Glass bonded fiber array and method for the fabrication thereof

A fiber and glass technology, used in bundles of optical fibers, instruments, optical components, etc., can solve problems such as damage to the connection between optical fibers and supporting elements, unacceptable long processing time, and cracking of bonding materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

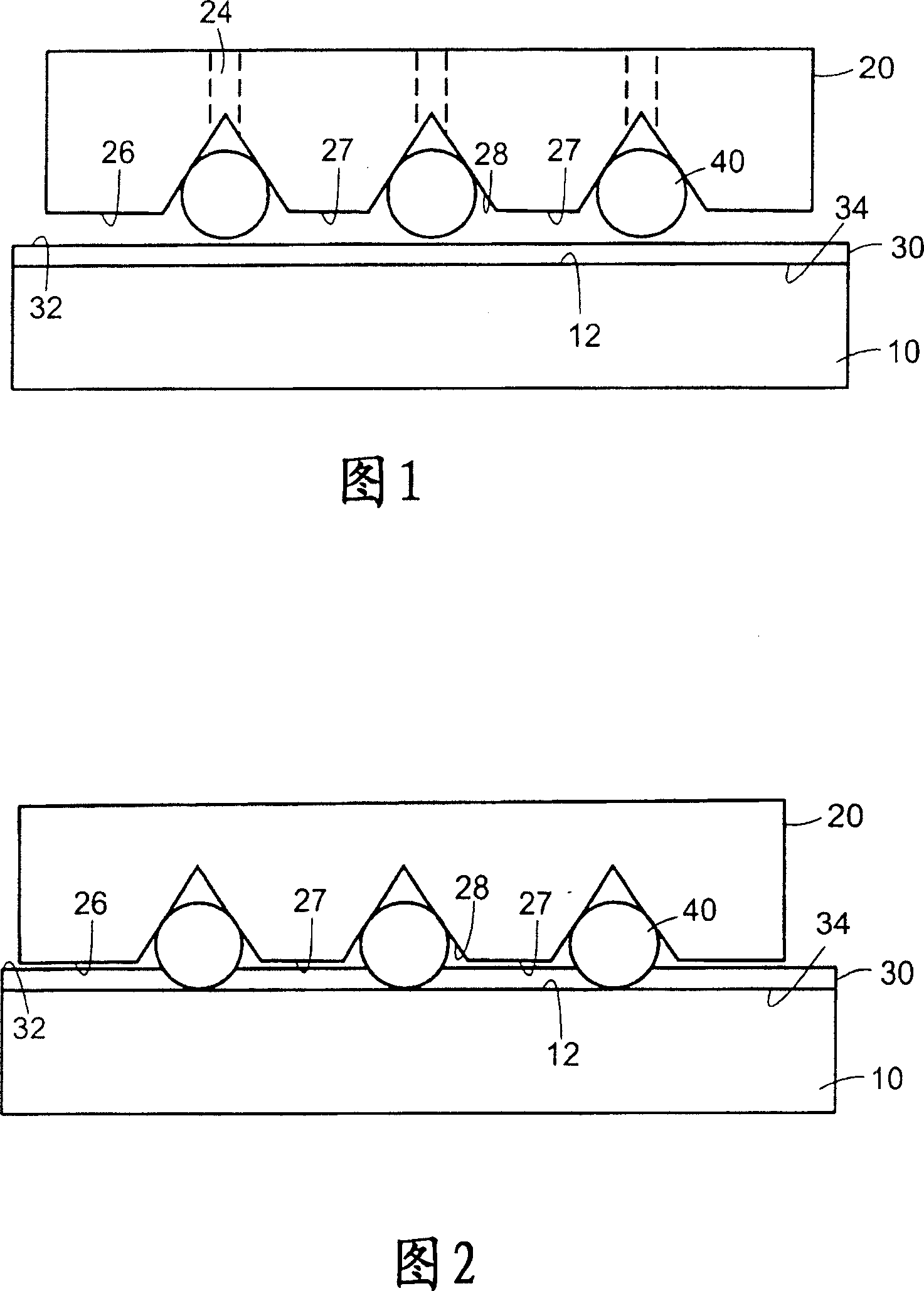

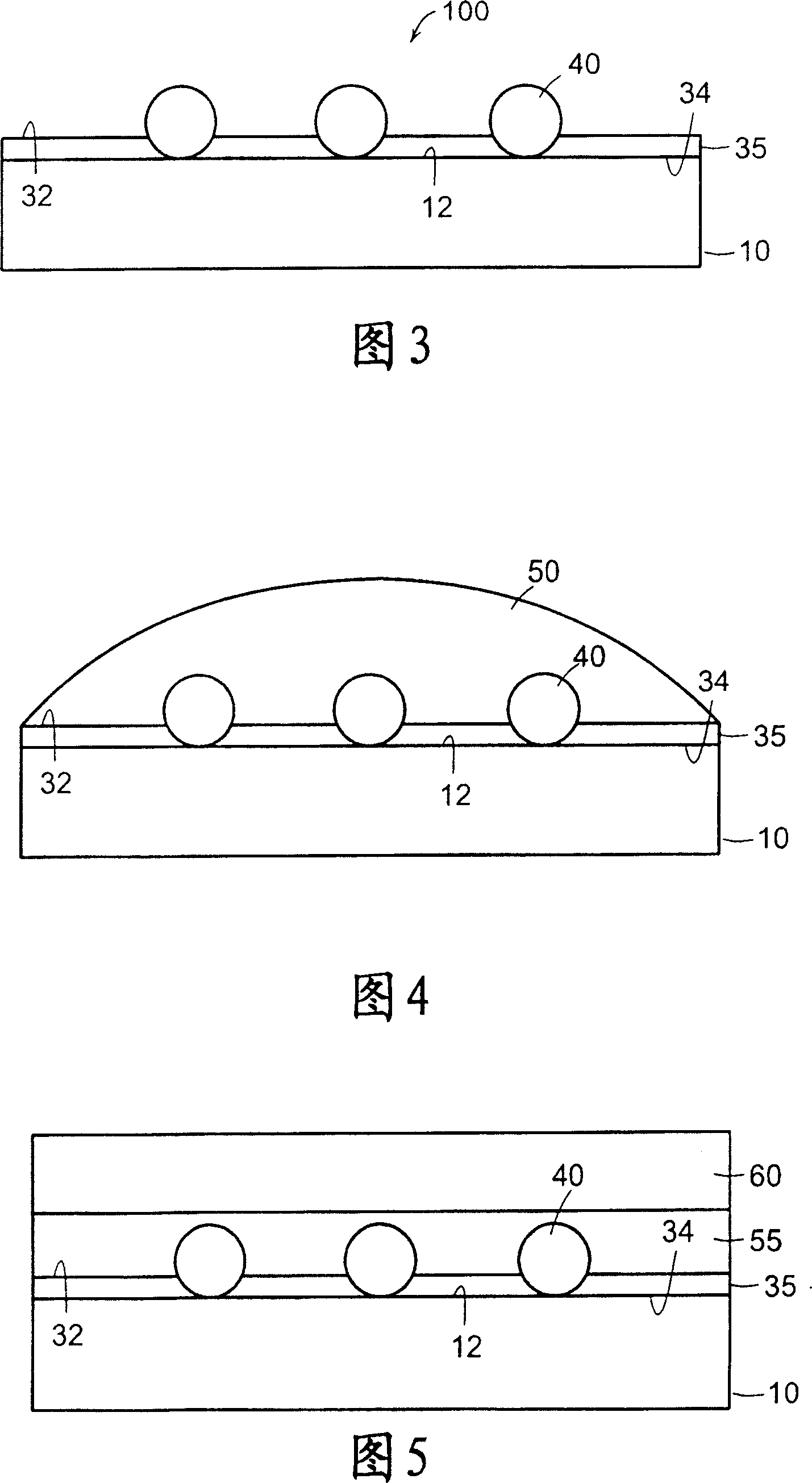

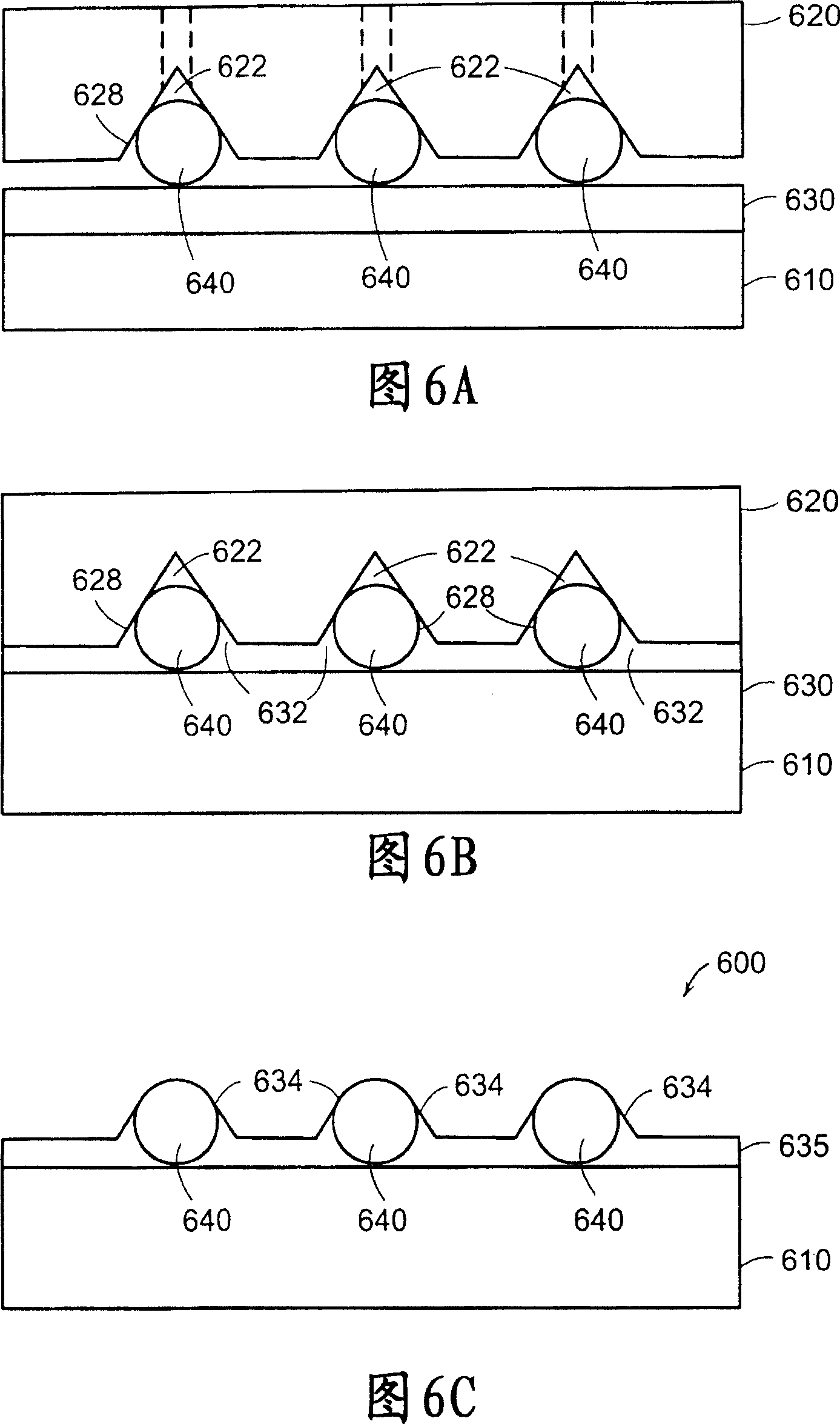

[0027] The present invention relates to precise installation between an optical fiber and a supporting element so that the fiber core relative to the selected position of the supporting element is safely and permanently connected to the supporting element at a precisely designated position, thereby providing an optical fiber bundle. Providing precise placement of the fiber core relative to the support element is critical to the ability of the fiber core to align with other optical elements when the fiber bundle is used in combination with other system components. Generally, an optical fiber has a central optical core surrounded by a cladding, which is covered by a buffer and a jacket. The precise placement of the fiber core relative to the support element is provided by aligning the buffer-free, unjacketed optical fiber portion with respect to the reference surface of the support element. A vitreous bonding material (such as welding glass) is used to fix the precisely arranged fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com