Interlayer signal transmission structure of microwave mixed printed circuit board

A transmission structure and signal layer technology, applied in the microwave field, can solve the problem of large standing wave coefficient of cross-layer transmission of microwave mixed plate signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

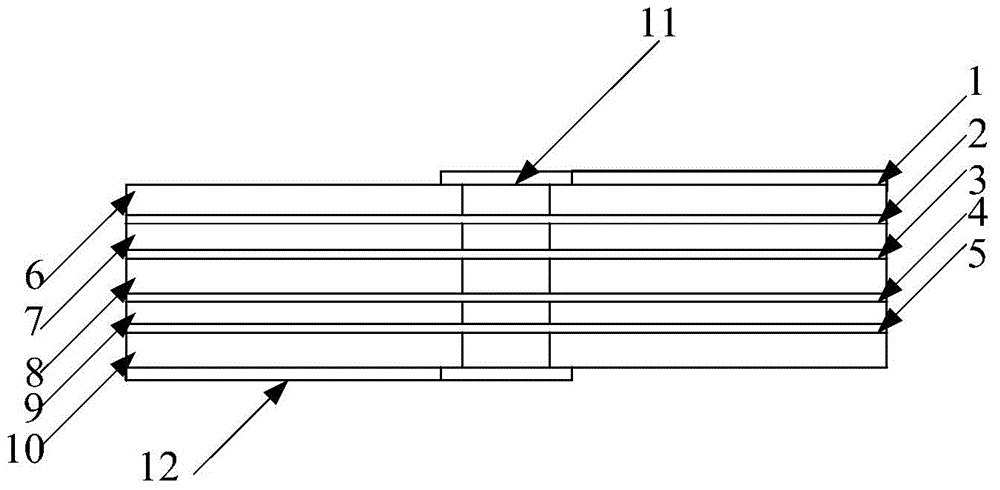

[0030] The printed circuit board design adopts the microwave mixed pressure multi-layer printed board process. Cascade structure such as figure 1 shown. This embodiment is a 6-layer board, 1 is the top signal transmission line (top layer), 2 is the top signal ground layer (second layer), 3 is the control layer (third layer), 4 is the power layer (fourth layer), 5 12 is the bottom signal transmission line (the sixth layer). The substrate used is: the material used for the first substrate 6 is Rogers4350B, and its dielectric constant ε r1 =3.66; the material used for the second substrate 7, the third substrate 8, the fourth substrate 9 and the fifth substrate 10 is TU662, and its dielectric constant ε r2 = 3.8.

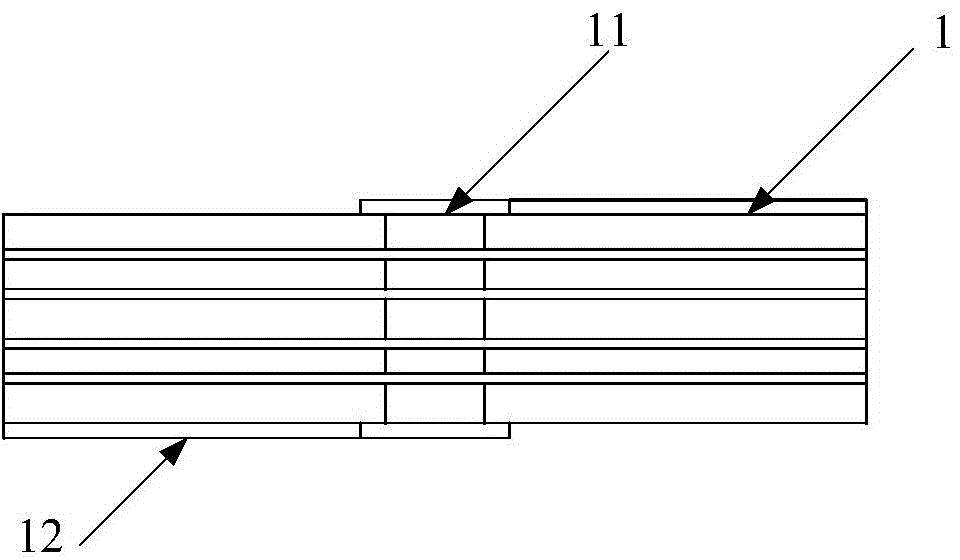

[0031] Such as Figure 5 , 6 shown. 11 is a through hole connecting the top layer and the bottom layer, and 13 is three ground holes for building a coaxial structure, and the ground holes run through the top layer to the bottom layer. 1 is a signal transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com