Full-automatic glue making machine and full-automatic control method

A fully automatic and pneumatic control valve technology, which is applied in the field of rubber making machines, can solve the problems of poor product quality, inaccuracy, and low production efficiency, and achieve the effects of stable product quality, good product quality, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

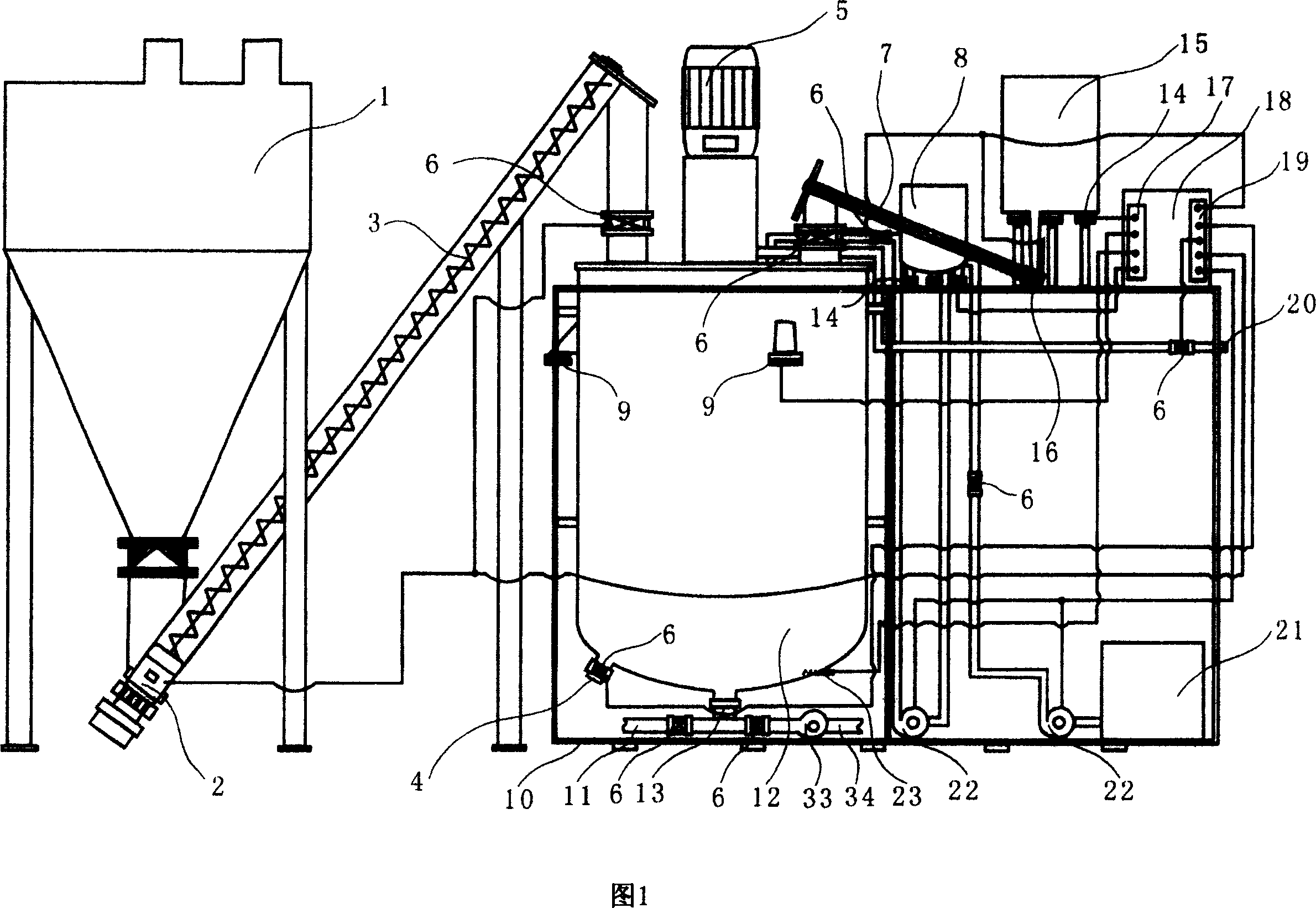

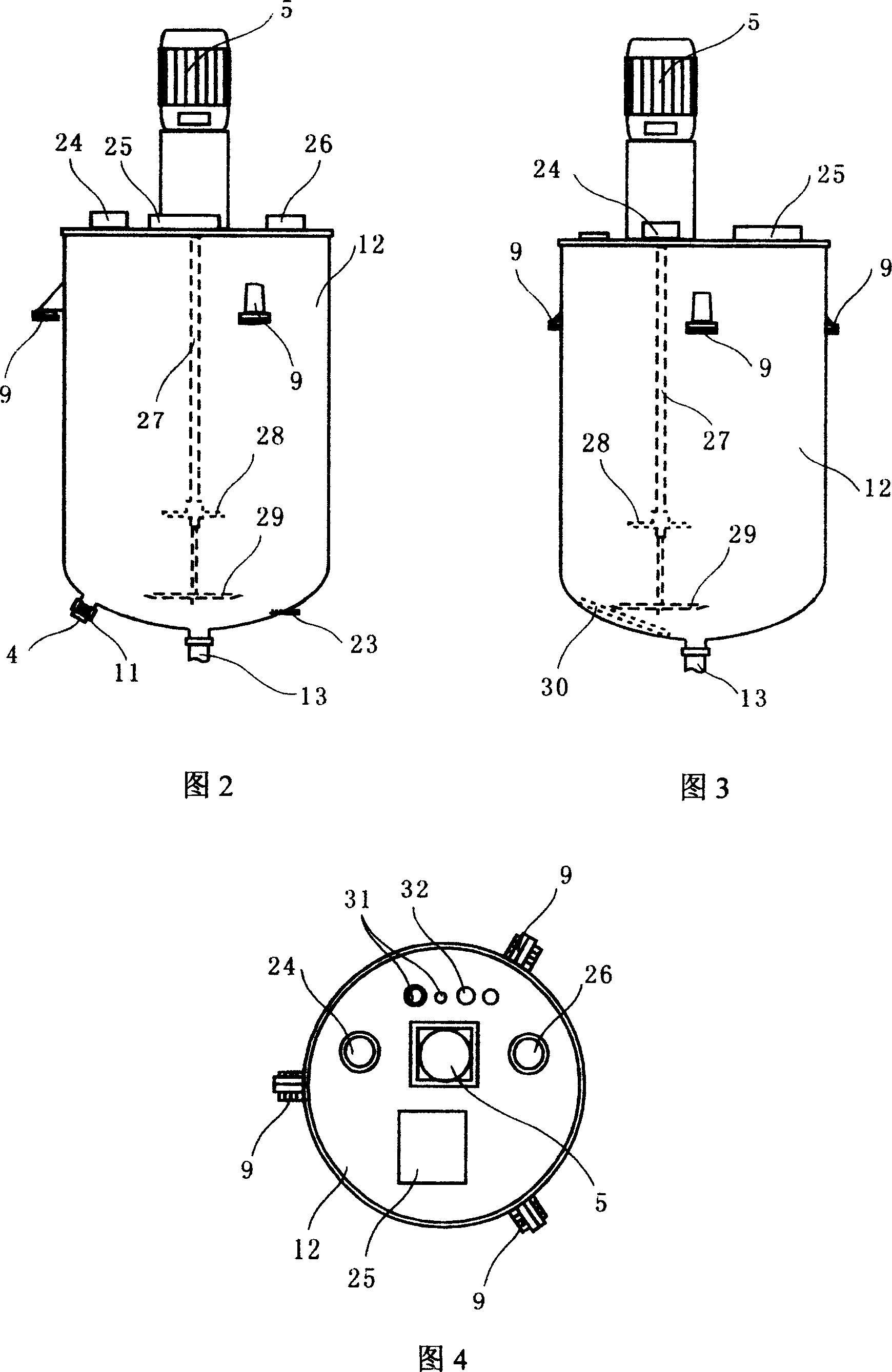

[0032] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0033]As shown in Figure 1, a main tank 12 is installed on the bearing frame 10, and its discharge port 13 is positioned at the below of the main tank 12, a steam pipe interface 4 is arranged at the bottom of the main tank 12, and various The feeding port of raw material is also equipped with stirring motor 5, starch storage tank 1 is installed beside load-bearing frame 10, and borax storage tank 15, lye transfer tank 8, lye storage tank 21 and lye storage tank 21 are also installed on load-bearing frame 10. Automatic control box 18; Starch propeller 3 is installed between the discharge port of starch storage tank 1 and the starch feed port of main tank 12, and the borax feed port of main tank 12 is installed at the discharge port of borax storage tank 15 Borax propeller 7 is installed between, and the liquid outlet of lye storage tank 21 is connected with the liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com