Auxiliary anode electrolysis milling processing system and method

An auxiliary anode and processing system technology, applied in the field of auxiliary anode electrolytic grinding and milling processing system, can solve problems such as unstable processing, cavitation phenomenon, inconsistent electrolytic removal speed, etc., to improve processing stability, avoid liquid shortage, Effect of Suppressing Stray Corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

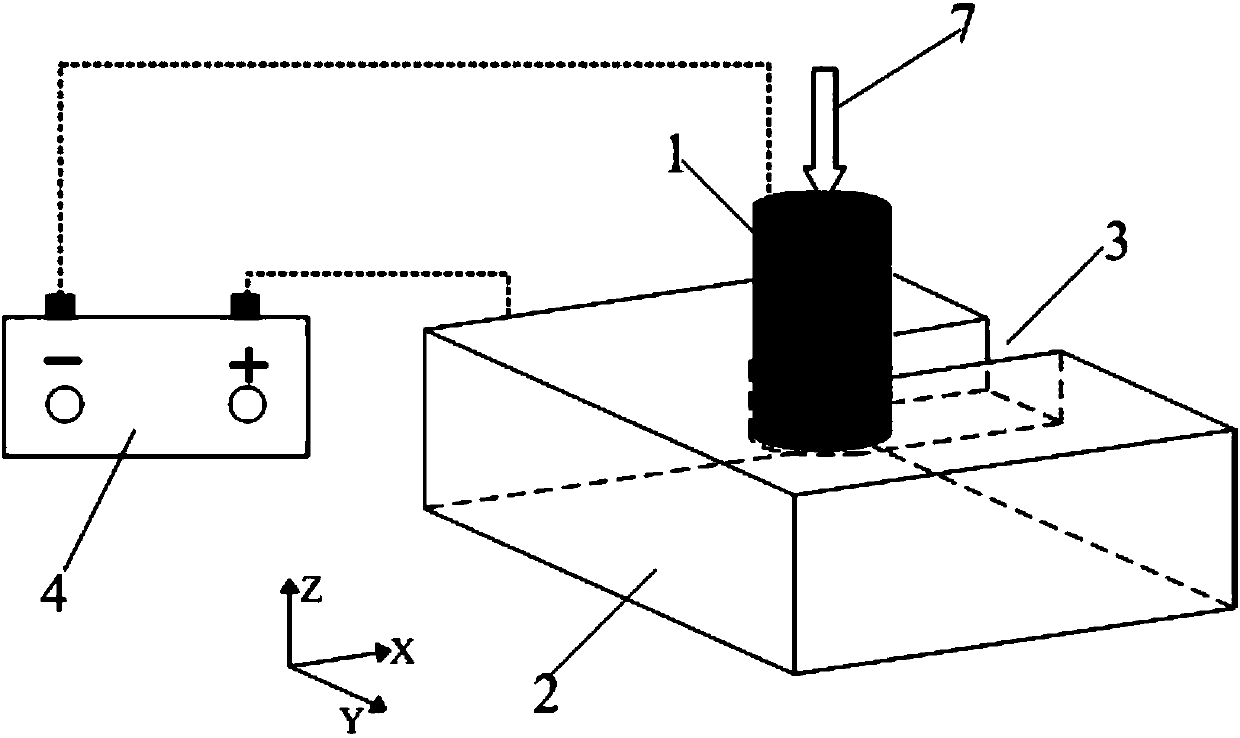

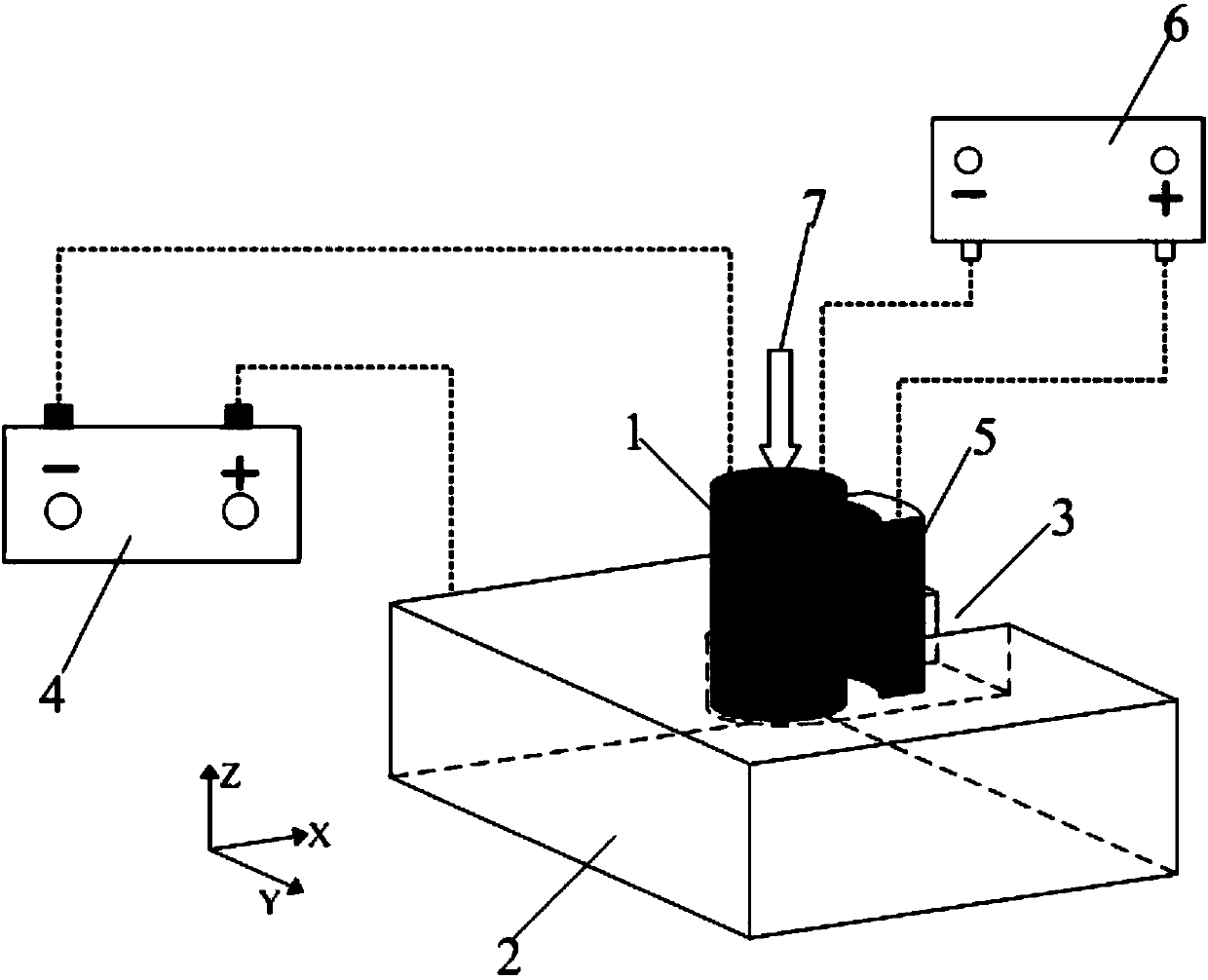

[0036] combine figure 2 , illustrate the processing method concrete implementation process that the present invention proposes:

[0037] Step 1. Clamp and position the tool cathode 1, workpiece 2 and auxiliary anode 5 respectively;

[0038] Step 2, connect the positive pole of the main power supply 4 to the workpiece 2, connect the negative pole to the tool cathode 1, and adjust the working parameters of the main power supply 4;

[0039] Step 3. Connect the positive pole of the auxiliary power supply 6 to the auxiliary anode 5, and connect the negative pole to the tool cathode 1, and adjust the working parameters of the auxiliary power supply 6;

[0040] Step 4. Pass the electrolyte solution along the direction 7, and reach the processing area (3) through the liquid hole of the tool cathode (1);

[0041] Step 5, turn on the main power supply 4 and the auxiliary power supply 6, and then start the electrolytic milling process;

[0042] Step 6. Stop processing and retract the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com