Touch glow-discharge plasma generating apparatus

A plasma and generating device technology, applied in the field of ion generating devices, can solve the problems of poor sewage treatment ability, unsuitable for industrialization, and small discharge area, etc., and achieve the effect of multiple discharge points, strong sewage treatment ability, and large discharge area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

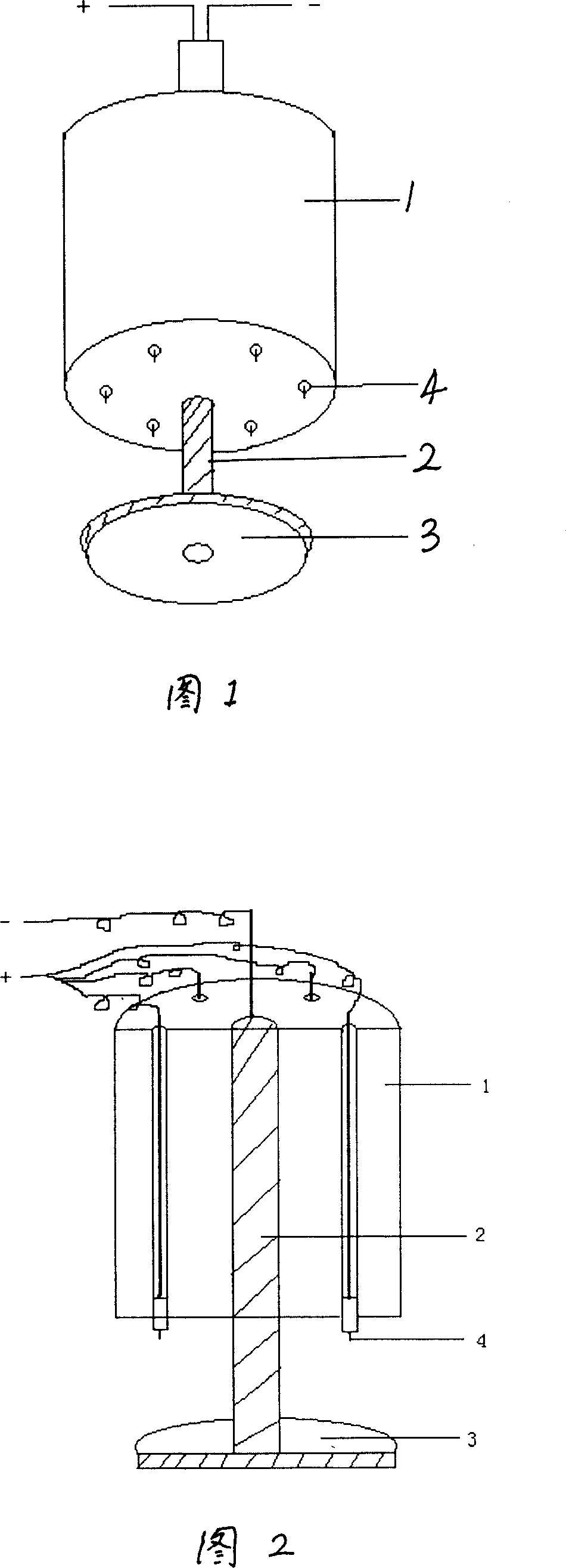

[0014] The contact glow discharge plasma generator includes an electrode carrier, a cathode and an anode. The electrode carrier 1 is a cylindrical polytetrafluoroethylene rod with a diameter of 6 cm, and the height can be selected according to actual needs. A hole with an inner diameter of 1.3 cm is inserted in the center of one end, and the cathode carbon rod 2 is inserted into the hole so that the length of the carbon rod outside the carrier is 3-7 cm; the thickness of the lower end of the carbon rod is 0.5-2 cm, and the diameter is 0.5-2 cm. The 3-6 cm disc-shaped graphite sheet 3 constitutes a sheet-shaped graphite cathode. Along the circumference 1 cm away from the cross-sectional edge of the PTFE rod 1, six holes with a diameter of 0.6 cm were opened, and the anode platinum electrode 4 was inserted into each hole, and the anode platinum electrode 4 was exposed at the lower end of the carrier 1 by 0.5- 1 cm. The platinum electrode 4 is to insert a platinum wire with a diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com