Energy displacement ventilating system and spiral energy displacement device

A displacement ventilation and spiral technology, applied in the field of ventilation systems, can solve the problems of easy fatigue, energy waste, high energy consumption, etc., and achieve the effect of strengthening circulation, reducing energy consumption, and reducing the harassment of outdoor noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The invention will be described in further detail below in conjunction with the accompanying drawings.

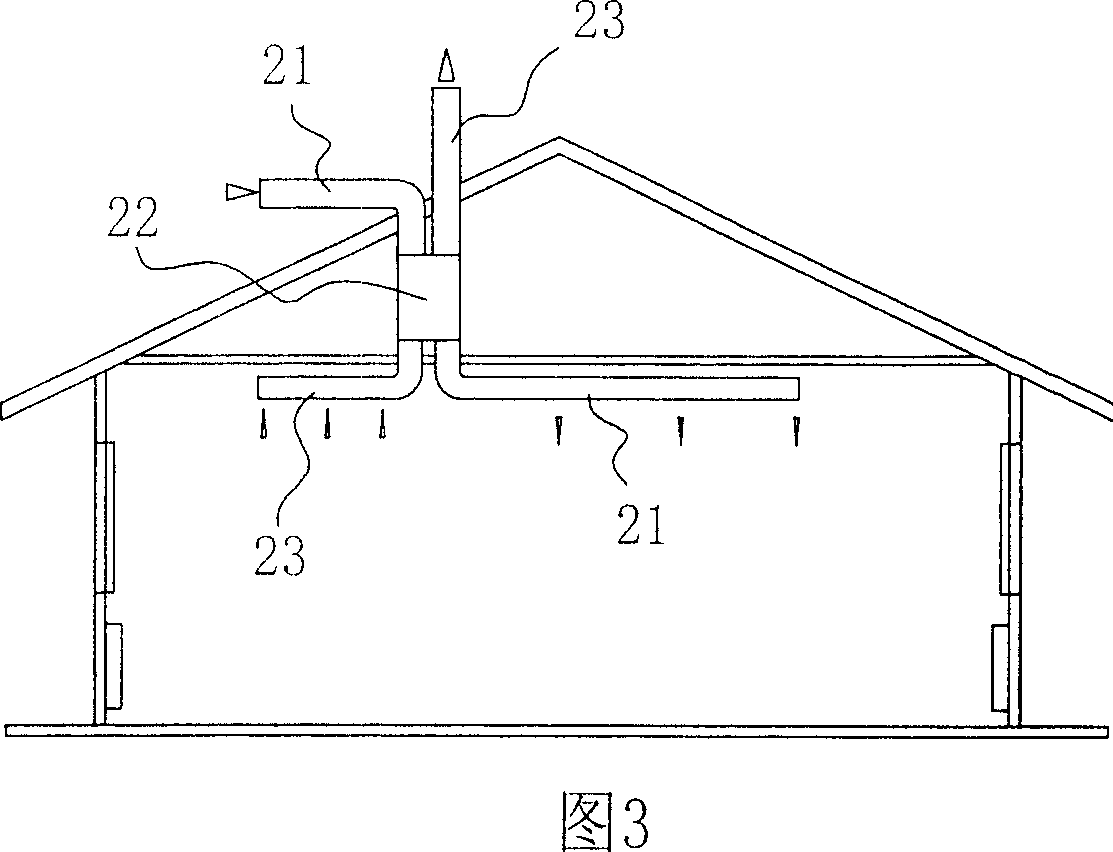

[0029] As shown in Figure 3, the energy displacement ventilation system of the present invention is mainly made up of air inlet pipe 21, air exhaust pipe 23 and spiral energy displacer 22, and air inlet pipe 21 and exhaust air pipe 23 are connected with the spiral energy displacer 22 respectively. The air inlet is communicated with the air outlet, and electric fans are respectively installed on the air inlet pipe 21 and the air exhaust pipe 23 to drive the air circulation to take a breath.

[0030] As shown in Figure 4 and Figure 5, the spiral energy displacer 22 is mainly composed of a cylindrical shell 2 and a double vortex inner core 4, the double vortex inner core 4 is separated by two thin plates 1 through the isolation medium 3 and rolled into a double vortex The two-layer thin plate 1 is rolled into a vortex-shaped cylinder and fixed by a solid barrel-shaped s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com