Fiber discharge electrode and preparation method thereof

A discharge electrode and fiber technology, which is applied in the field of fiber discharge electrodes and its preparation, can solve problems such as difficulty in ensuring the quality and stability of electrode products, and achieve the effects of low-concentration ozone discharge, good positioning, and convenient manufacturing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

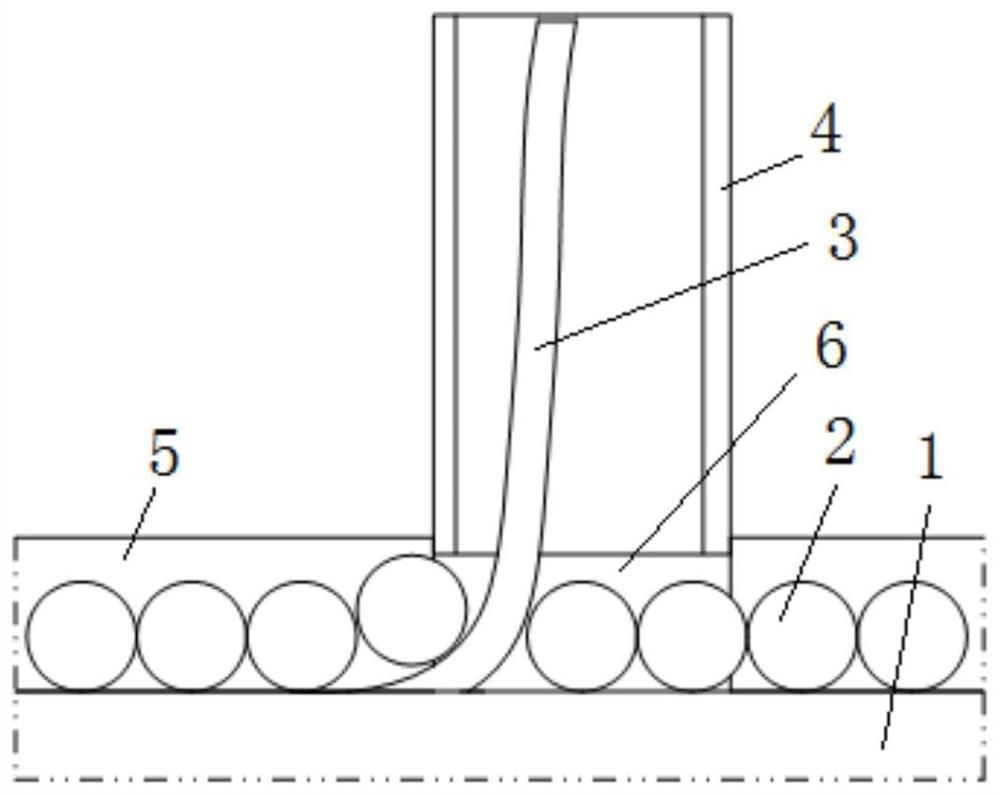

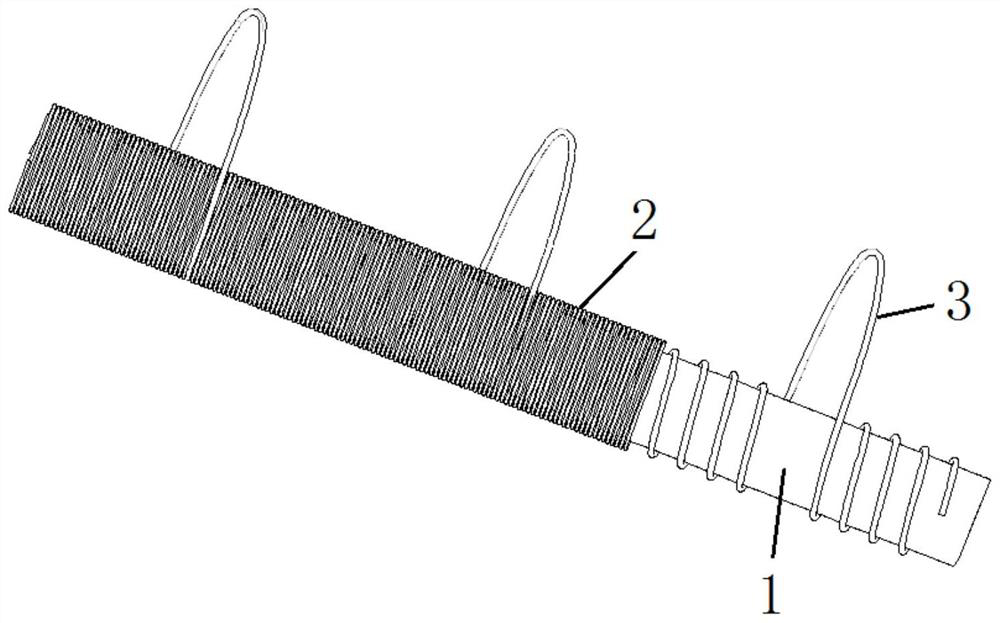

[0052] A fiber discharge electrode, such as figure 1 As shown, it includes: a conductive column 1, a fixed metal wire 2, and a conductive fiber bundle 3; wherein, the fixed metal wire 2 is wound on the conductive column 1 and forms several coils along the radial direction of the conductive column 1; the conductive fiber bundle 3 includes The fixed section and the extension section, the fixed section is fastened between the conductive column 1 and the fixed metal wire 2 by the winding force of the fixed metal wire 2 on the conductive column 1, and the extended section extends out of the fixed metal through the gap between adjacent coils. Silk 2.

[0053] The above-mentioned fiber discharge electrode provided by the present invention uses fiber bundles instead of needle-shaped electrodes, which can have more discharge points and thus have higher discharge efficiency. When only plasma with a fixed concentration needs to be provided, the discharge voltage can be increased. Reduce...

Embodiment 2

[0063] A preparation method of a fiber discharge electrode, specifically comprising:

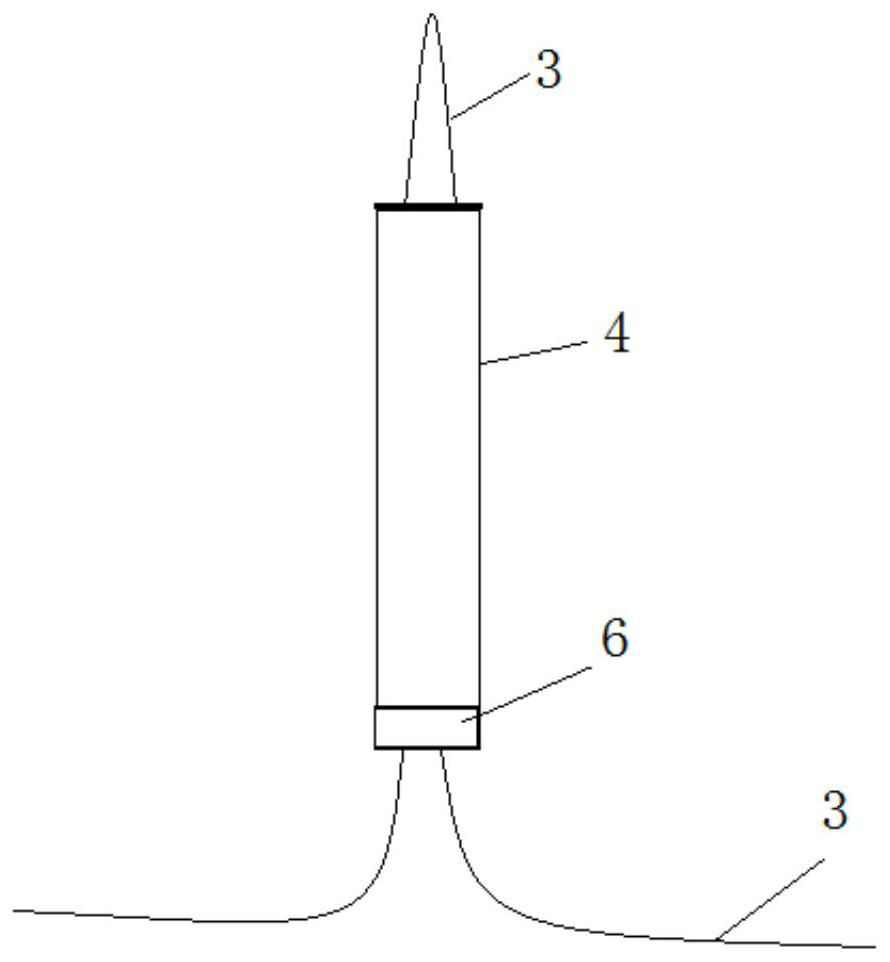

[0064] Obtain a copper conductive column 1, a copper fixed wire 2, a conductive fiber bundle composed of polyacrylonitrile carbon fiber 3, an insulating sleeve 4, a conductive glue 6, and a resin for sealing;

[0065] One end of the conductive fiber bundle 3 is spirally wound on the conductive column 1, and at the same time, a fixed metal wire 2 is also spirally wound on the conductive column 1 wound with the conductive fiber bundle 3 at the same end, so that the conductive fiber bundle 3 is tightly fixed on the conductive column 1. On the conductive column 1; when the conductive fiber bundle 3 moves to the position that needs to be extended during the winding process, extend the free end of the conductive fiber bundle 3 out of the fixed wire 2, and then bypass the extended conductive fiber bundle 3 to continue fixing Metal wire 2 is spirally wound, and after at least one turn, the conductiv...

Embodiment 3

[0069] This embodiment further provides an optimization scheme for the preparation method of a fiber discharge electrode, that is, before the conductive fiber bundle 3 is wound around the conductive column 1, the pretreatment of the conductive fiber bundle 3 is also carried out, as follows:

[0070] 1) Ethanol + ultrasonic cleaning, drying, suitable for laboratory level applications;

[0071] 2) In a muffle furnace, calcined at 800°C for 0.5-1h, and removed by high-temperature carbonization, suitable for small batch trial production;

[0072] 3) Under the protection of nitrogen, the high current is energized, and the current is controlled so that the carbon fiber becomes red (about 800-1000 ° C) visible to the naked eye. Keep it for 10 minutes and then cool it under nitrogen protection, which is suitable for mass continuous production.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Monofilament diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com