Additive manufacturing smelting equipment

A smelting equipment and additive manufacturing technology, applied in the field of additive manufacturing, can solve the problems of thermal fatigue effect of surrounding components, reduce component safety, heat dissipation, etc. drain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

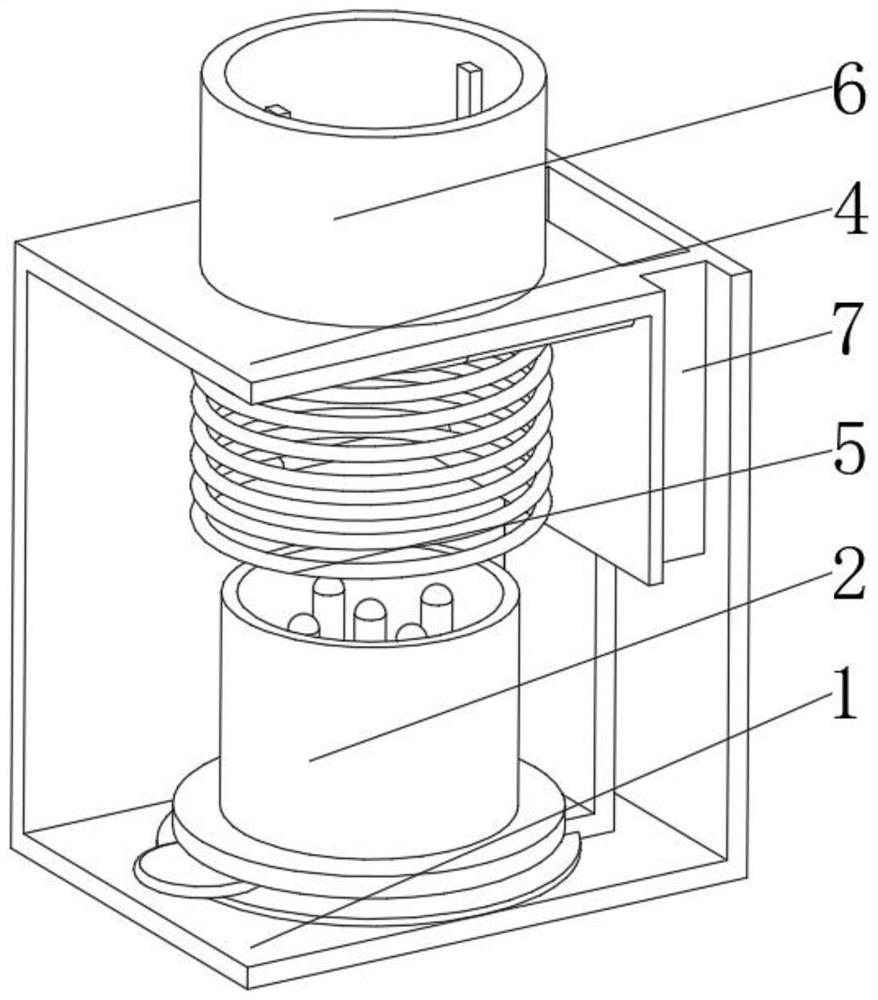

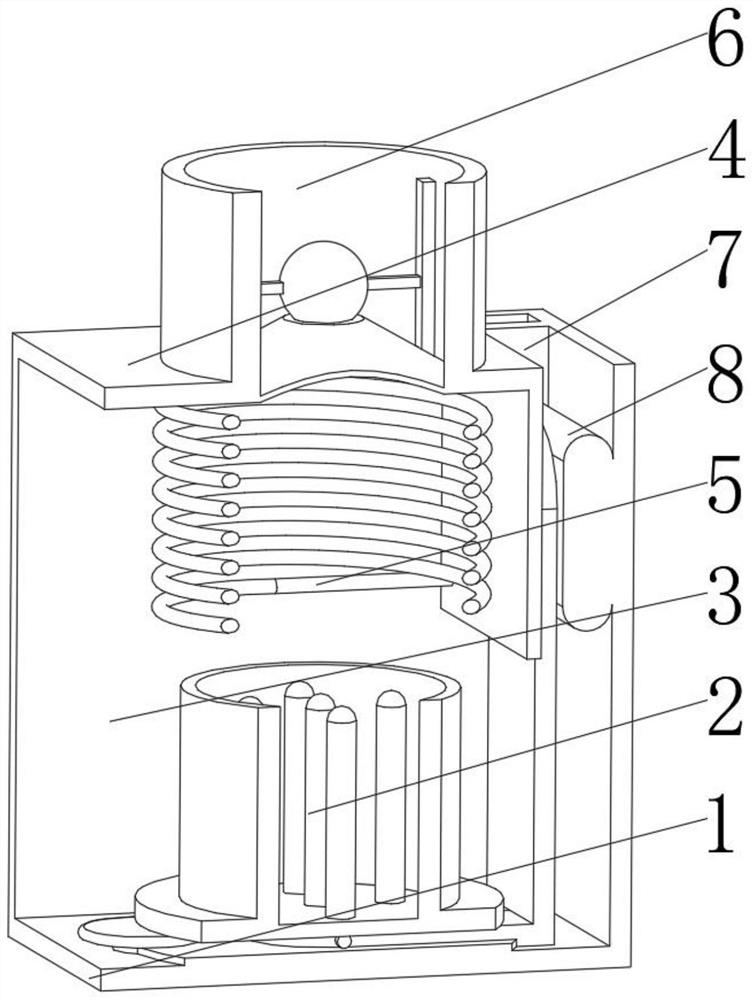

[0038] see Figure 1-3 , the present invention provides a technical solution: a smelting equipment for additive manufacturing, specifically comprising:

[0039] Bottom box seat 1, the bottom box seat 1 has a square seat plate, and a smelting device 2 installed in the middle of the top of the square seat plate, and an L-shaped baffle plate 3 installed on the top of the square seat plate and at the back of the smelting device 2, and The protective top plate 4 installed on the top of the L-shaped baffle 3, and the high-frequency coil 5 installed at the bottom of the protective top plate 4, and the smoke device 6 installed on the top of the protective top plate 4, and installed on the rail limit on the right side of the protective top plate 4 plate 7, and a lifter 8 installed on the inner wall of the L-shaped baffle plate 3 and located in the cavity of the track limiting plate 7. Through the setting of the high-frequency coil 5, the high-frequency eddy current heating is carried ...

Embodiment 2

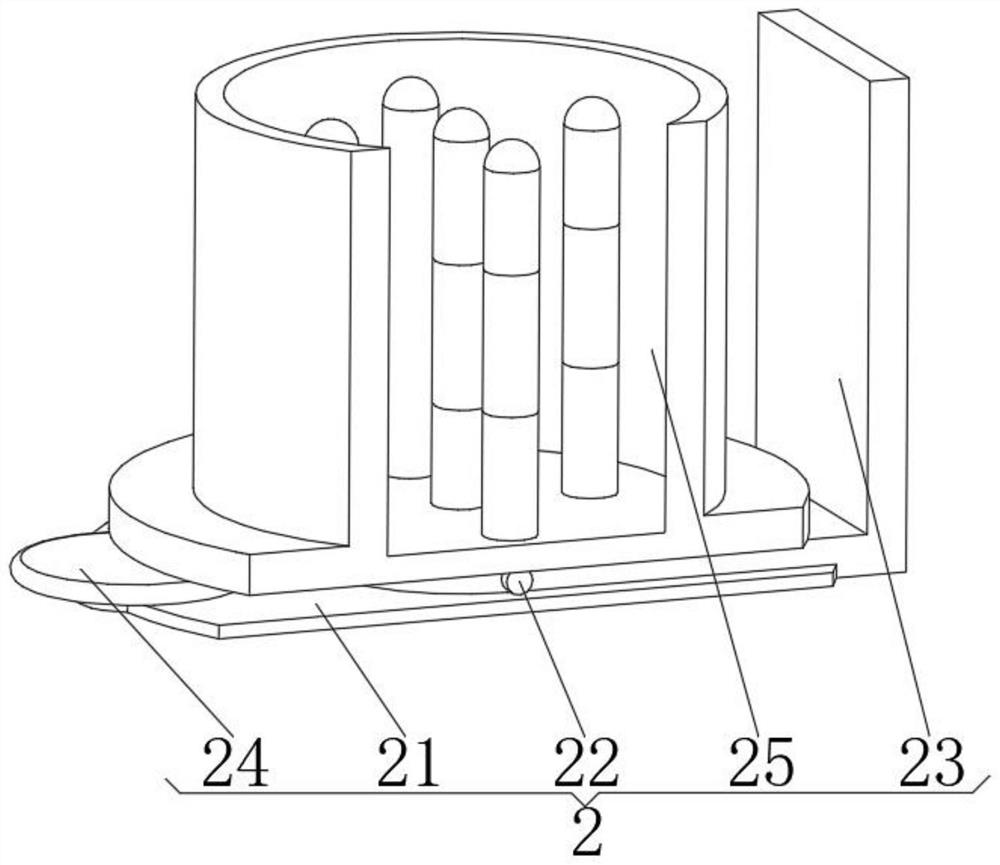

[0048] see Figure 1-5 , on the basis of Embodiment 1, the present invention provides a kind of technical scheme: melting device 25 comprises:

[0049] Turntable base 251, the turntable base 251 has a circular base plate, a built-in device 252 installed in the middle of the top of the circular base plate, and a bearing box 253 installed on the top of the circular base plate and outside the built-in device 252. Through the design of the turntable base 251, the area of the base is increased, the relative height of its own center of gravity is reduced, the stability performance is improved, and the leakage of the internal additive manufacturing raw materials caused by the inclination of the melting device 25 itself during the melting process is avoided, and the surrounding components are protected.

[0050] Built-in devices 252 include:

[0051] Seat column 2521, the seat column 2521 has a cylindrical body, and a heat generating column 2522 installed in the middle of the top o...

Embodiment 3

[0054] see Figure 1-6 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the flue gas device 6 includes:

[0055] A flue gas cylinder 61, the flue gas cylinder 61 has a cylindrical cylinder, a conical frustum cylinder 62 installed on the inner surface of the cylindrical cylinder, a rotating frame 63 installed on the top of the conical frustum cylinder 62, and a rotating frame 63 installed on the rotating frame 63 close to each other Side auxiliary rod 64, and the closed ball 65 that is installed on the side of auxiliary rod 64 away from rotating frame 63. Through the design of the closed ball 65 and the oblique diversion lines engraved on the surface of the closed ball 65, the component seals the melting device 25 to reduce the rapid loss of heat. At the same time, the closed ball 65 is rotated by the oblique guide lines to slow down the flow of the flue gas and reduce its flow speed, which facilitates the precipitation and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com