Radiating fan structure

A heat dissipation fan and heat sink technology, applied in the field of heat dissipation fans, can solve the problems of air flow loss, difficult heat dissipation efficiency, and the inability of cooling air flow to flow into the heat sink 20 smoothly, so as to slow down the rapid loss, prolong the time of heat exchange, and improve the overall The effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

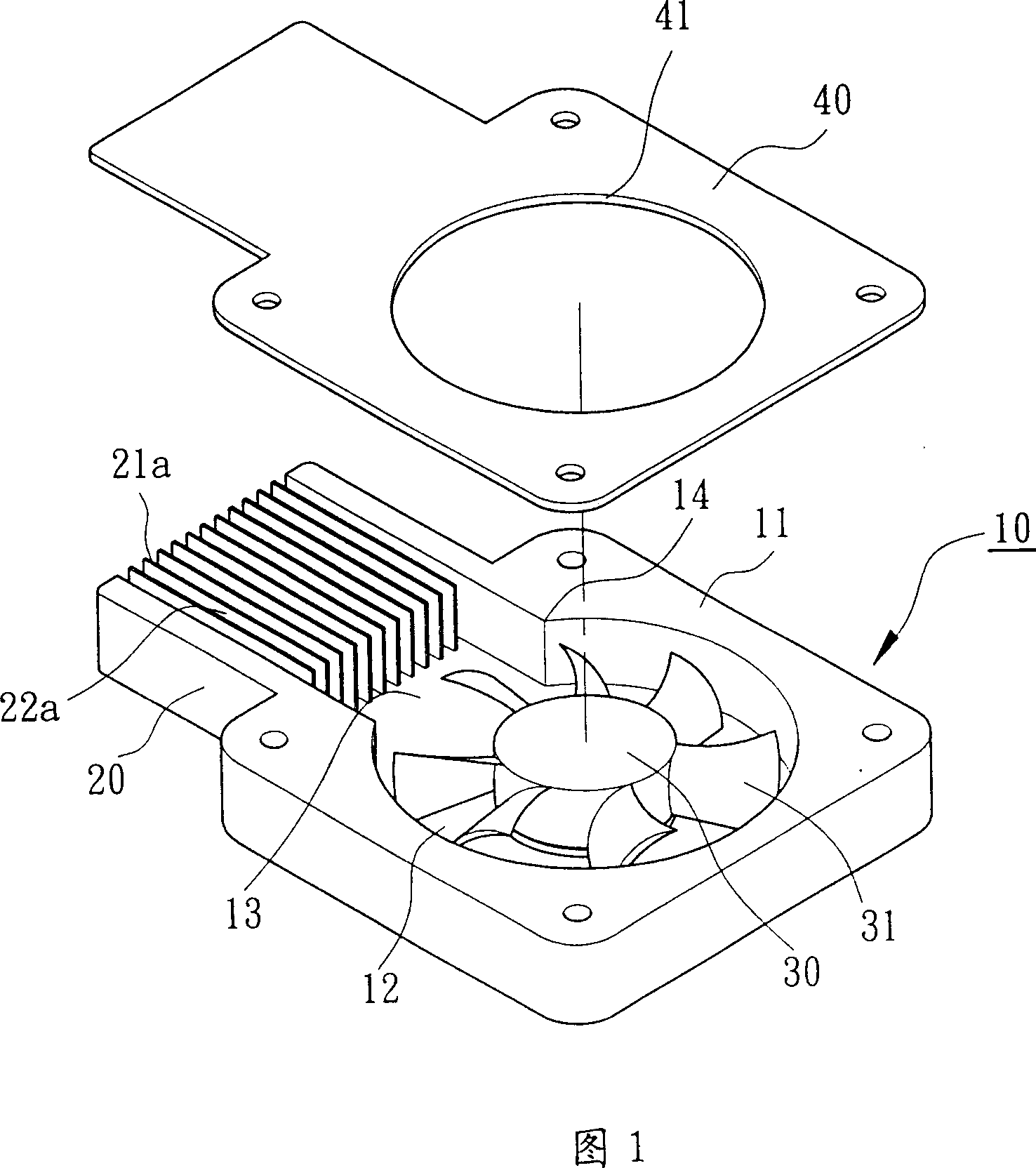

[0018] Part of the structure of the heat dissipation fan in the present invention is the same as that of the traditional heat dissipation fan shown in Figure 1, and the parts with the same structure are shown with the same label, for this reason, in the following embodiments, for the parts with the same label The specific structure and function will not be described in detail again.

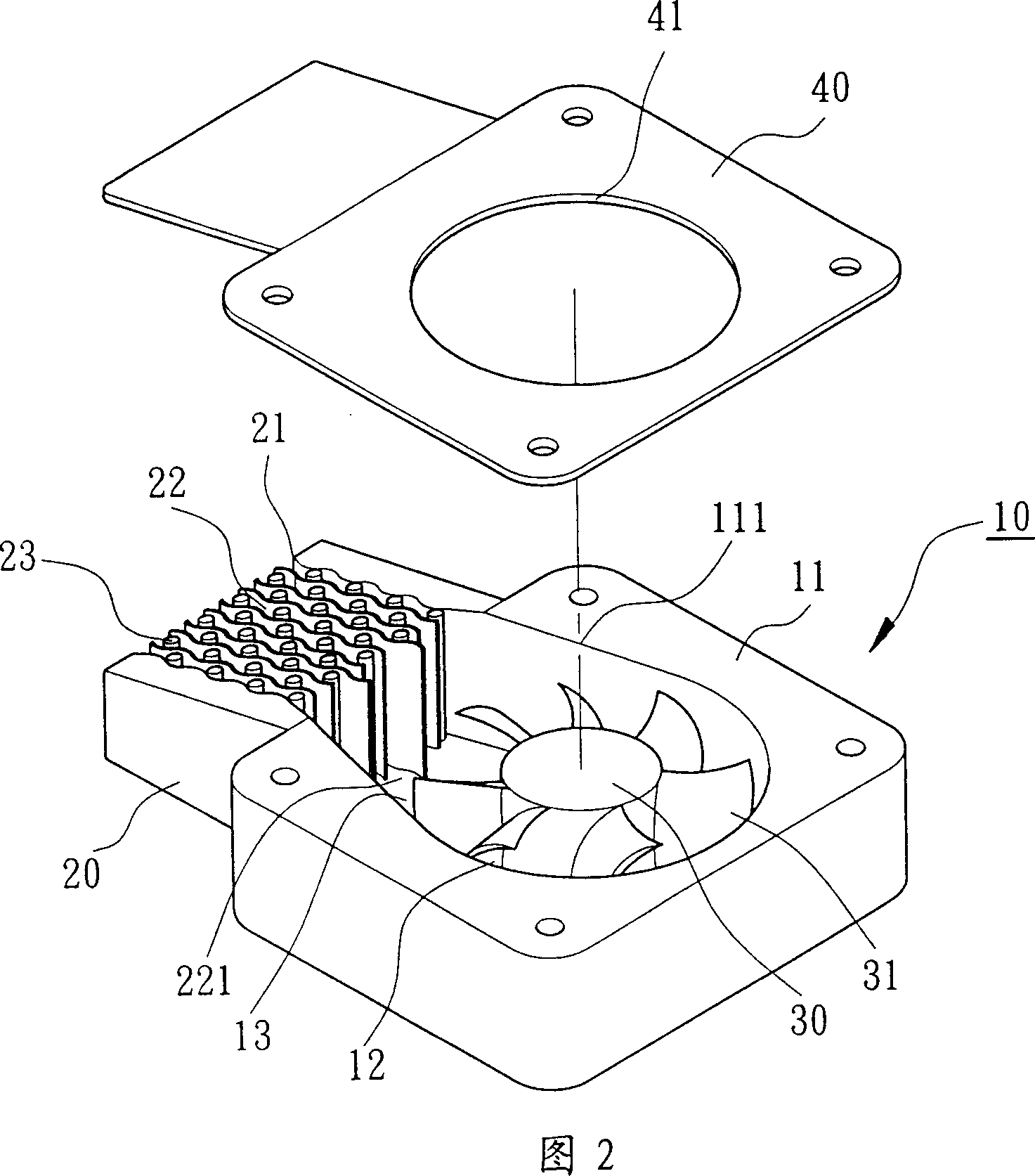

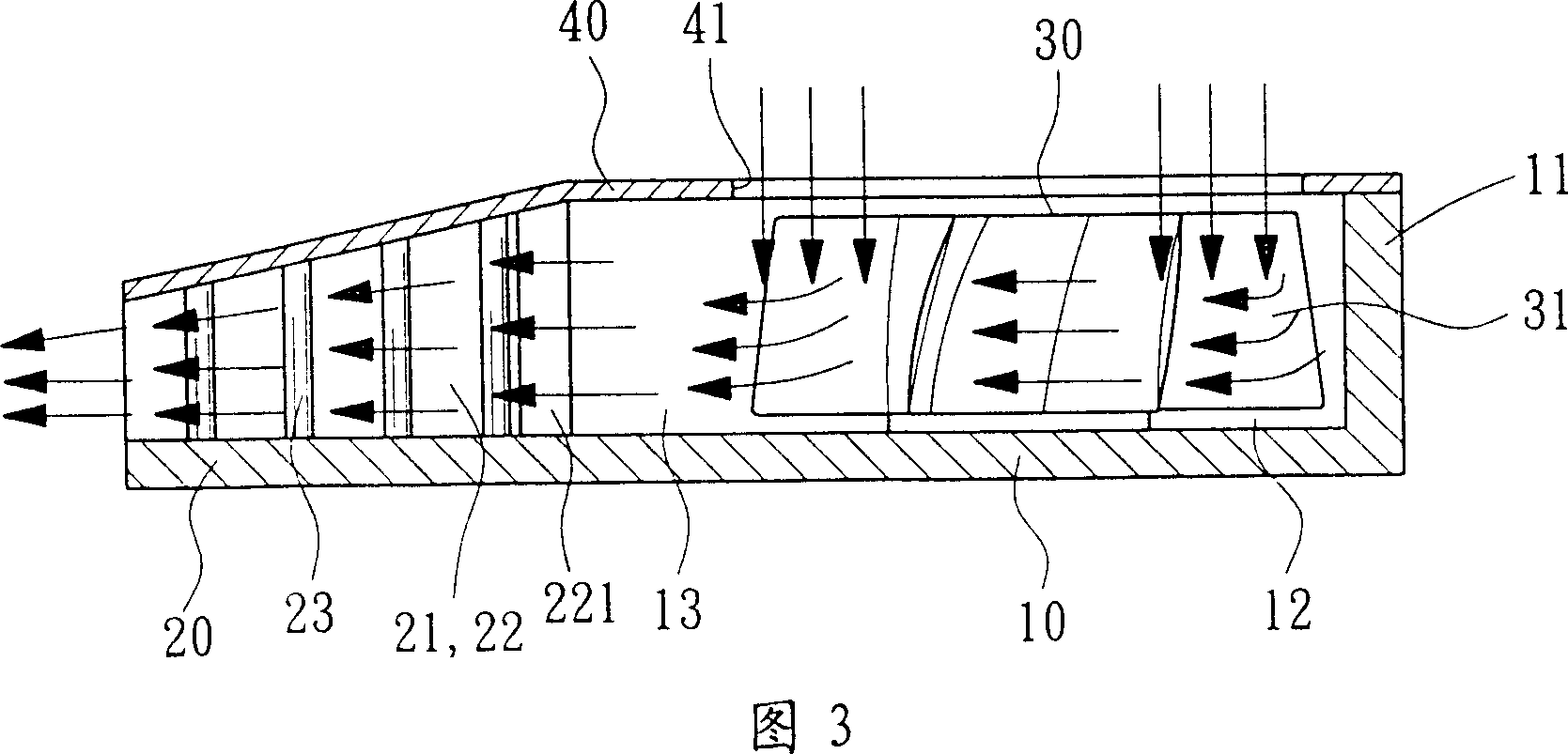

[0019] As shown in FIGS. 2 and 3 , the cooling fan structure in the first embodiment of the present invention includes a fan casing 10 , a cooling fin 20 , a fan wheel 30 and an upper cover 40 . The fan housing 10 is provided with several side walls 11, a chamber 12 and at least one air outlet 13; the cooling fin 20 is arranged outside the air outlet 13 of the fan housing 10; the fan wheel 30 is located in the chamber 12, and has several a blade 31 ; the upper cover 40 is set on the top of the fan housing 10 and the heat sink 20 , and is provided with an air inlet 41 .

[0020] As shown in Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com