Zoom camera having lens barrel assembly adjustable focus and resolution power of lens

A camera, lens barrel technology, applied in the field of zoom cameras, can solve the problems of reduced productivity and increased working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

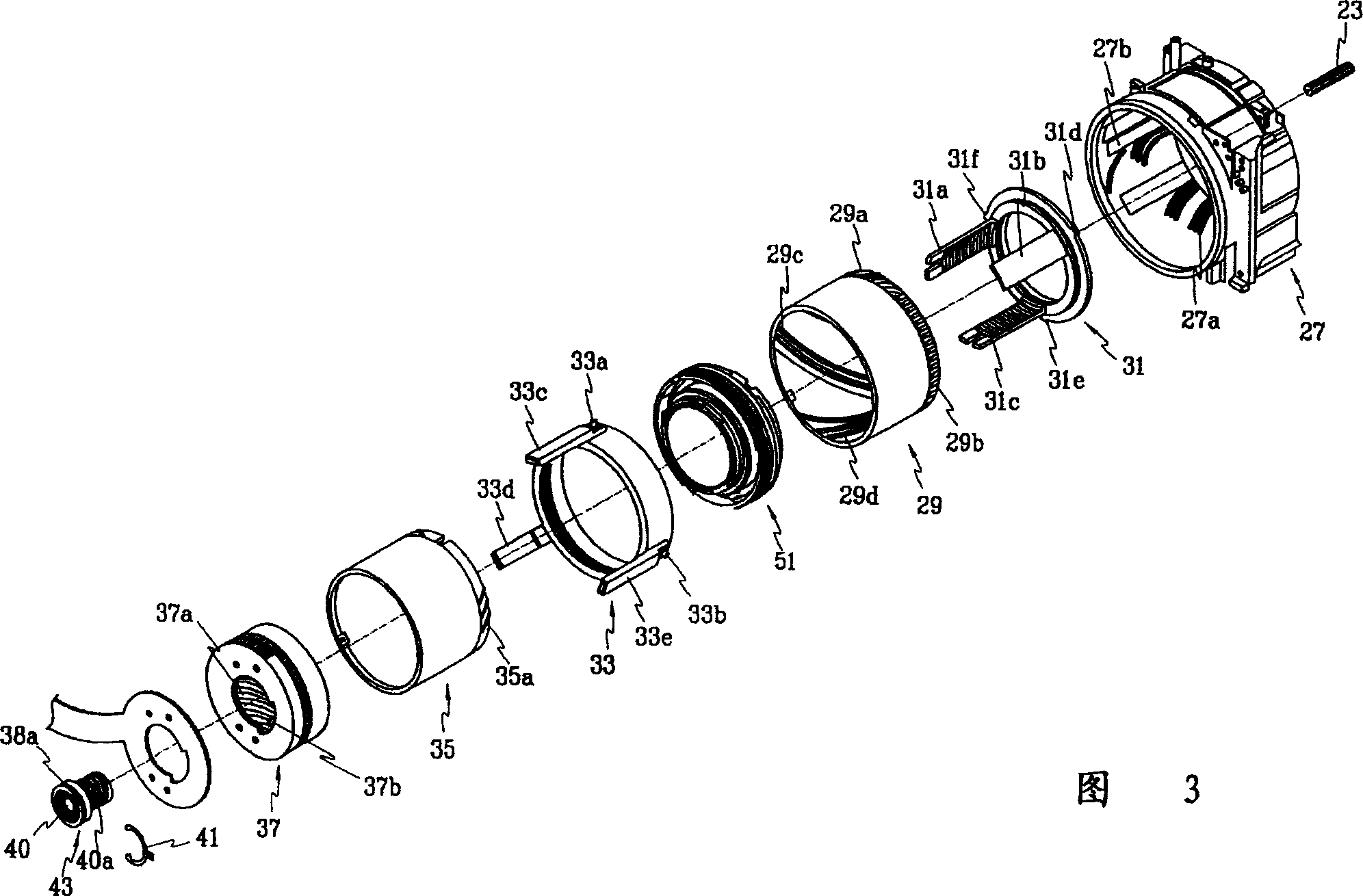

[0023] Reference will now be made in detail to the preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

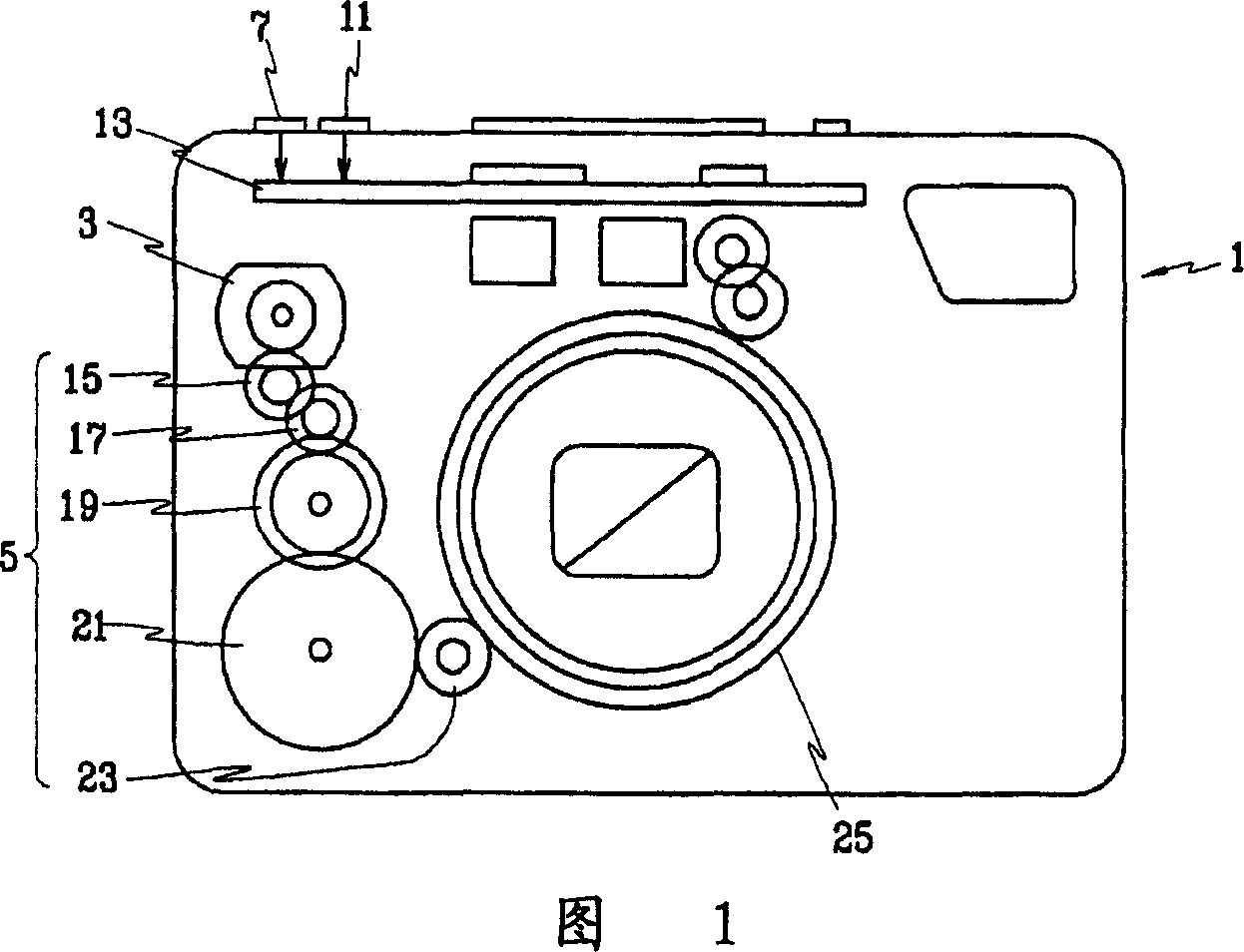

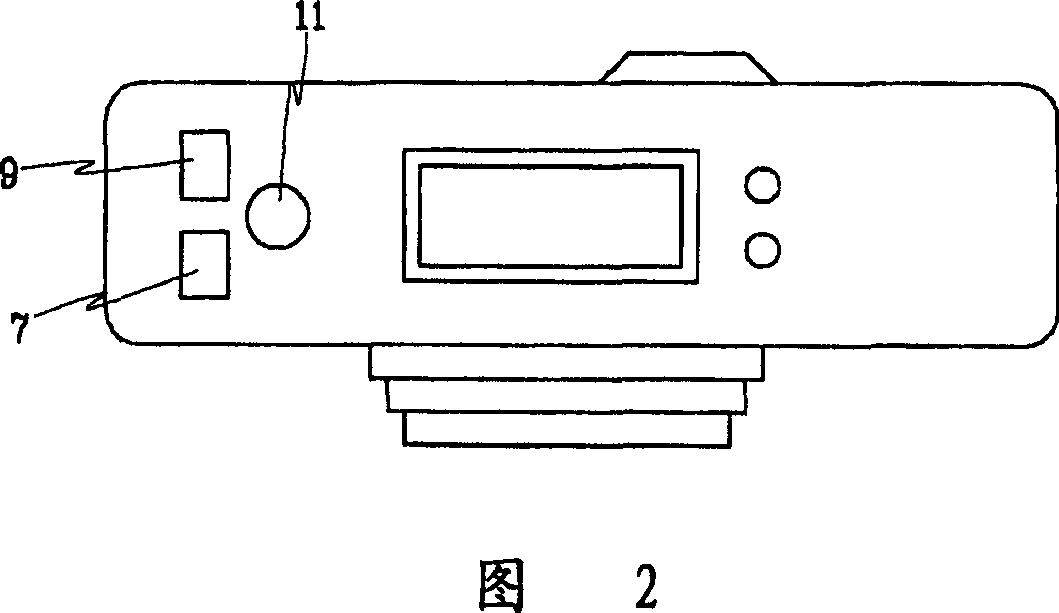

[0024] 1 and 2 show a camera according to a preferred embodiment of the invention.

[0025] As shown in the figure, the zoom camera includes a camera body 1, a zoom motor 3 as a zoom driving source, and a power transmission gear set 5 for decelerating a rotational force and transmitting the rotational force to a lens barrel.

[0026] A telephoto switch 7, a wide-angle switch 9 and a release switch 11 are arranged on the top surface of the camera body 1. The telephoto switch 7 and the wide-angle switch 9 are connected to a control circuit 13 accommodated in the camera body to drive the zoom motor 3 .

[0027] The zoom motor 3 is installed in the camera body 1 and is connected with the control circuit 13, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com