Device for cooling down melt-spun filaments and melt-spinning device

A cooling device, melt spinning technology, applied in textiles and papermaking, application, heating methods, etc., to achieve high flexibility and good adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

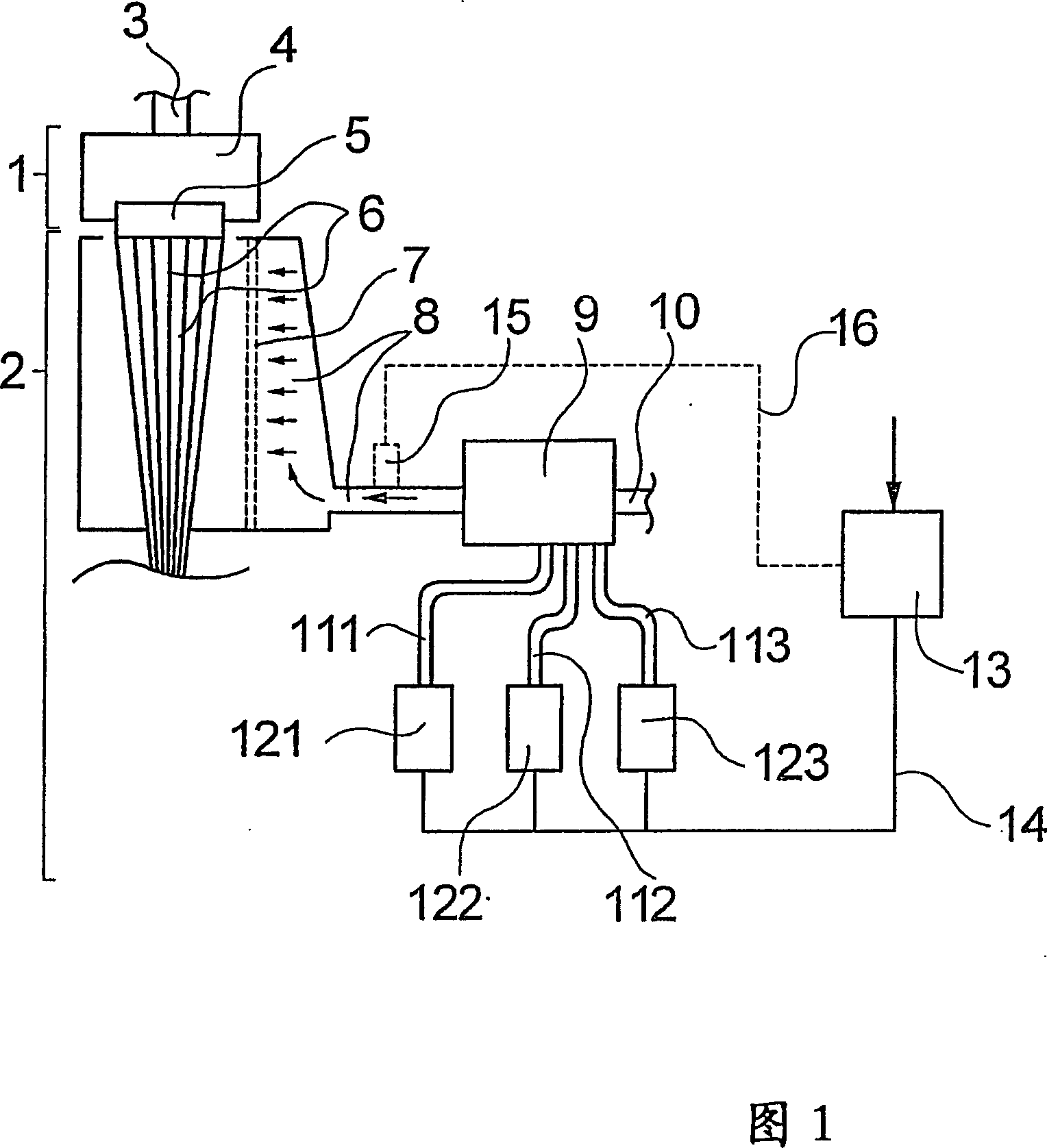

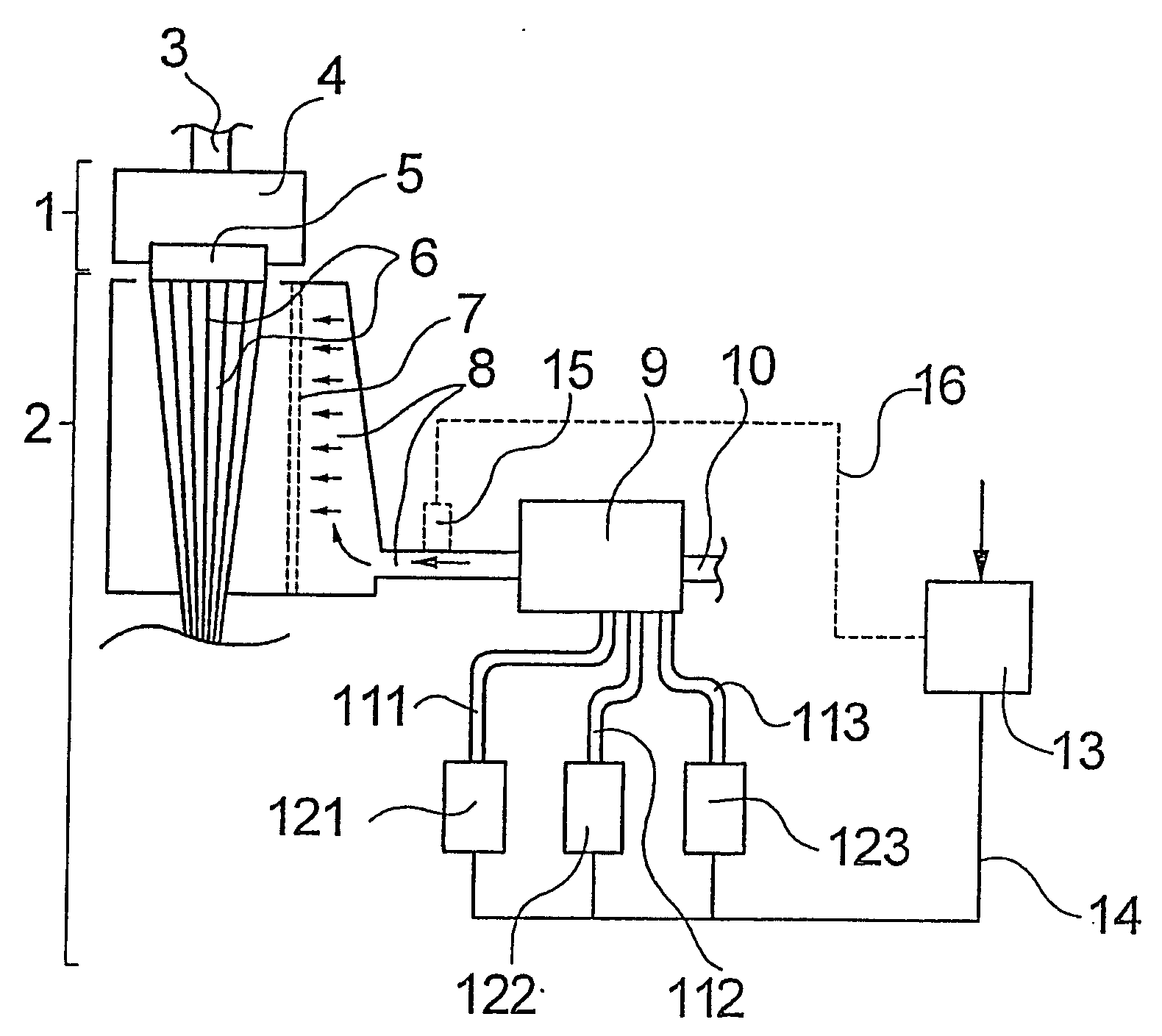

[0029] FIG. 1 shows an exemplary embodiment of an apparatus according to the invention for melt spinning a plurality of strand-like monofilaments. The device has a spinning device 1 and a cooling device 2 located directly below the spinning device 1 . The spinning device 1 comprises a melt inlet 3 which is connected, for example, to a melt source (not shown here), such as an extruder or a pump. The melt inlet 3 leads to a spinning head 4 . On the underside of the spinneret 4 are provided one or more nozzle assemblies 5 containing a plurality of spinneret holes to extrude a plurality of strand-like monofilaments 6 .

[0030] A cooling channel 7 of the cooling device 2 surrounding the emerging filaments 6 is arranged below the nozzle assembly 5 . The cooling channel 7 is connected via an air inlet channel 8 to an outlet of a cooling fluid source 9 . Fresh air is supplied to the cooling fluid source 9 via an air inlet 10 arranged on the opposite side of the air supply channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com