Composite biocarrier for wastewater treatment

A biological carrier and wastewater treatment technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve the problems of long time required for film formation and difficult film formation on the outer surface of the carrier , to achieve the effect of improving wastewater treatment efficiency, no need for replacement and maintenance, and fast metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Implementation Example 1

[0027] Take 0.2kg of talc powder with a fineness above 100 mesh, 2kg of slag powder, 0.8kg of ferric oxide, 2kg of coke, 1kg of starch, and 2kg of cationic polyacrylamide, and then add 72kg of high-density polyethylene. Extrude into the barrel, heat up the extruder, the temperature of the body reaches 135°C, and the temperature of the head reaches 130°C. The composite biological carrier for waste water treatment described in the present invention can be made.

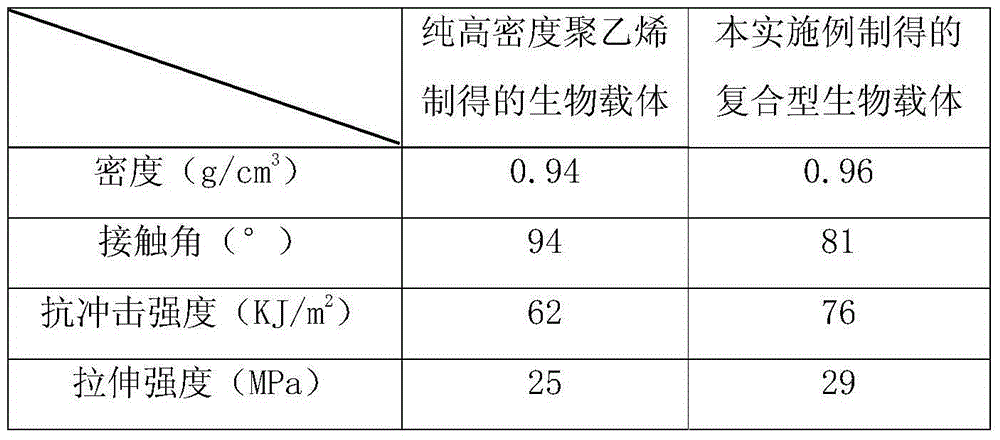

[0028] The density, contact angle, impact strength and tensile strength of the composite biological carrier for wastewater treatment prepared in this example are compared with the biological carrier directly prepared from pure high-density polyethylene, and the comparison results are as follows:

[0029]

[0030] Implementation Example 2

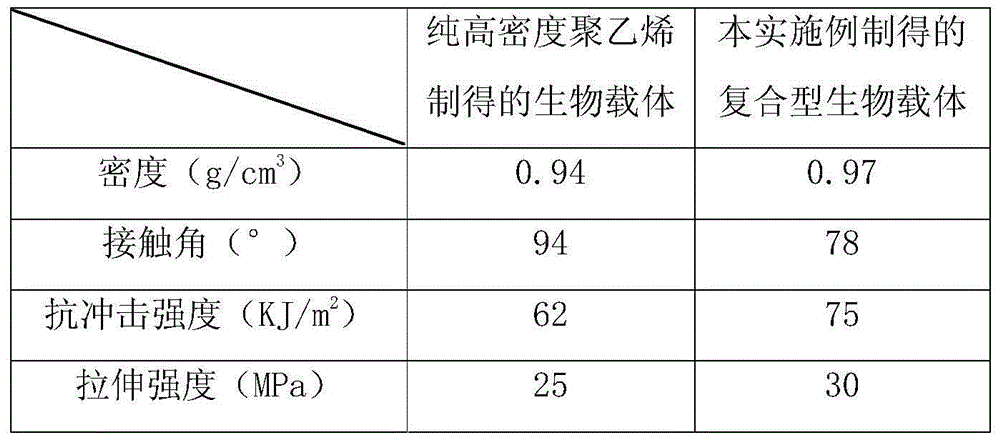

[0031] Take 0.2kg of talc powder with a fineness of 100 mesh or more, 2kg of slag powder, 0.8kg of ferric oxide, 2kg of coke, 1kg of starch, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com