3-limb amorphous metal cores for three-phase transformers

A transformer core, amorphous technology, applied in the direction of transformer/inductor core, transformer, inductor/transformer/magnet manufacturing, etc., can solve the problem of reducing the operating efficiency of the excitation power transformer, and achieve the effect of reducing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0101]An amorphous metal transformer core having the same dimensions as those produced in Comparative Examples 3 and 4 was manufactured according to the present invention. Two identically sized inner cores were produced according to known prior art from non-annealed amorphous alloy strip (METGLAS 2605 SAI, 142 mm wide) and inserted into a prepared outer core. After they were assembled in their unannealed state, the three-core transformer cores were heated to a temperature of 340-355°C in the presence of a magnetic field inserted through the two cores as shown in Figure 6. The two-turn induction of a wire in the external window produces a current of 700 amps with a DC current of about 4 volts, and the resulting field strength is the same as that of comparative examples 3 and 4. After heating to the above temperature, stay in the furnace at this temperature for 30 minutes to ensure thorough heating and annealing. Thereafter the assembled, annealed, three-core transformer core w...

example 2

[0104] The second three-core transformer core as shown in Fig. 6 is manufactured with the same materials and methods as in Example 1. But after reaching a temperature of 340-355° C., the heated transformer core was kept at this temperature for 60 minutes, 30 minutes more than ratio 1. During the annealing process, a DC current of 700A at a voltage of about 4V was passed through the two core windows to generate the required magnetic field. After annealing, the transformer core is taken out and cooled to room temperature (about 20°C). Similar to the above, the core loss is determined to be 0.285w / kg, and the total mass of the transformer core after annealing is 156kg. Afterwards, all the joints of the three cores were opened, and then refitted to reconstruct the annealed three-core transformer core. The core loss obtained in this test was 0.274w / kg. While there was an unusual reduction in core loss this time around after joint re-mating, the difference in terms of volume was o...

example 3

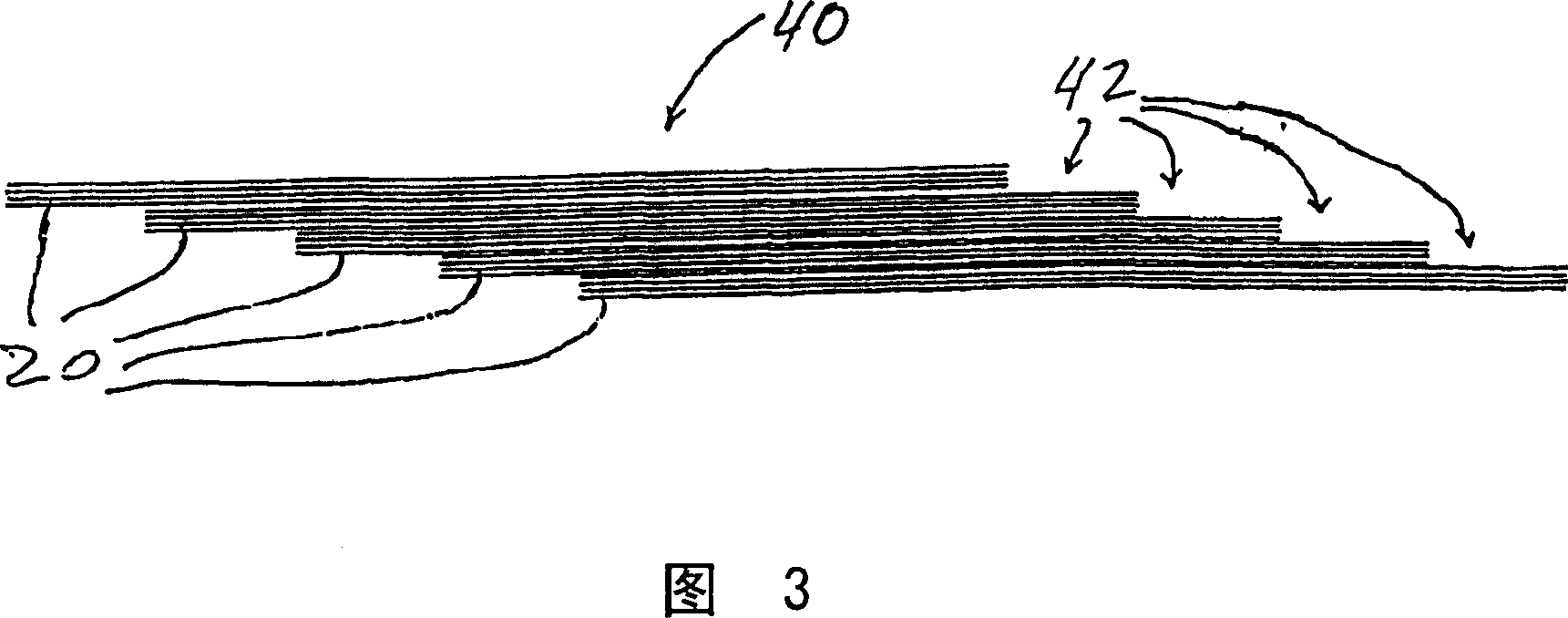

[0114] A three-core transformer core as shown in Figures 9 and 10 was fabricated according to the process of the present invention. The transformer core was made of amorphous alloy strip (METGLAS 2605 SAI, 170 mm wide) without annealing.

[0115] The transformer core consists of three cores, namely two inner cores of different sizes and a third outer core, and these three cores are composed of "C-shaped parts", "I-shaped parts" and "I-shaped parts" of appropriate size and preassembled. ” and “straight portion” and assembled into the shape shown in Figure 10 before annealing.

[0116] Thereafter, the assembled three-core transformer core is introduced into a suitable furnace and raised to a temperature of 340-355°C. At the same time, a wire is looped through the two core windows, and a DC current of 2100 amps is fed into the wire with a voltage of about 5 volts, which ensures that a consistent magnetic field is excited in the transformer core. After reaching a temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com