Method for producing a thermoplastic coating and articles constructed therefrom

A coating method and coating technology, which is applied in the field of non-contact gap coating for the manufacture of various coatings and layered products, and can solve problems such as interference with coating adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

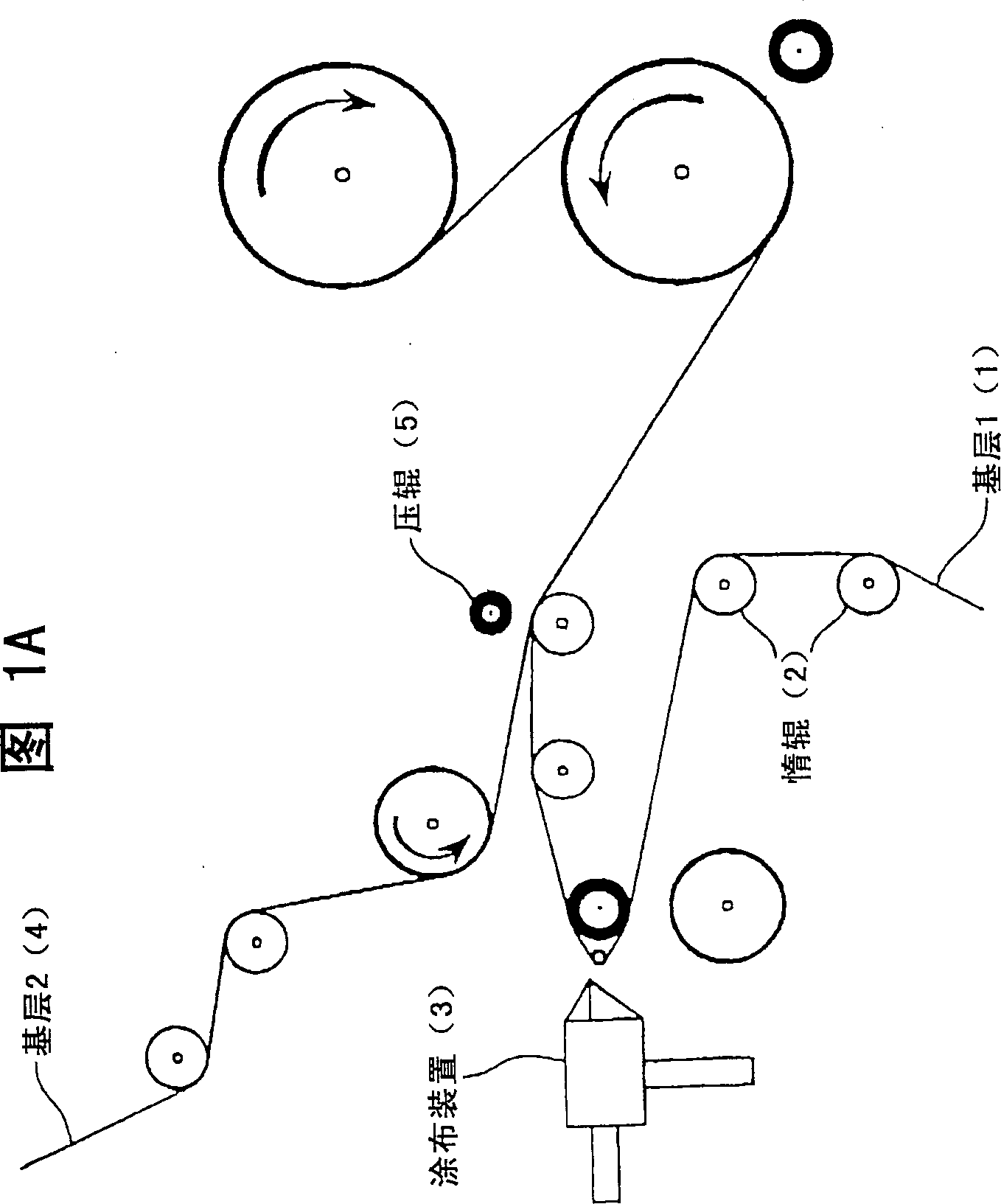

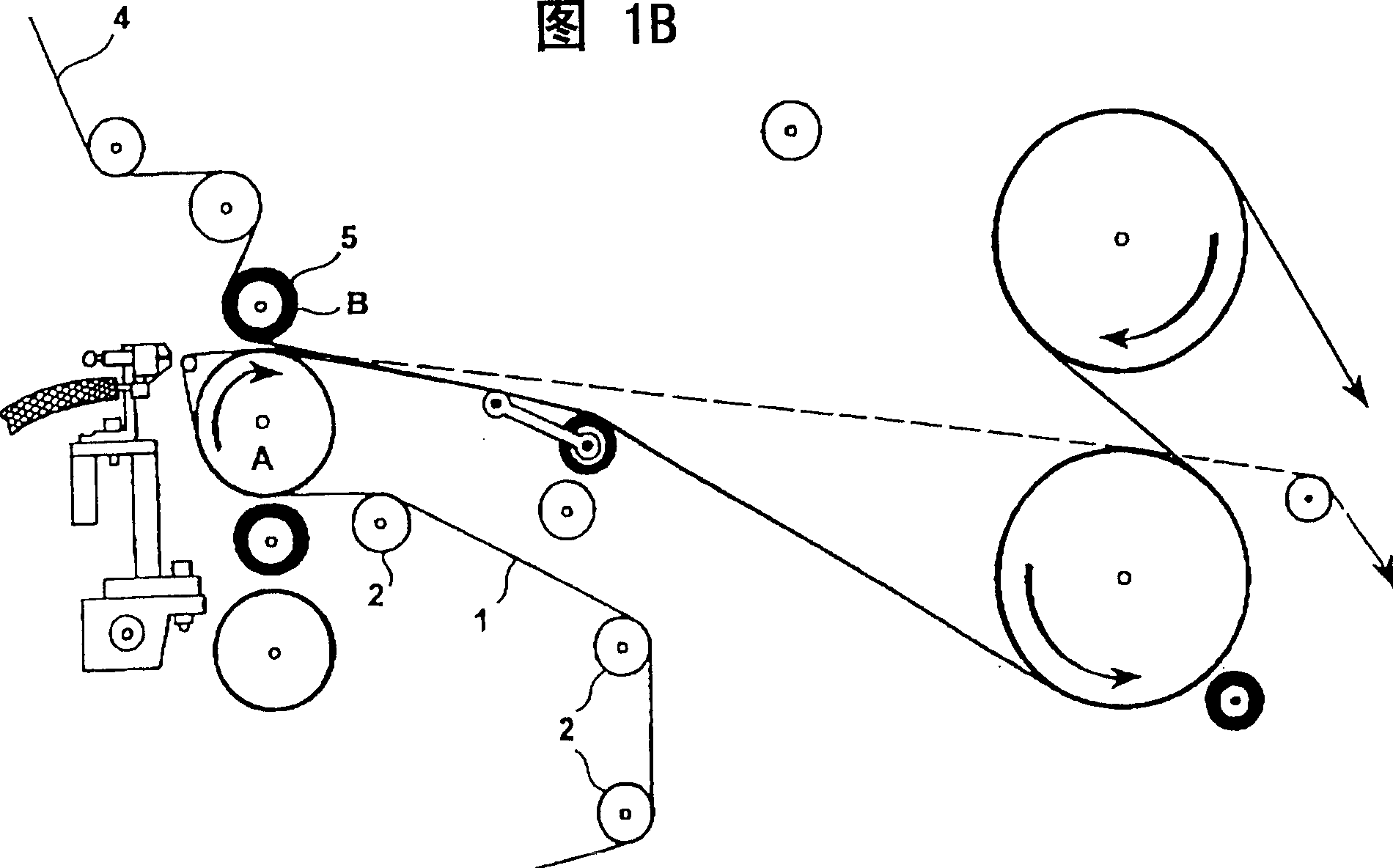

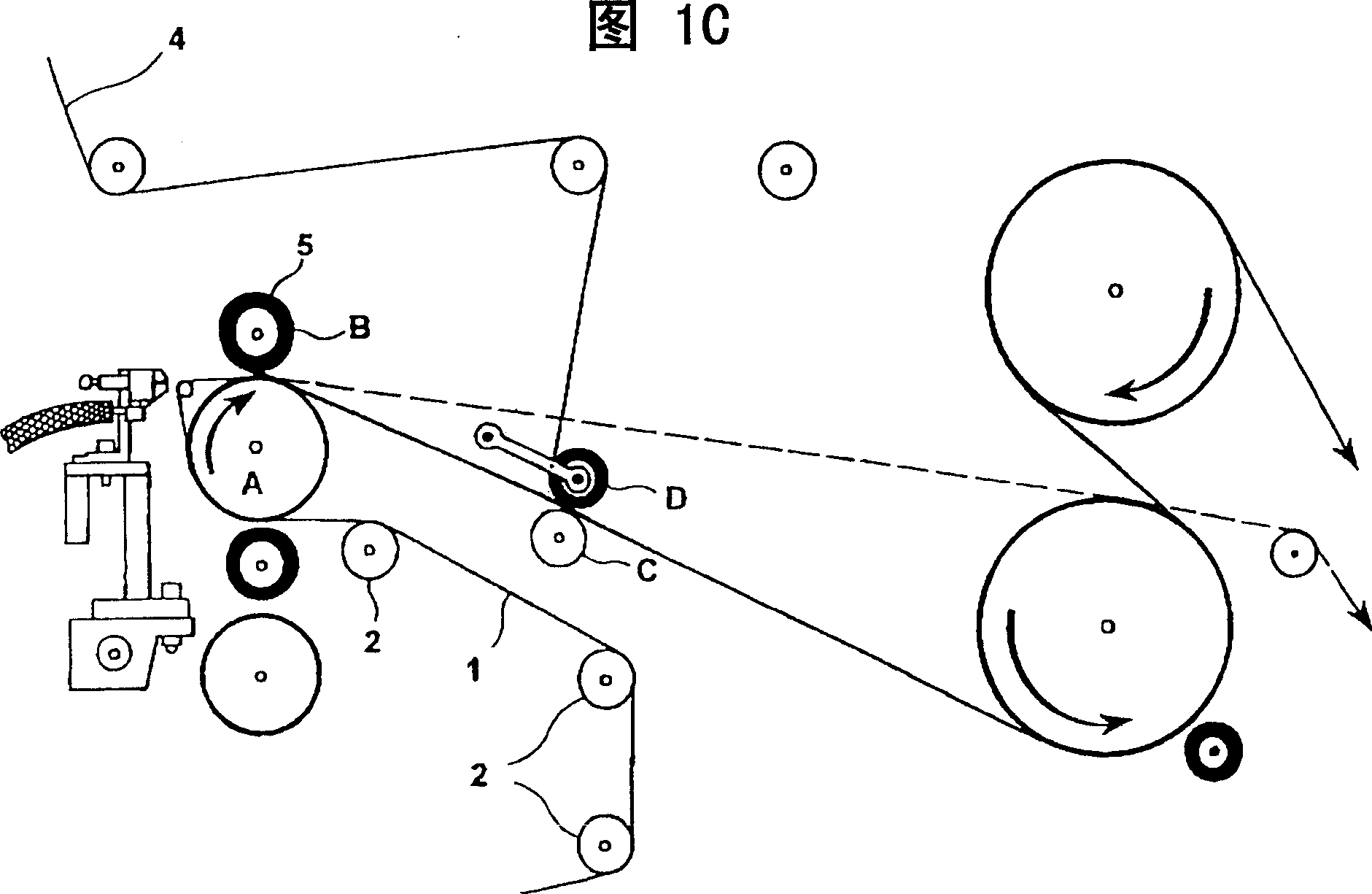

[0078] Hot-melt adhesives corresponding to the components described in Examples and 1 and 7 were coated on the base layer using a modified PAK600 laminator from Krosnert Hamburg, Germany, the structure of which was basically the same as that shown in Figure 1B machines are similar. With this machine, the adhesive film is pressed directly onto the first base layer 1 by means of the pressing roll 5 or the second base layer 4 is pressed onto the first base layer and the adhesive, still via the pressing roll 5 . In the experiment, both methods will be tried. The dosing temperature of the hot melt was 140°C for the composition of Example 1 and 110°C for the composition of Example 7. As can be seen from Chart 14, these compositions exhibit suitably lower viscosities. This graph illustrates the viscosities in 1 and 7 above.

[0079]Coatings were formed on polyester films (Polyester RN 36 produced by Püitz Folien, Taunusstein-Wehen, Germany) and high density polyethylene fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface density | aaaaa | aaaaa |

| surface density | aaaaa | aaaaa |

| surface density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com