Wafer package structure and its base plate

A chip packaging and substrate technology, which is used in electrical components, electrical solid-state devices, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The specific structure, features and functions of the chip package structure and its substrate according to the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

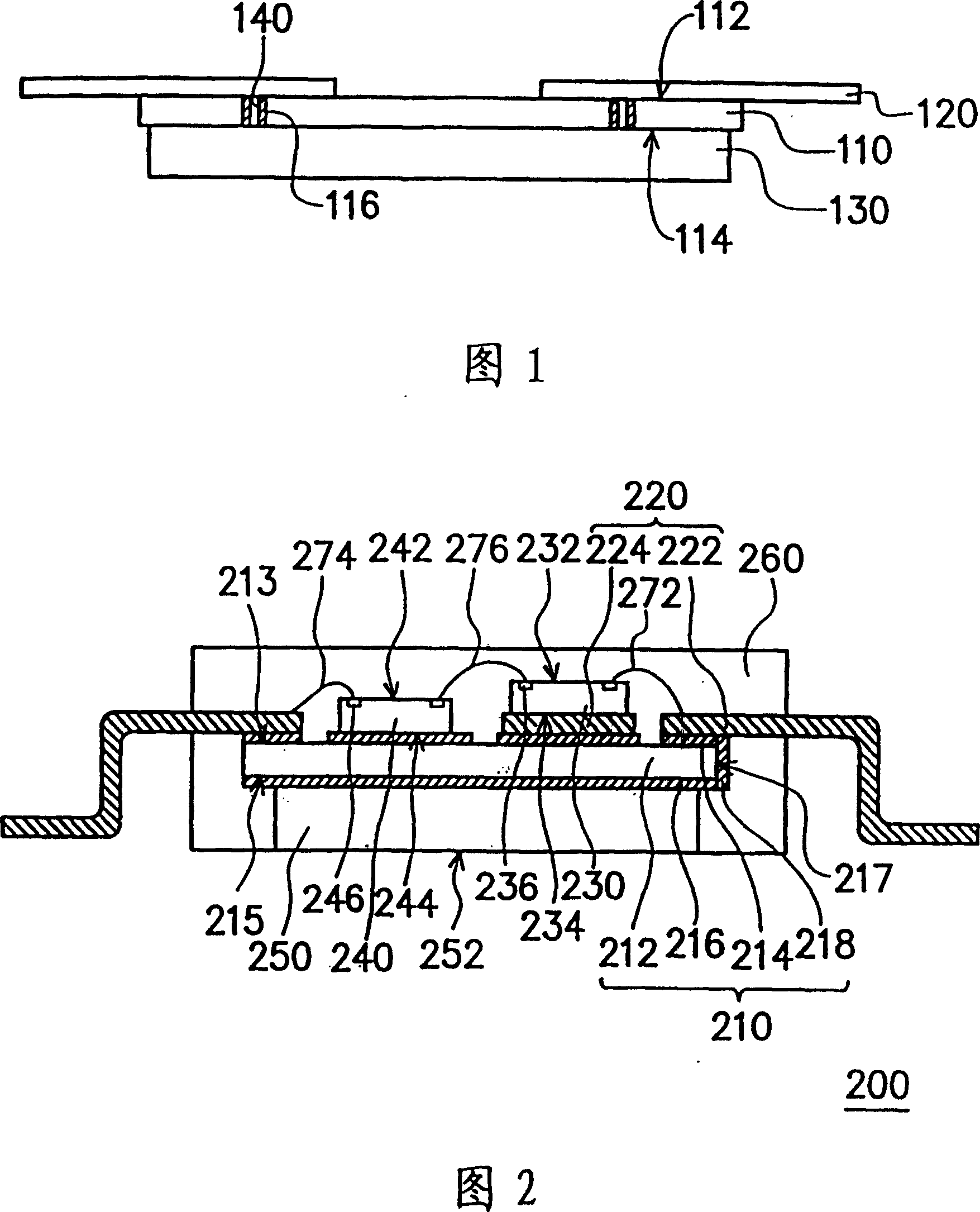

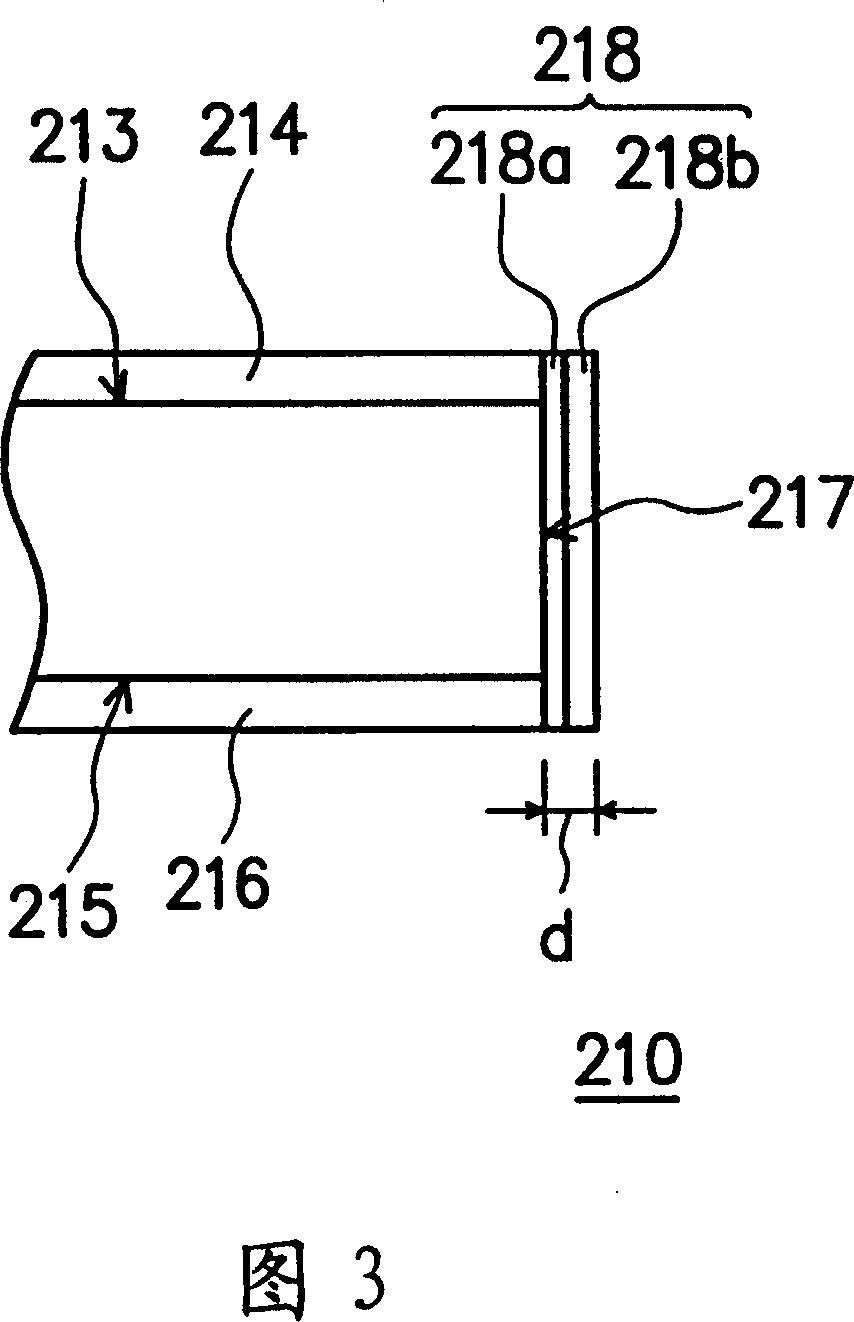

[0055] Please refer to FIG. 2 , which is a schematic cross-sectional view of a chip package structure of a high-power power module according to a preferred embodiment of the present invention. Generally speaking, the chip packaging structure 200 of the high-power power module includes a substrate 210 , a lead frame 220 , chips 230 , 240 , a heat sink 250 , a packaging material 260 and bonding wires 272 , 274 , 276 .

[0056] The substrate 210 is, for example, composed of an insulating layer 212, metal layers 214, 216 and a conductor 218, wherein the metal layer 214 is located on the upper surface 213 of the insulating layer 212, and the metal layer 216 is located on the lower surface 215 of the insulating layer 212. Above, the conductor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com