Permanent magnet punching machine

A technology of permanent magnets and punching machines, applied in the direction of punching machines, presses, manufacturing tools, etc., can solve the problems of complex control system, large input power and large power consumption of electromagnetic punching machines, and achieve the reduction of the overall volume and system Power consumption, the effect of low power consumption of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

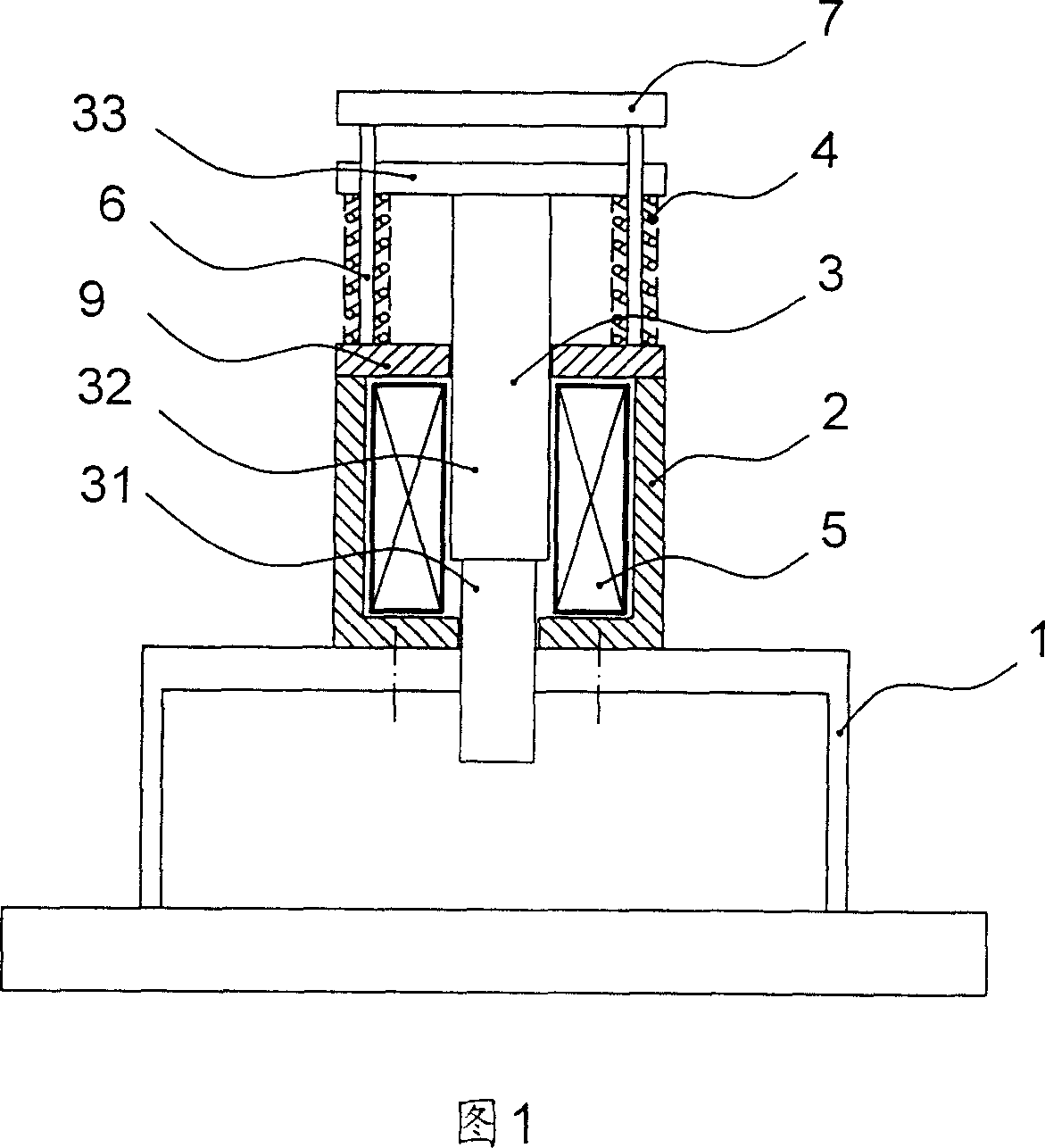

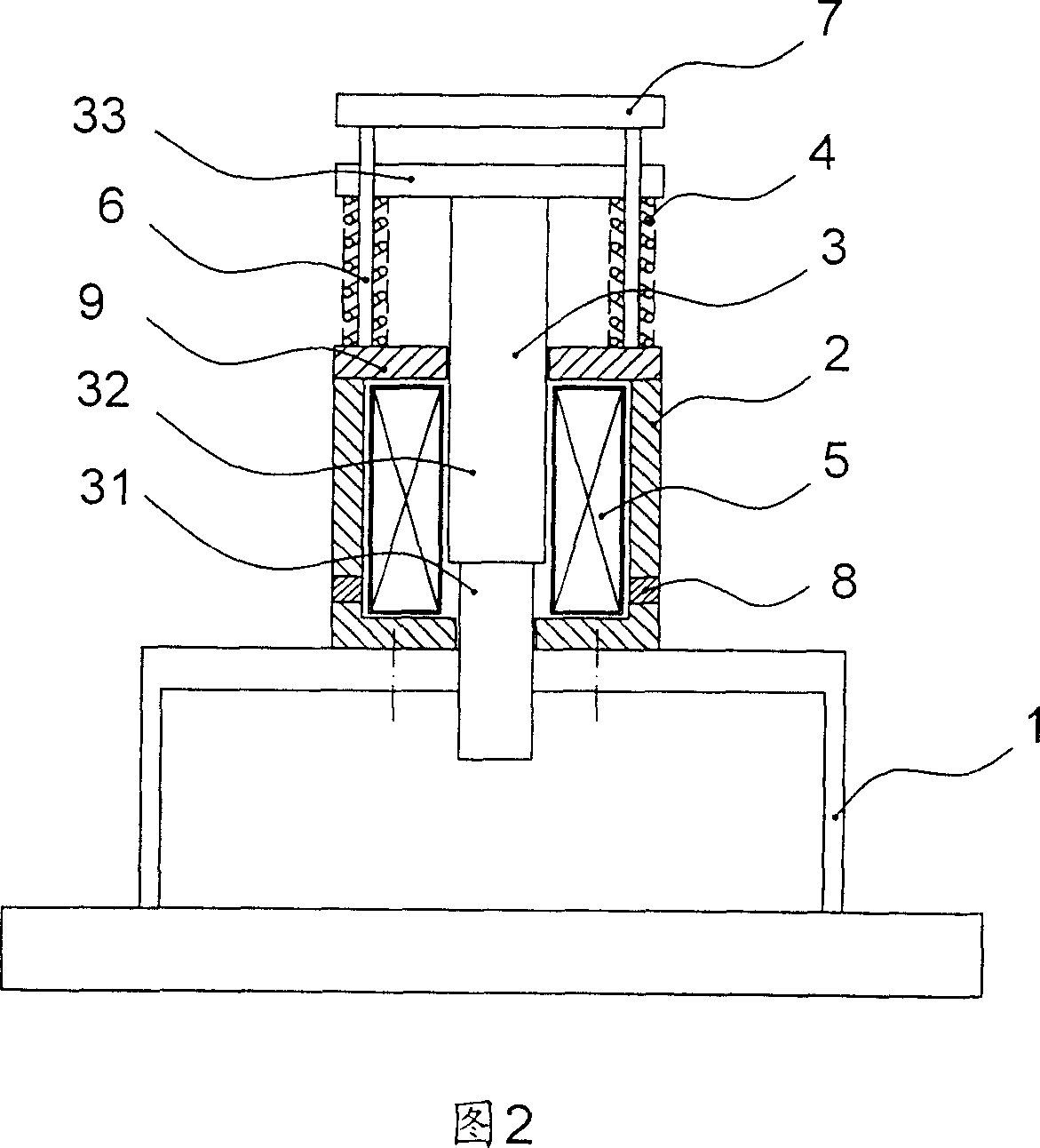

[0036] Fig. 2 is a schematic structural view of the permanent magnet punch press of the present invention. As shown in Figure 2, the permanent magnet punch press of the present invention includes a frame 1, a yoke 2, an end plate 9, a guide post 6 and a limit plate 7 connected in sequence, and also includes a punch spindle 3 that runs through the yoke 2, the The punch spindle 3 is composed of a punch 31 , an armature 32 and a guide sleeve plate 33 connected in sequence. The end plate 9, the bottom surface of the yoke 2 and the support 1 are all provided with through holes for the punch main shaft 3 to pass through. The electromagnetic coil 5 that generates the electromagnetic field is arranged in the annular space between the inner wall of the yoke 2 and the punch spindle 3, and the electromagnetic field generated by it generates an electroma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com