Optical fiber and its mfg. method

An optical fiber and area technology, which is applied in the direction of glass fiber products, clad optical fibers, manufacturing tools, etc., can solve the problems that the transmission loss of optical fiber cannot be reduced, the effect of reducing transmission loss is not obtained, the transmission loss is not reduced or increased on the contrary, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, the best embodiment of the optical fiber of the present invention and its manufacturing method will be described in detail with reference to the drawings. In the description of the drawings, the same elements are given the same symbols, and repeated descriptions are omitted. The dimensional ratios in the drawings do not necessarily correspond to the descriptions.

[0038] First, the first optical fiber and the method for producing the optical fiber of the present invention will be described.

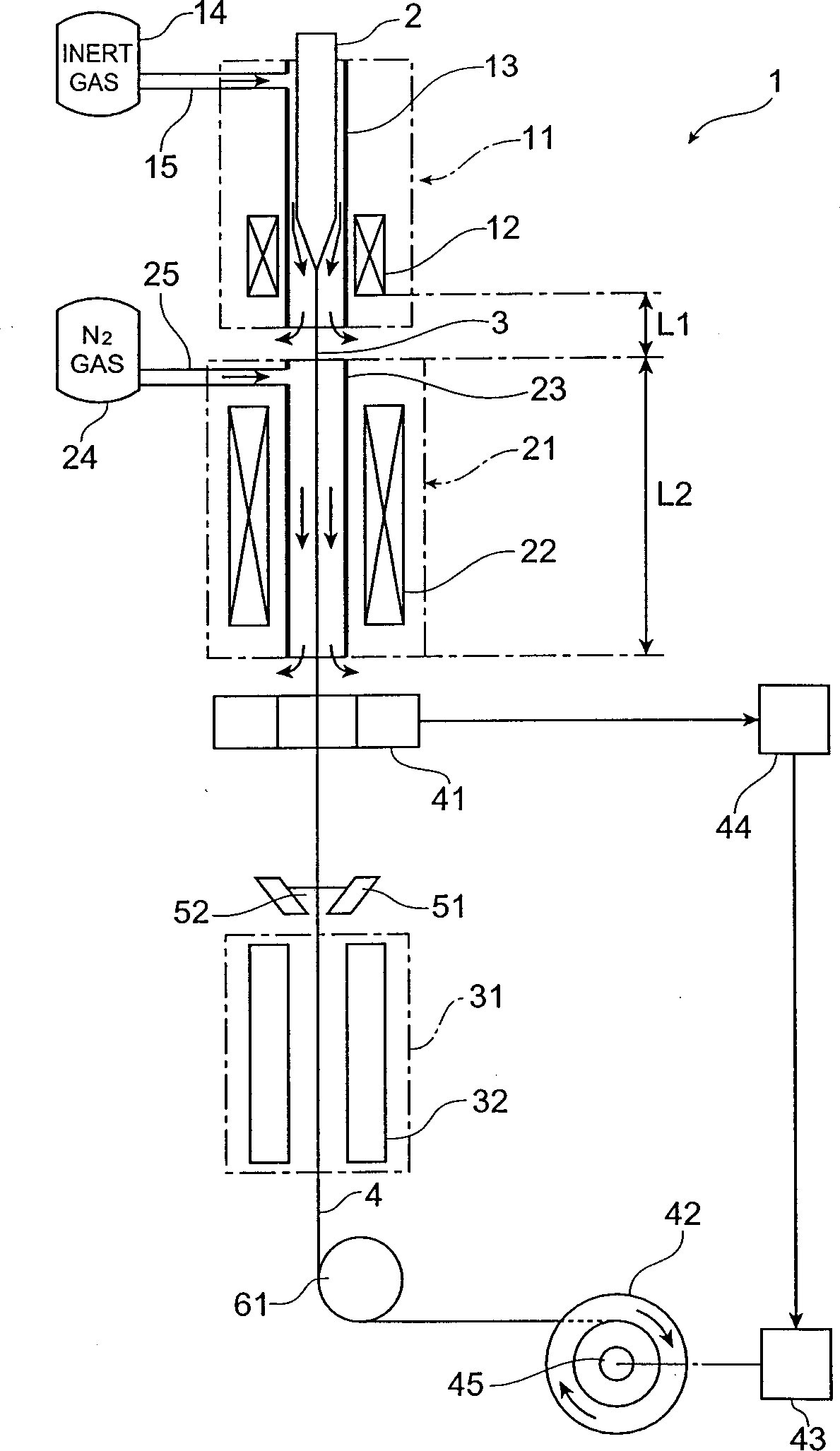

[0039] figure 1 The drawing device 1 shown is a drawing device for drawing quartz glass-based optical fibers, and includes a drawing furnace 11 , a heating furnace 21 for slow cooling, and a resin hardening part 31 . These wire drawing furnace 11, heating furnace 21 and resin hardening part 31 are in the direction of drawing mercerized optical fiber base material 2 ( figure 1 Up and down direction), the wire drawing furnace 11, the heating furnace 21, and the resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| residual stress | aaaaa | aaaaa |

| scattering coefficient | aaaaa | aaaaa |

| scattering coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com