Kitchen refuse disposal system

A technology of kitchen waste and treatment system, applied in the field of kitchen waste treatment system, can solve the problems of huge, difficult to fully ensure the installation area, increase the burden of public sewage treatment facilities, etc., and achieve the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

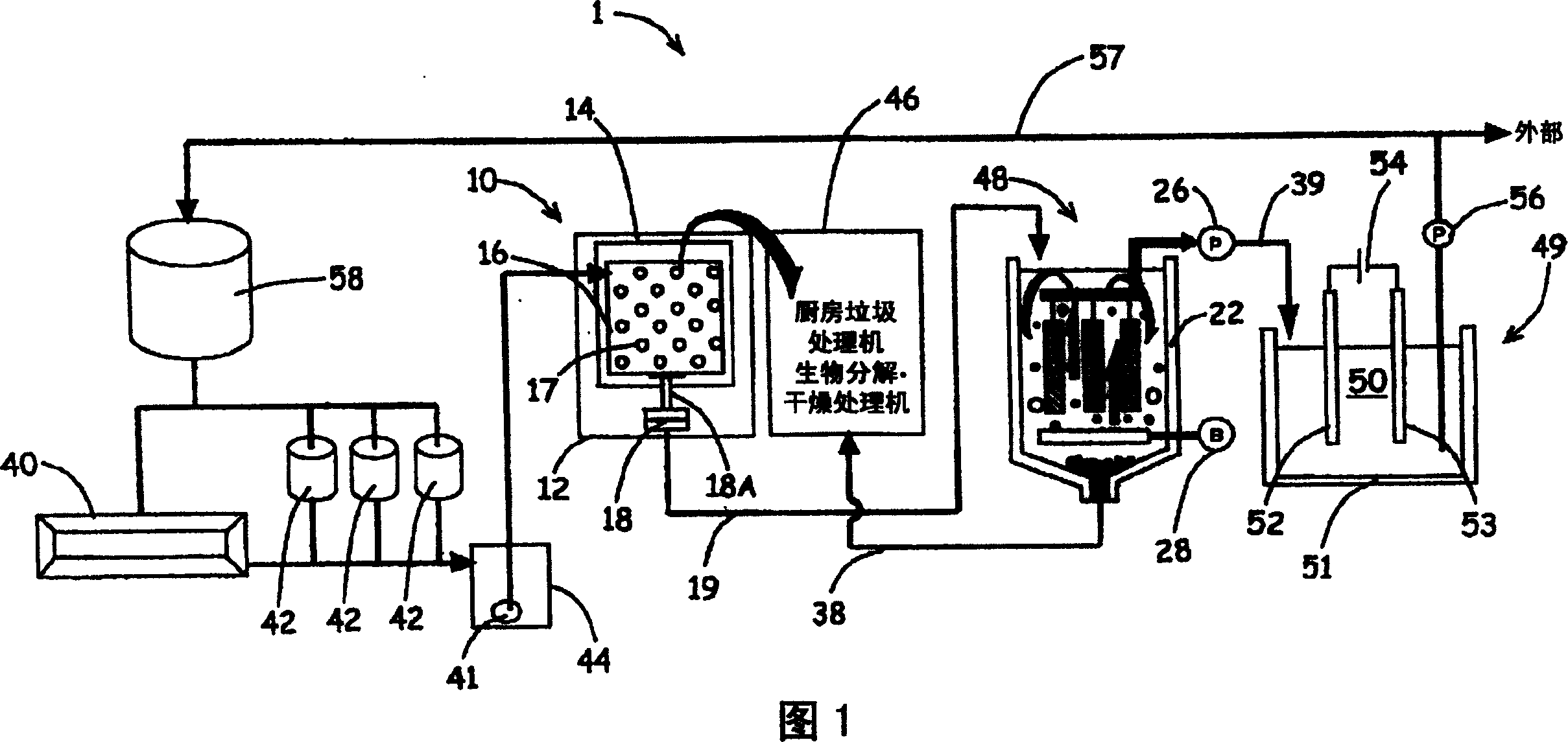

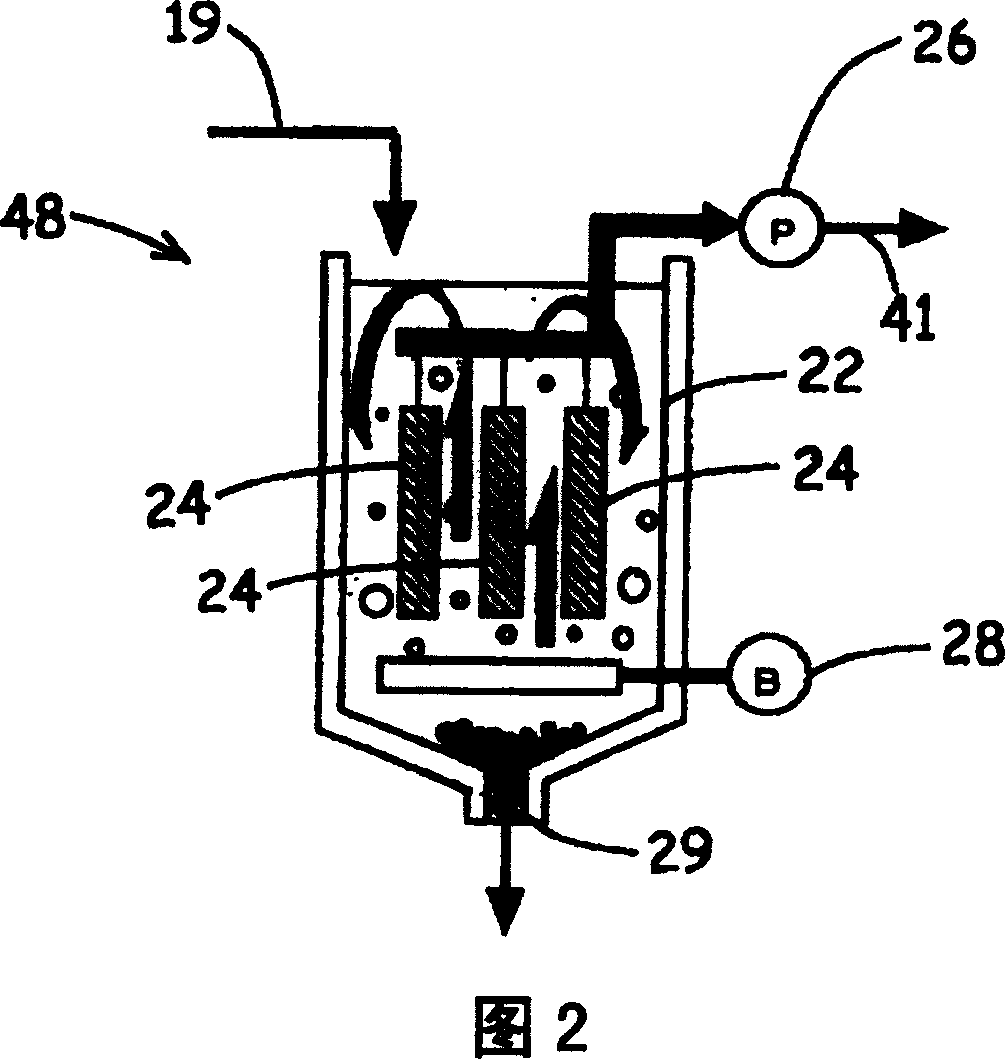

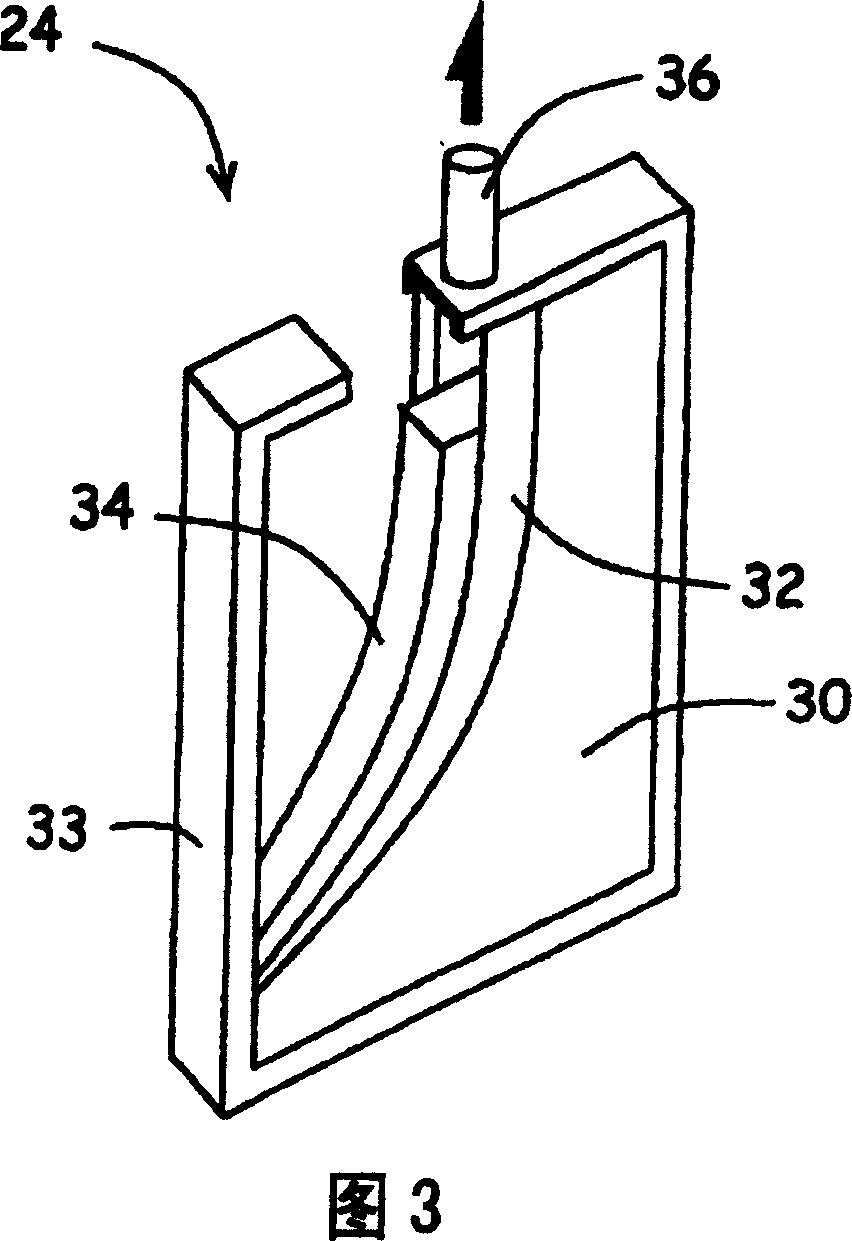

[0043] The present invention is obtained to solve the problems in the prior art, and it provides a kitchen waste treatment system capable of reliably treating the water separated by a solid-liquid separation device and reducing the burden on public sewage treatment facilities. One embodiment of the present invention will be described in detail below based on the drawings. Fig. 1 is a schematic diagram of a kitchen waste treatment system 1 of the present invention, Fig. 2 is a schematic cross-sectional view of a membrane separation activated sludge device 48, and Fig. 3 is a part of a microporous film 24 arranged on a membrane separation activated sludge device 48 Notched stereogram.

[0044] The kitchen waste processing system 1 of the present embodiment is a processing system for processing kitchen waste such as kitchen waste discharged from hotels or restaurant kitchens and other organic inclusions. A description will be given of a case where garbage discharged from the gar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com