Superficial character fine Fe-Ni kind camouflage plate

A technology with excellent surface properties, applied in the field of Fe-Ni shadow mask materials, can solve the problems of increasing the total amount of oxides, surface properties or etching and perforation are not necessarily sufficient, and achieve the effect of improving pixel quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

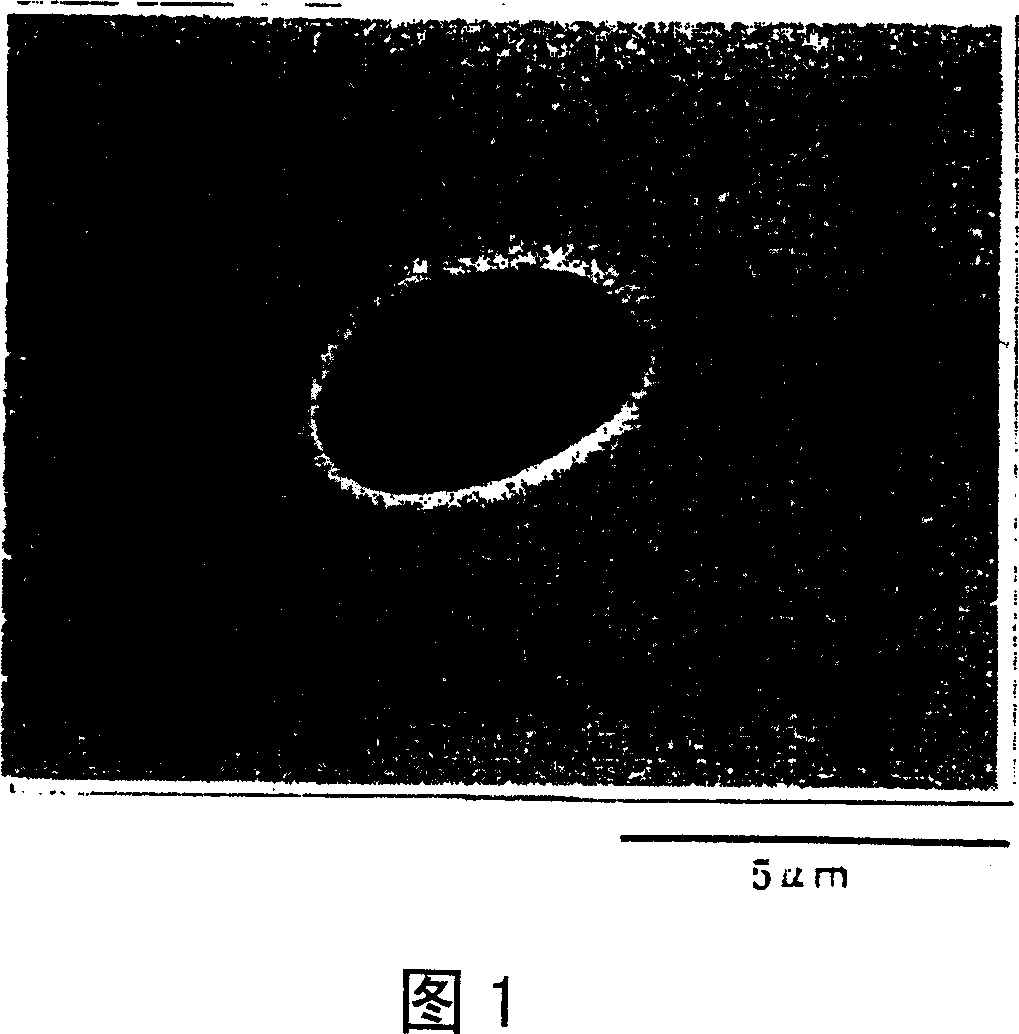

Image

Examples

Embodiment

[0044] Alloy ingots having the composition shown in Table 1 were produced by applying a generally performed refining process using an Al deoxidizer. In addition, Sample Nos. 1 to 6 are materials of the present invention to which addition of Mg was applied in the deoxidation step. Sample Nos. 7 to 8 are conventional materials.

[0045] No.

[0046] * The remainder contains unavoidable impurities

[0047] As can be seen from Table 1, the addition of Mg, which is a strong deoxidizing element, makes the oxygen content of the material of the present invention more stable and lower than that of the conventional material. This shows that the addition of Mg reduces the total amount of oxides that are detrimental to the surface properties and etched porosity, thereby bringing about these quality improvement effects.

[0048] Then, hot forging and hot rolling were performed on these alloy ingots to obtain a 2.5 mm thick cold rolling steel strip. Thereafter, 50 g of samples...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com