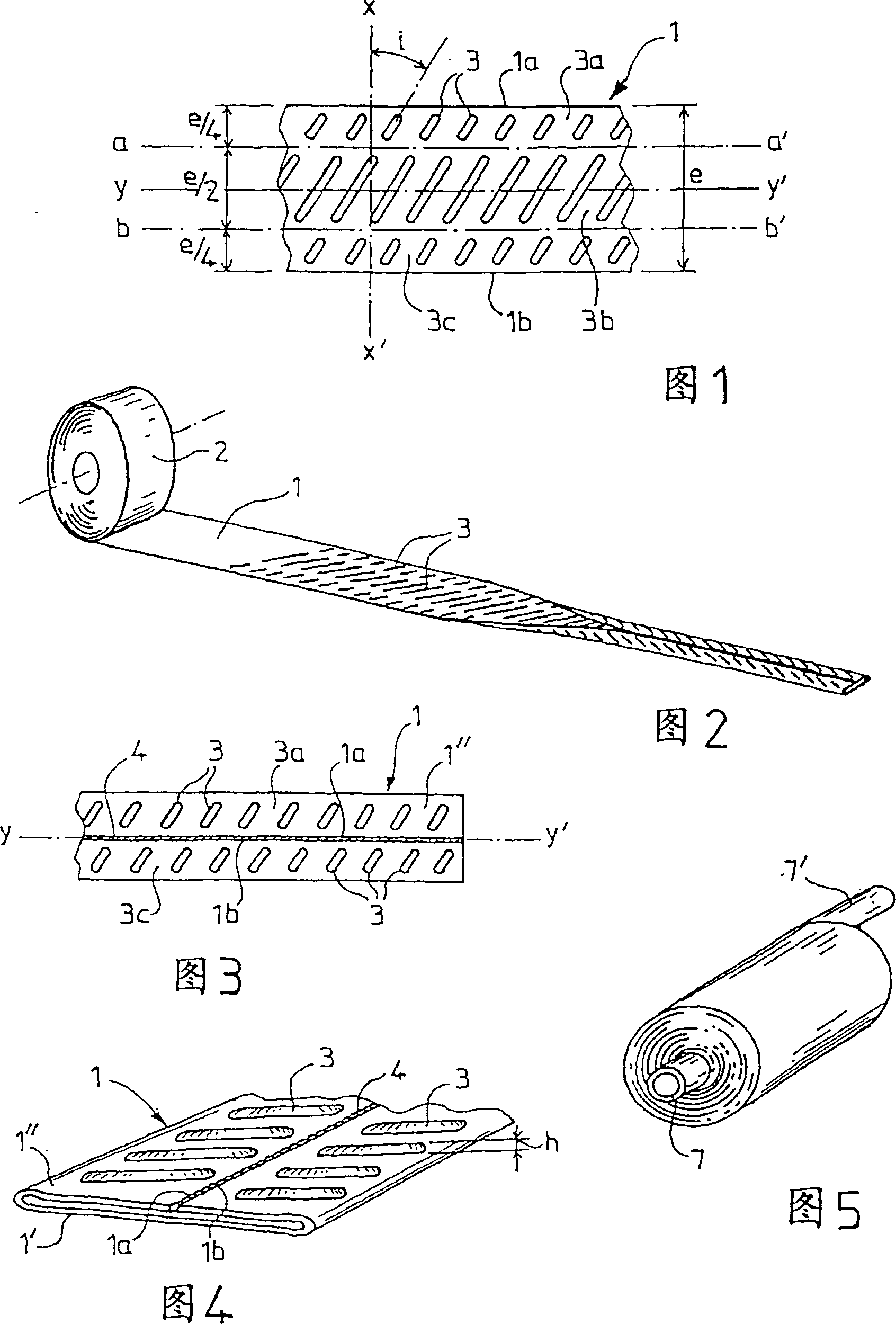

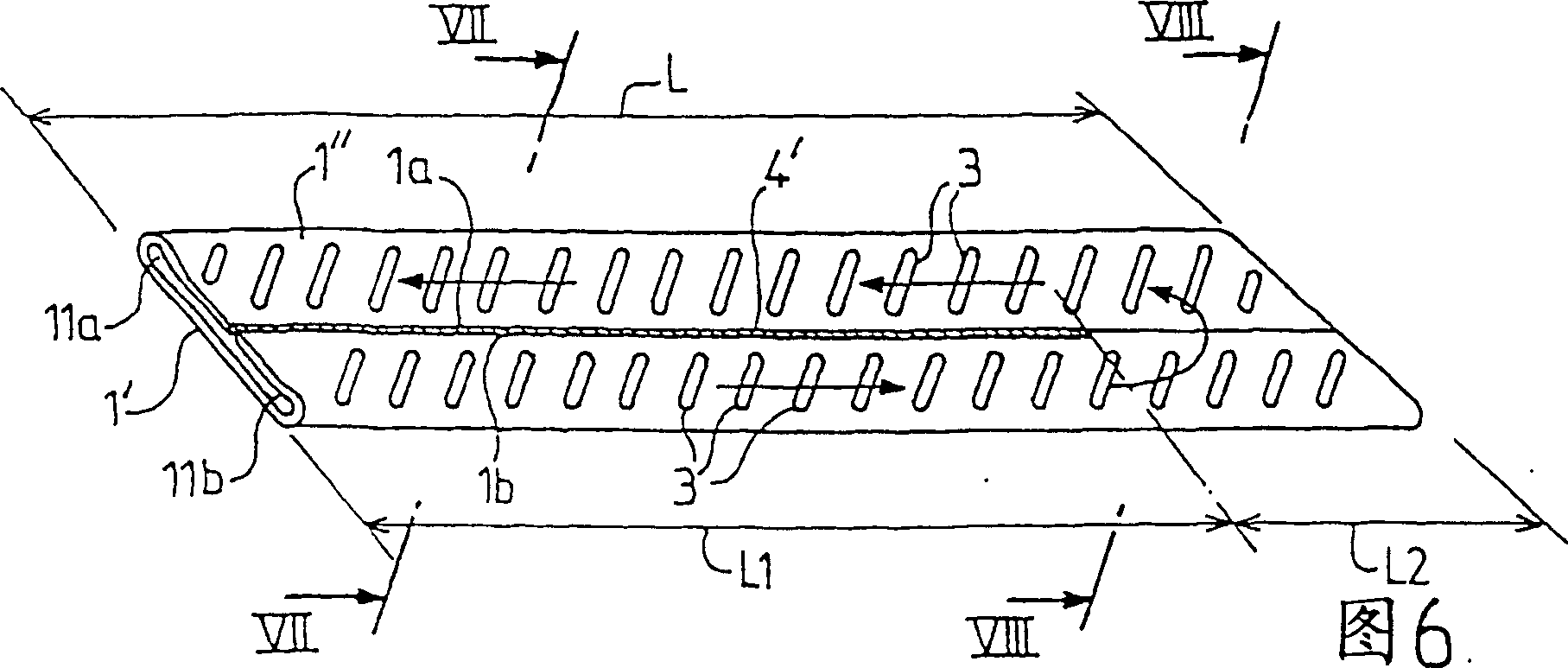

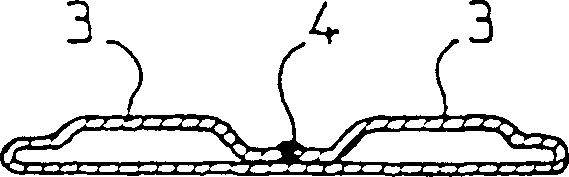

[0029] The spiral metal heat exchanger according to the invention is constructed starting from a metal sheet 1 , in particular made of stainless steel sheet metal, which is supplied to the user in the form of a sheet coil 2 . Each reinforcing rib 3 is formed on the metal plate 1, and these reinforcing ribs 3 are obtained by press forming. These stiffeners 3 form an angle of attack with the transverse axis XX' of the metal sheet 1 i , in this example, the angle of attack i About 45°. Each reinforcing rib 3 is distributed on three lateral areas, that is, a length substantially equal to the width of the metal sheet 1 e A quarter of the first transverse zone 3a, a length substantially equal to the width of the metal sheet 1 e half of the central region 3b, and a length substantially equal to the width of the metal sheet 1 e A quarter of the third lateral zone 3c. The height of these ribs 3 h Equal to half of the space desired to be provided between the spiral wound layers at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com