Method for producing a transistor structure

A transistor, bipolar transistor technology, used in transistors, semiconductor/solid state device manufacturing, electric solid state devices, etc., to achieve low marginal capacitance, improved high current behavior, and reduced conduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

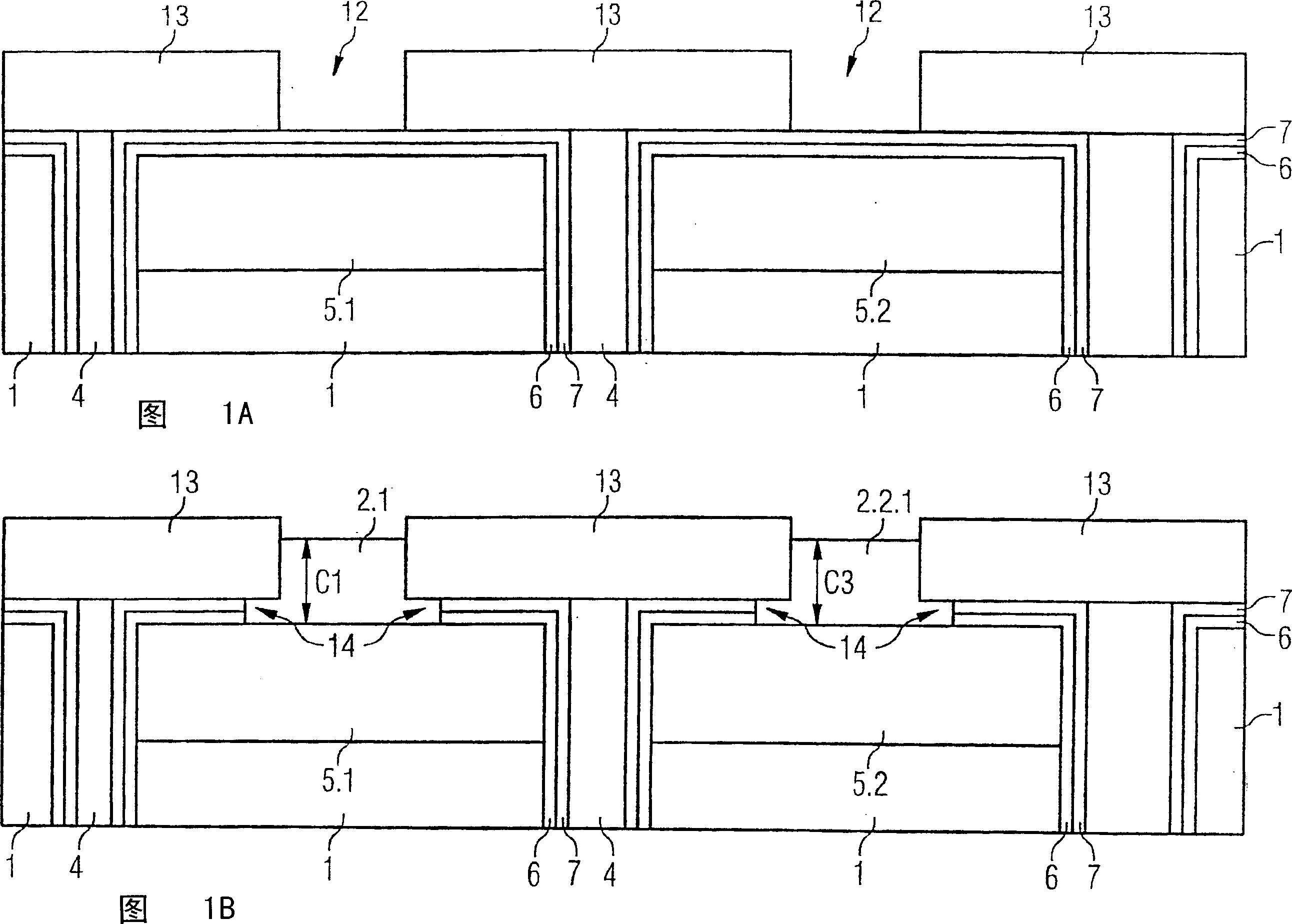

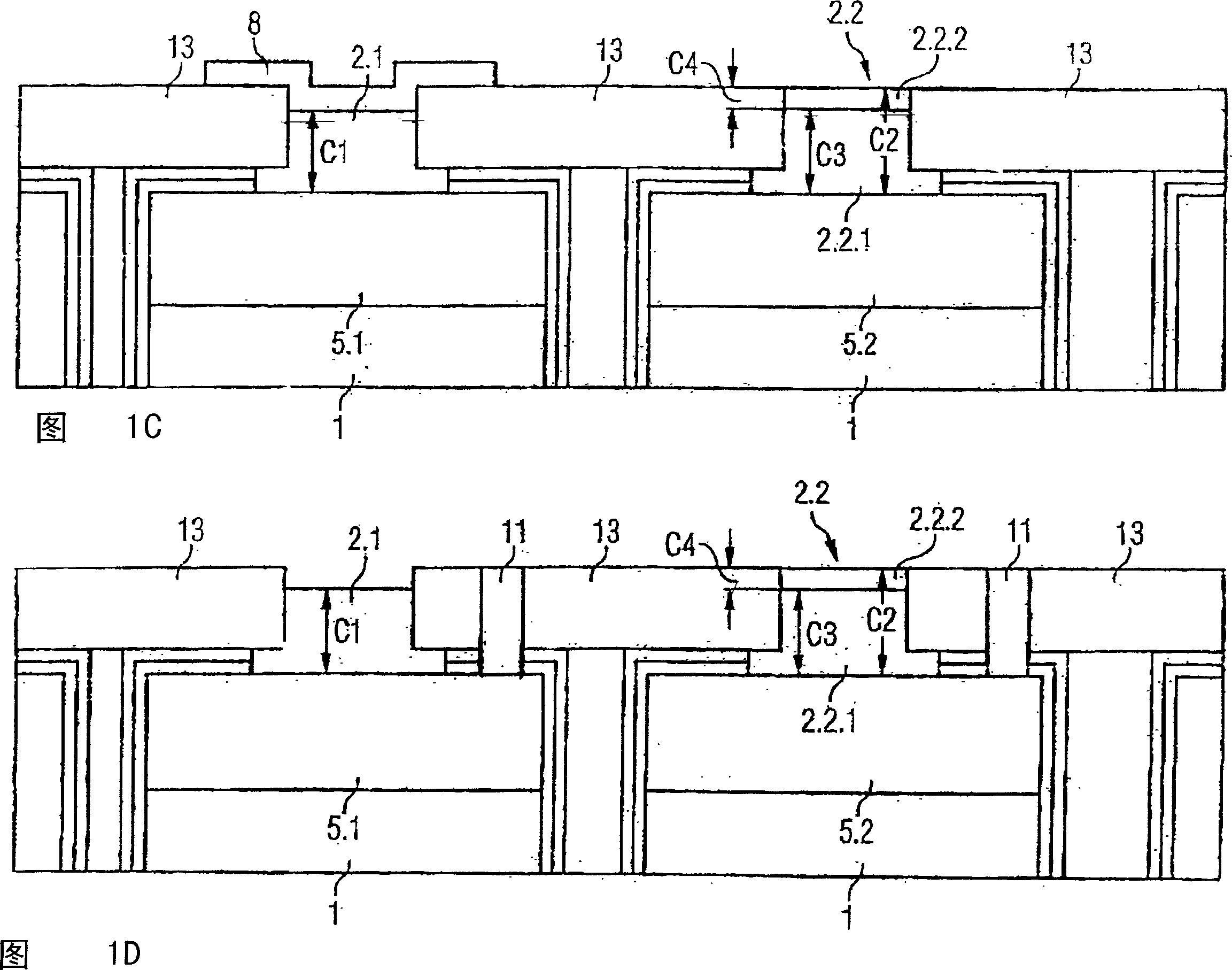

[0027] According to the first method of the present invention, a transistor structure for manufacturing two collector regions with different collector widths according to the present invention, as shown in the appended reference drawings FIGS. 1A to 1D , has been It is implemented by the technique of selective seeding.

[0028] The buried layer described in Figure 1A is, for example, n + Type-doped buried layers 5.1 and 5.2 have been introduced into the semiconductor substrate 1 and are insulated from each other by an insulating layer 4, here a deep trench 4 is formed. The semiconductor substrate 1 includes, for example, p-type doped single crystal silicon.

[0029] A first sublayer 6 and a second sublayer 7 are further provided and insulate the insulating layer 4 from the semiconductor substrate 1 and the buried layers 5.1 and 5.2. In this example, the second subsidiary layer 7 is adjacent to the insulating layer 4, and the first subsidiary layer 6 is adjacent to the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com