Ring-shaped tooth needle cathode ray of electric defogger

A technology of electric mist eliminators and ring teeth, applied in the direction of electrode structure, electrostatic separation, etc., to achieve the effect of preventing corrosion, long running time and good demisting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

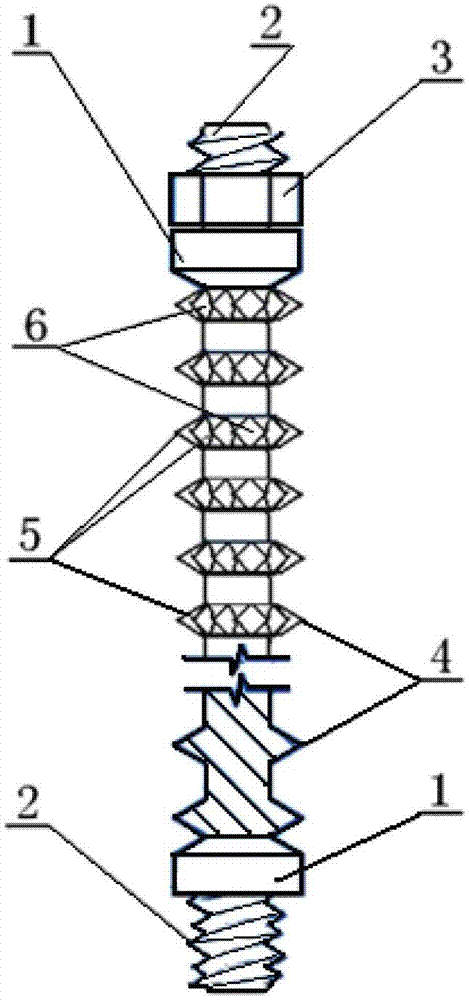

[0032] The present invention is a ring-shaped needle cathode wire of an electric demister, comprising a cathode rod 1, a terminal 2, a nut 3, a ring needle 4, a tooth needle 5, and a tooth needle chute 6. The cathode rod 1 is a 6mm solid circular stainless steel metal with a total length of 6 meters. On the cathode rod 1, ring needles 4 are arranged with a parallel spacing of 20 mm. The ring needles are provided with 10 toothed needles. blade. The terminal 2 at both ends of the cathode rod 1 is a thread structure, the nominal diameter of the thread is 6 mm, and the length is 5 cm. The terminal is equipped with a nut 3 with a length of 5 cm for fastening.

[0033] The method of use is: hang the cathode wire in the anode tube, the terminal of one end of the cathode wire is fixed on the cathode frame of the electric demister through a nut, and the terminal of the other end is hung with a weight and connected to the lower guide frame of the electric demister. As a whole, relying ...

Embodiment 2

[0036] The cathode wire setting includes a cathode rod 1, a terminal 2, a nut 3, a ring needle 4, a tooth needle 5, and a tooth needle chute 6. The cathode rod 1 is a solid circular stainless steel metal with a diameter of 8mm, and the total length is 8 meters. On the cathode rod 1, tooth pins 5 are arranged with a parallel spacing of 40 mm. The terminal 2 at both ends of the cathode rod 1 is a thread structure, the nominal diameter of the thread is 6 mm, and the length is 5 cm. The terminal is equipped with a nut 3 with a length of 5 cm for fastening.

[0037] The method of use is: hang the cathode wire in the anode tube, the terminal of one end of the cathode wire is fixed on the cathode frame of the electric demister through a nut, and the terminal of the other end is hung with a weight and connected to the lower guide frame of the electric demister. As a whole, relying on the weight of the weight and the weight of the cathode wire itself, the cathode wire can maintain high...

Embodiment 3

[0040] The cathode wire setting includes a cathode rod 1, a terminal 2, a nut 3, a ring needle 4, a tooth needle 5, and a tooth needle chute 6. Cathode rod 1 is a solid circular stainless steel metal with a diameter of 6mm, with a total length of 5 meters. On the cathode rod 1, ring needles 4 are arranged with a parallel spacing of 20 mm. The terminal 2 at both ends of the cathode rod 1 is a thread structure, the nominal diameter of the thread is 6 mm, and the length is 5 cm. The terminal 2 is equipped with a nut 3 with a length of 5 cm for fastening.

[0041] The method of use is: hang the cathode wire in the anode tube, the terminal of one end of the cathode wire is fixed on the cathode frame of the electric demister through a nut, and the terminal of the other end is hung with a weight and connected to the lower guide frame of the electric demister. As a whole, relying on the weight of the weight and the weight of the cathode wire itself, the cathode wire can maintain high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com