Metallurgical impact pad

A technology of impact pads and tundishes, which is applied in the field of impact pads and can solve complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

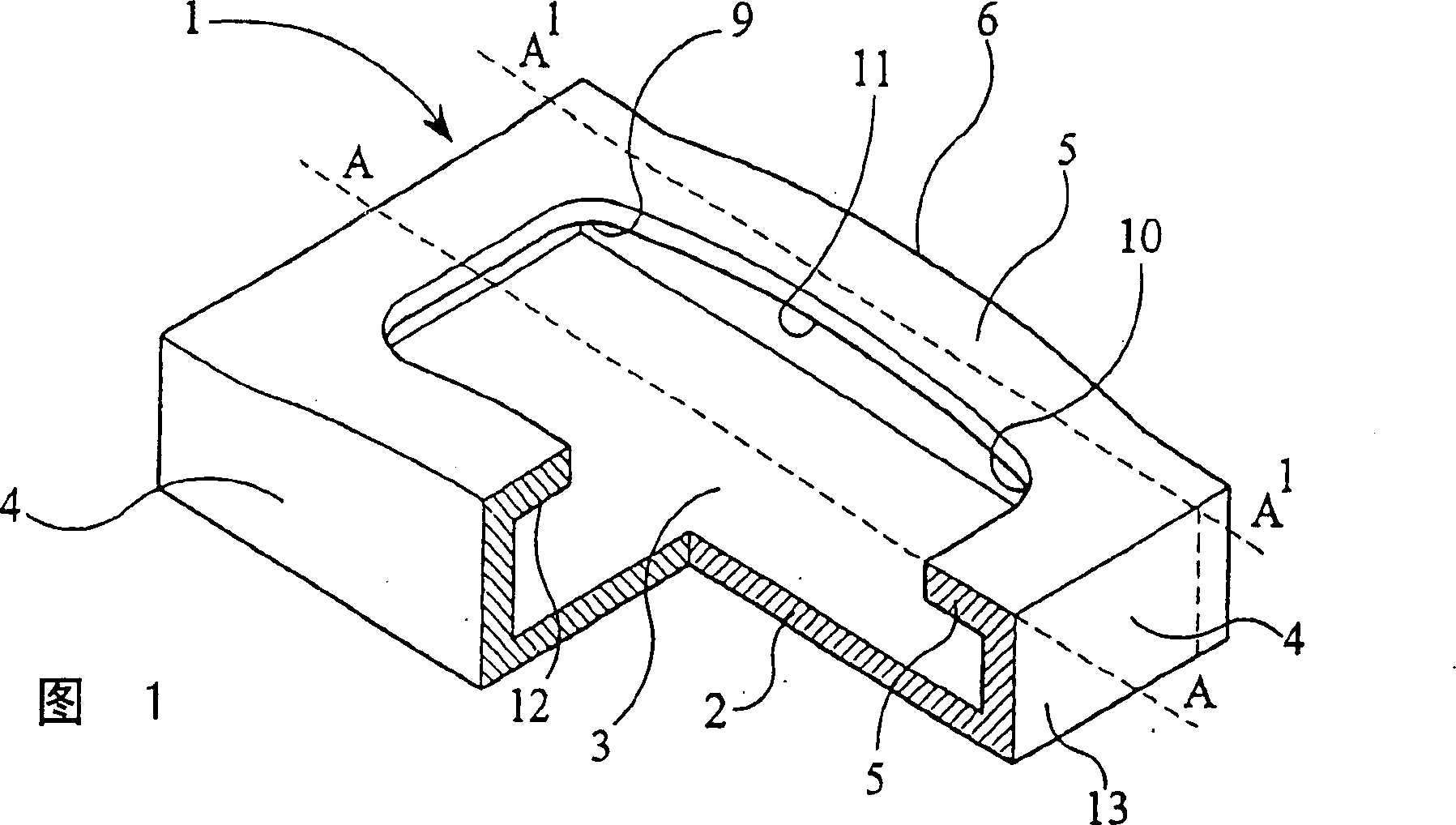

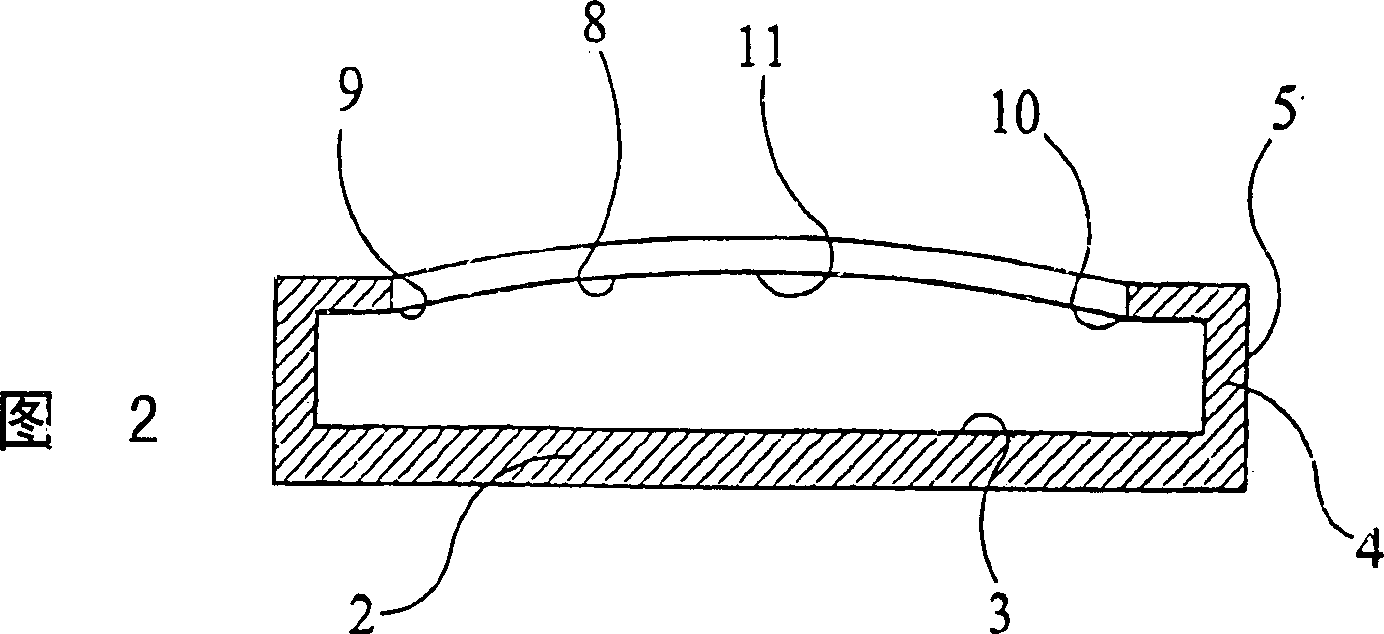

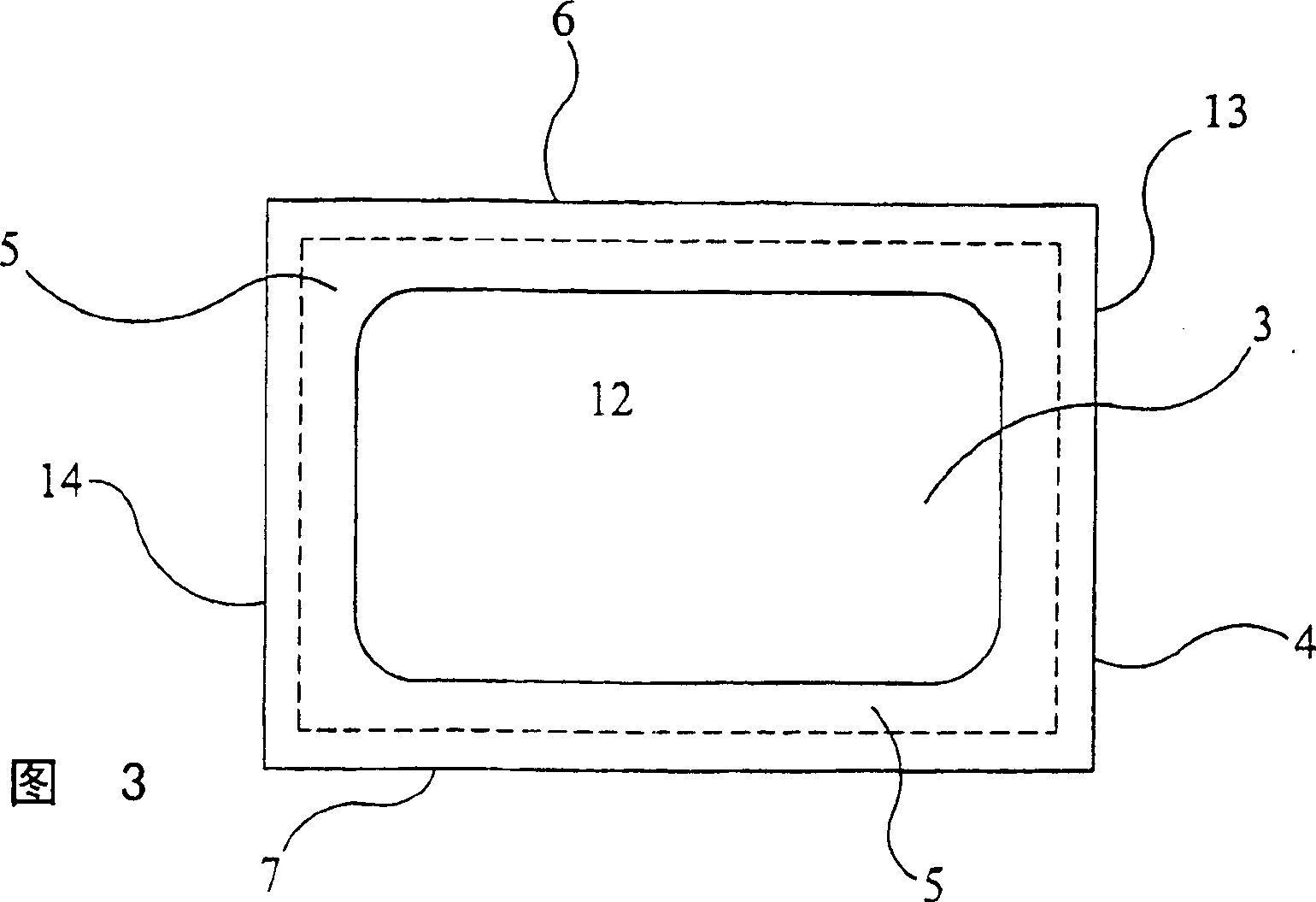

[0058] Figures 1 to 3 show an impact pad 1 comprising a base 2 having an impact surface 3, a wall 4 extending upwardly from the base 2 and an overhang 5 projecting inwardly from the wall 4 . Along the opposite parallel sides 6 and 7 of the impact pad, the lower surface 8 of the overhang 5 is arcuately curved. Referring to the side 6 of the impact pad 1, it can be seen that the vertical height of the overhang above the base plate increases gently, but not linearly, from a minimum at the end 9 to a maximum at the center 11 and back to The reference numeral 10 reduces again to a minimum value. Thus, the overhang forms an arched top over the perimeter of the floor. Side 7 has a similar arched portion 12 which is a mirror image of its symmetry on side 6 . The overhang portion 5 protruding from the opposite ends 13 , 14 of the impact pad has a generally uniform height above the base plate, ie the lower surface of the overhang is generally horizontal and parallel to the plane of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com