Combined self-refluxing denitrogenating biological turntable

A biological turntable and self-return technology, applied in sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. The effect of energy saving, specific surface area and volume utilization improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

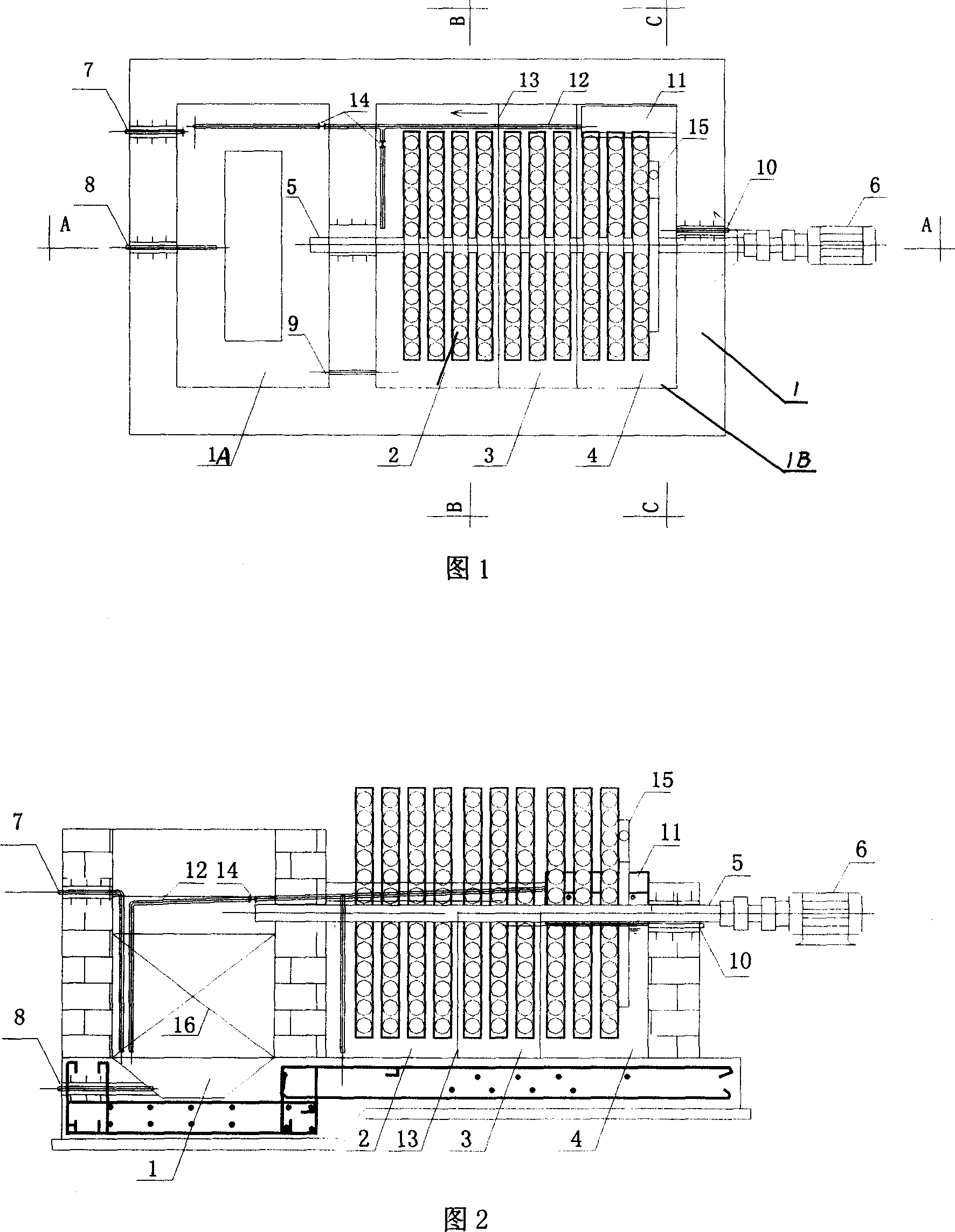

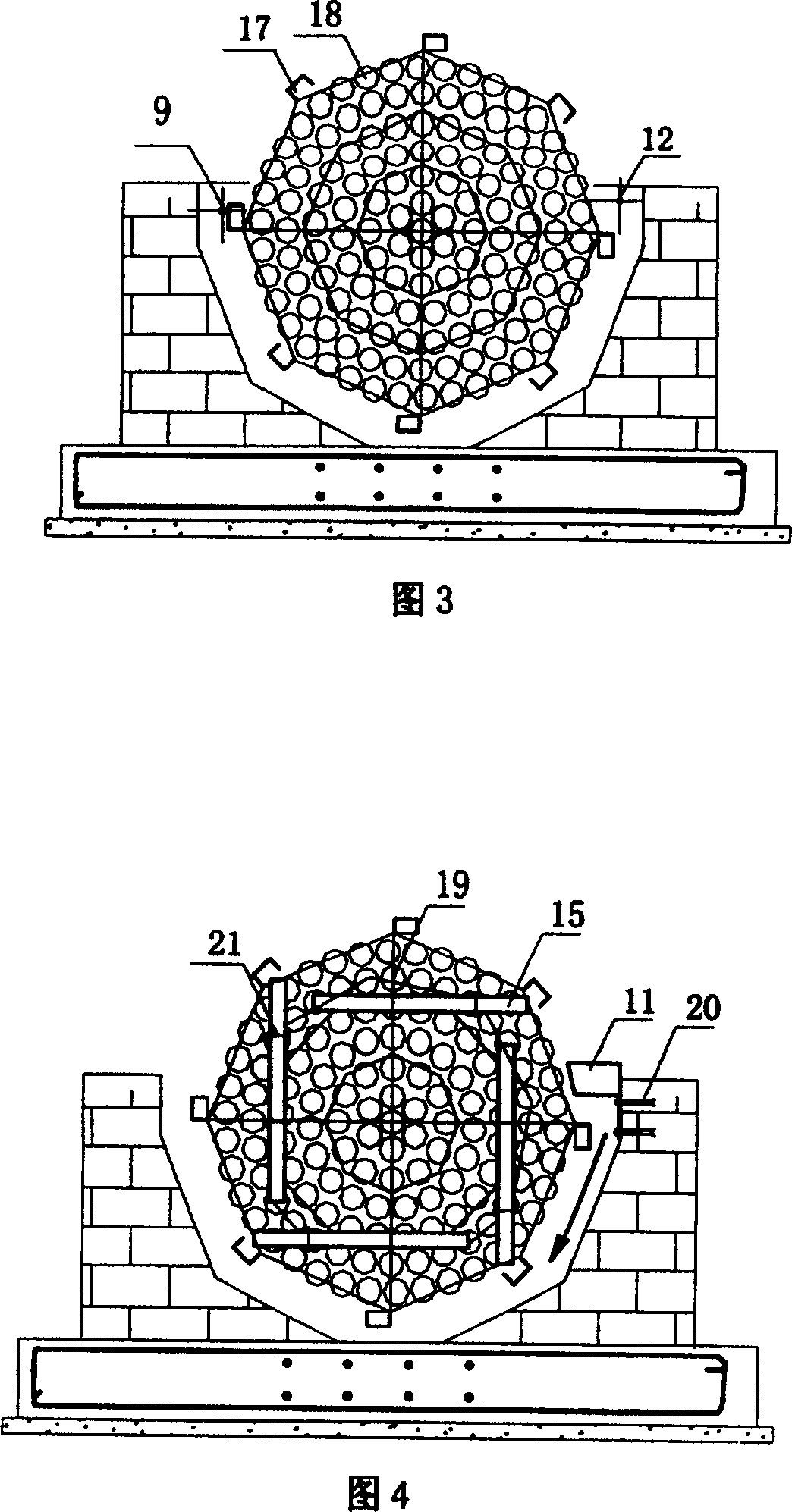

[0017] The filler-combined biological turntable frame of the present invention can adopt structures such as glass fiber reinforced plastics and hard plastics, and the gap between the disks is 90 mm, and 80 mm combined spherical fillers or elastic fillers can be filled. The riser is made of PVC or FRP round pipe or square pipe. As the turntable rotates, the riser is sometimes submerged in the water and sometimes exposed to the water. Water enters when the riser is submerged in water, and starts to discharge water after it is rotated to a horizontal position in the air. The water inlet and the water outlet are shared and are arranged at one end of the riser. An air outlet needs to be provided at the other end to ensure that the water can fill the riser. By changing the size and number of risers (1 to 4), the return rate can be adjusted. The backflow generally returns to the denitrification tank, and the submergence rate of the first-stage biological turntable is controlled to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com