Method for forming frame of bicycle

A molding method and bicycle technology, which can be applied to household components, household appliances, other household appliances, etc., can solve the problems of increased material cost, damage, poor fiber orientation, etc., and achieve the effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

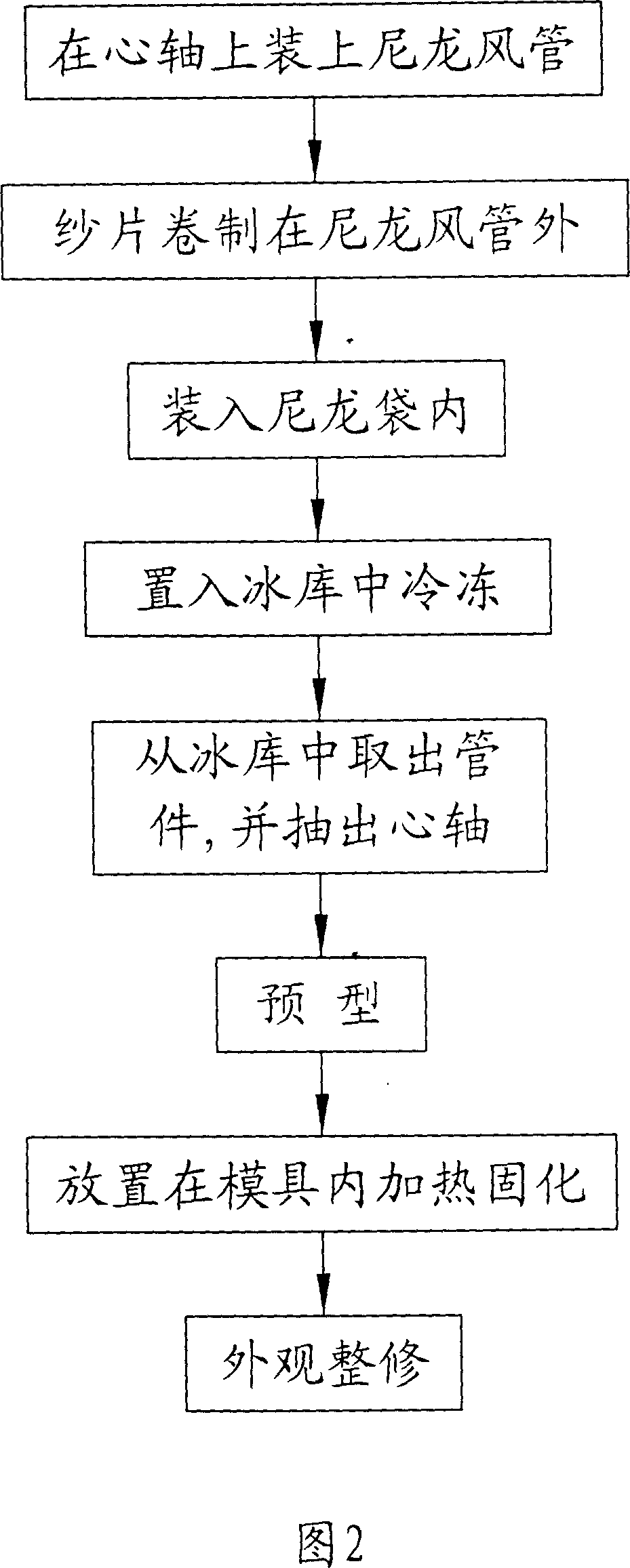

[0017] As shown in Figure 2, the molding method of bicycle frame of the present invention is:

[0018] 1. First, install the nylon air duct on the mandrel;

[0019] 2. After impregnating the yarn with resin, roll it outside the nylon air pipe to form the rough shape of each pipe fitting of the frame;

[0020] 3. Then put the pipe fittings into the freezer to freeze, the temperature in the freezer is controlled at 0 to minus 20 degrees Celsius, freeze for 1 to 5 hours, and shape the pipe fittings;

[0021] 4. Then take the pipe fittings out of the freezer and pull out the mandrel;

[0022] 5. Preform the frame pipe fittings in a low-temperature room with an ambient temperature below 20 degrees Celsius, that is, cut out the joint gaps at the joints of each pipe fittings and then splice them. After splicing, the joints will be covered with reinforcing yarn. In this preforming process, it takes a certain amount of time for the temperature to rise. Therefore, when the reinforcing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com