Electric transformer dynamic combined voltage regulating on-load voltage regulating method and apparatus

A technology of power transformer and voltage regulating winding, applied in the direction of transformer/inductor coil/winding/connection, etc., can solve the problems of affecting parallel operation, power grid overvoltage shock, complex structure, etc., to reduce the closing excitation inrush current, reduce the resistance Pressure requirements, the effect of simple control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

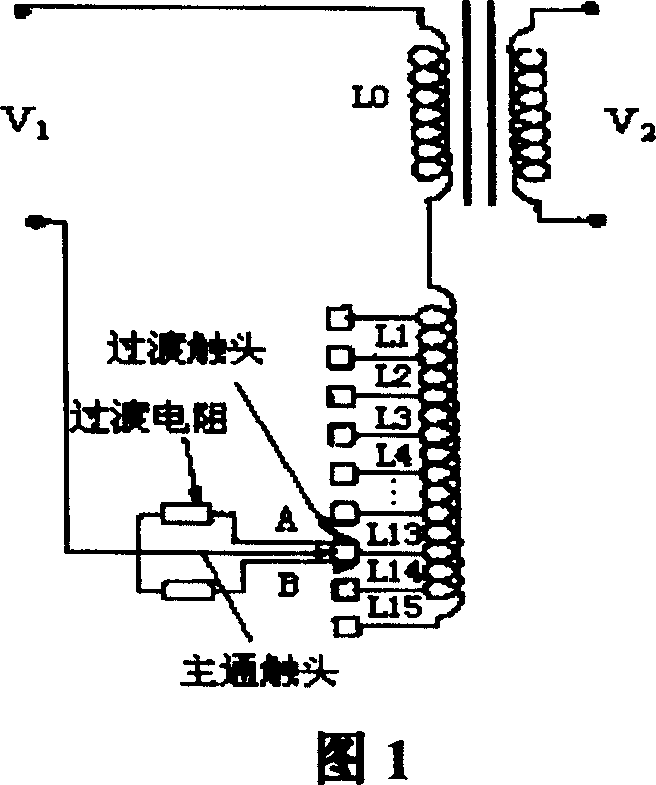

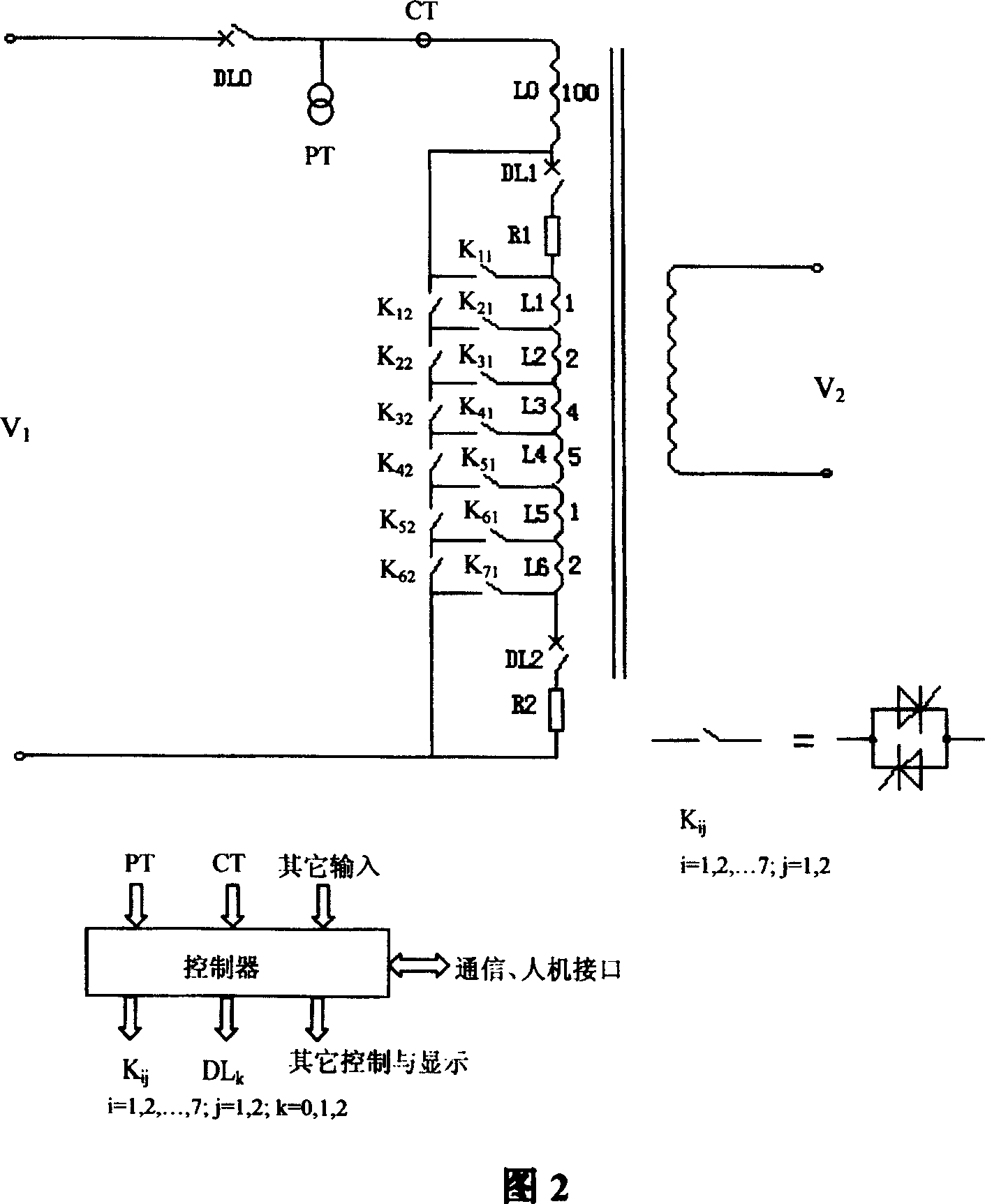

[0030] The working principle of the present invention will be further introduced in conjunction with accompanying drawing 2 below. Take the 15% voltage regulation range as an example.

[0031] In accompanying drawing 2, PT and CT represent voltage transformer and current transformer respectively. DL0, DL1, and DL2 represent the main circuit breaker and two auxiliary circuit breakers respectively. R1 and R2 represent current limiting resistors respectively. L1, L2, L3, L4, L5 and L6 represent six voltage regulating windings respectively. K11, K21, K31, K41, K51, K61 and K71 respectively represent 7 arm power electronic switches. K12, K22, K32, K42, K52 and K62 represent 6 bridge power electronic switches respectively.

[0032] The bridge arm type voltage regulating unit of the present invention can be represented by the voltage regulating winding L1 and K11, K21 and K12, or by the voltage regulating winding L2 and K21, K31 and K22.

[0033] The maximum number of voltage re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com