Air spring vibration isolation foundation with electromechanical damper

An electromagnetic damper and air spring technology, which is applied in non-rotational vibration suppression, building components, shockproof, etc., can solve the problems of long transition process, insignificant effect of hydraulic damper, and restricting the performance of vibration isolation system, etc. Process time improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

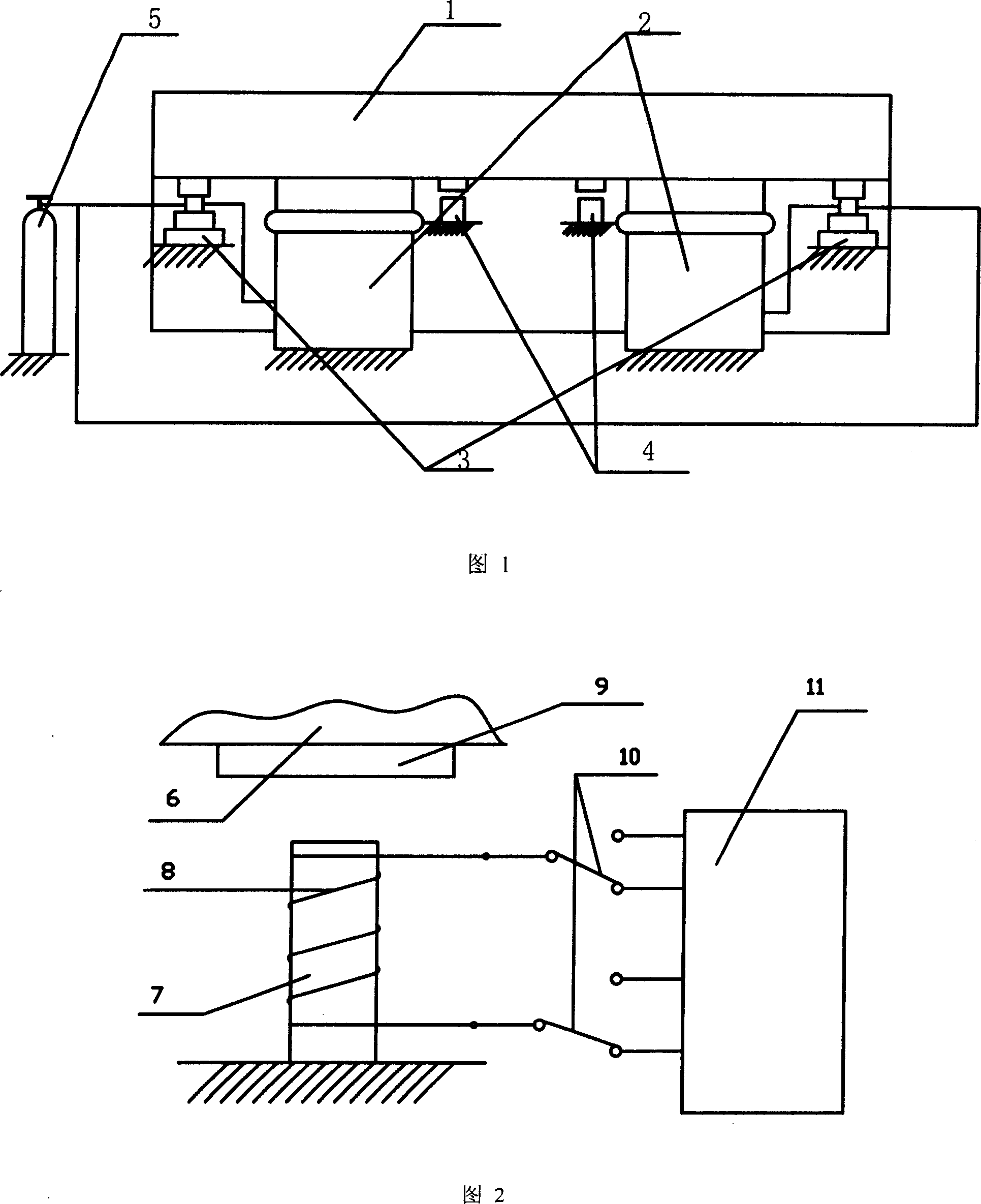

[0044] As shown in Figure 2, it is an embodiment of an air spring vibration isolation foundation with an electromagnetic damper, which is characterized in that the electromagnetic damper consists of an iron core 7, a coil 6, an armature 9, a reversing switch 10 and a controller 11 composition;

Embodiment 2

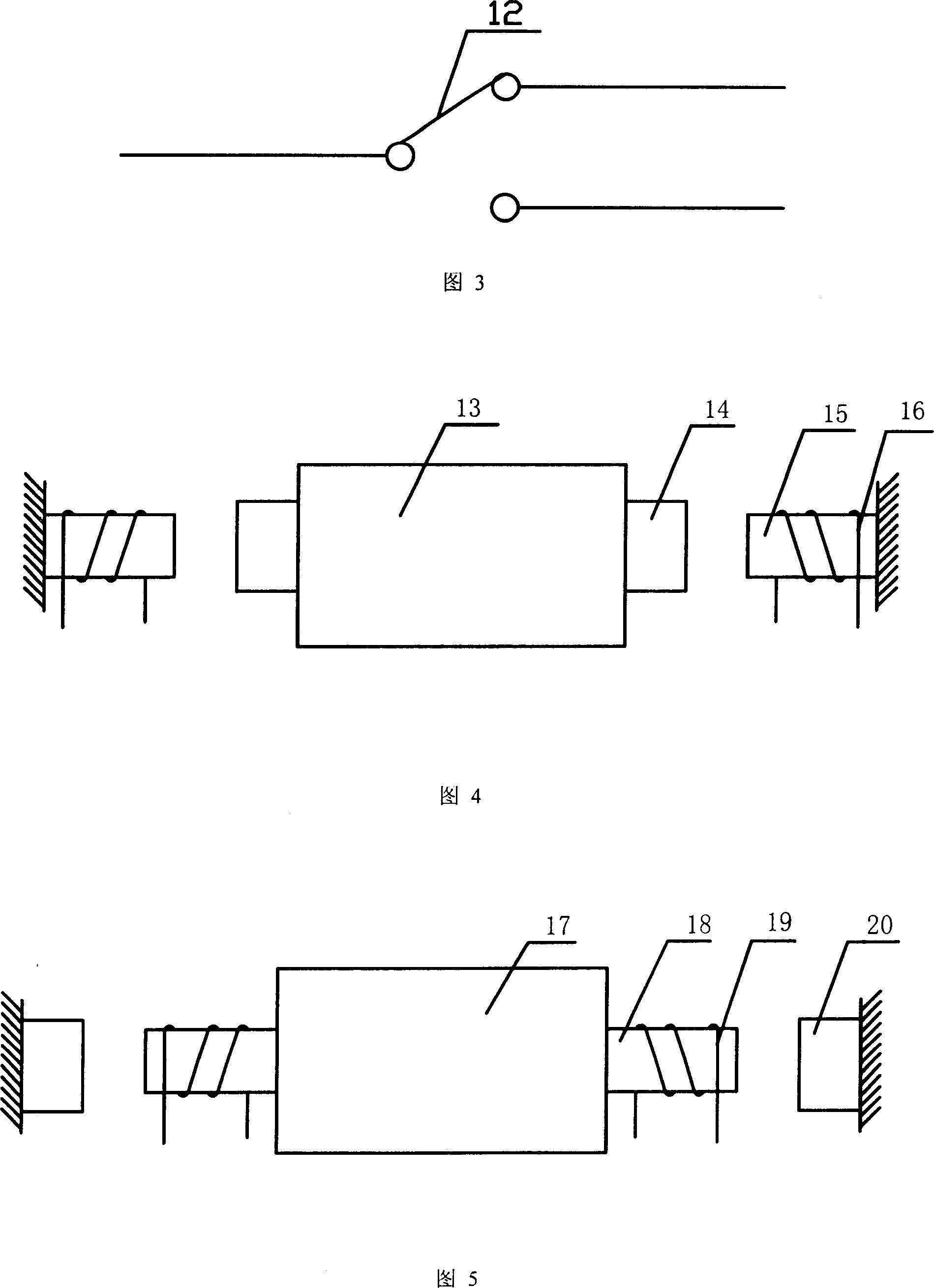

[0046] As shown in Figure 4, it is an embodiment of an air spring vibration-isolation foundation with an electromagnetic damper, which is characterized in that the iron core 18 is connected to the base body 17, and the armature 20 is connected to the ground;

Embodiment 3

[0048] As shown in Figure 4, it is an embodiment of an air spring vibration isolation foundation with an electromagnetic damper, which is characterized in that the iron core 15 is connected to the ground, and the armature 14 is connected to the base 13;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com