Yttrium aluminum garnet powder without sintering aid, yttrium aluminum garnet ceramic, and preparation method and application thereof

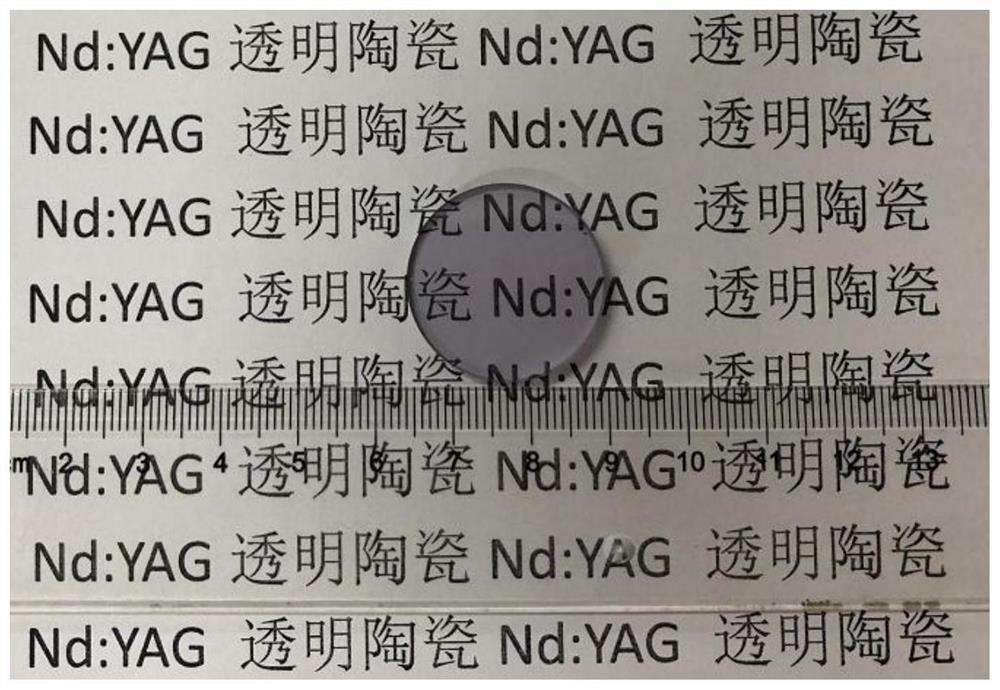

A powder and ceramic technology, applied in the field of laser transparent ceramic preparation, can solve the problems of long production cycle, high cost, difficulty in realizing high-concentration doping of rare earth and large-scale preparation, etc., and achieves clean grain boundaries and uniform grain size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

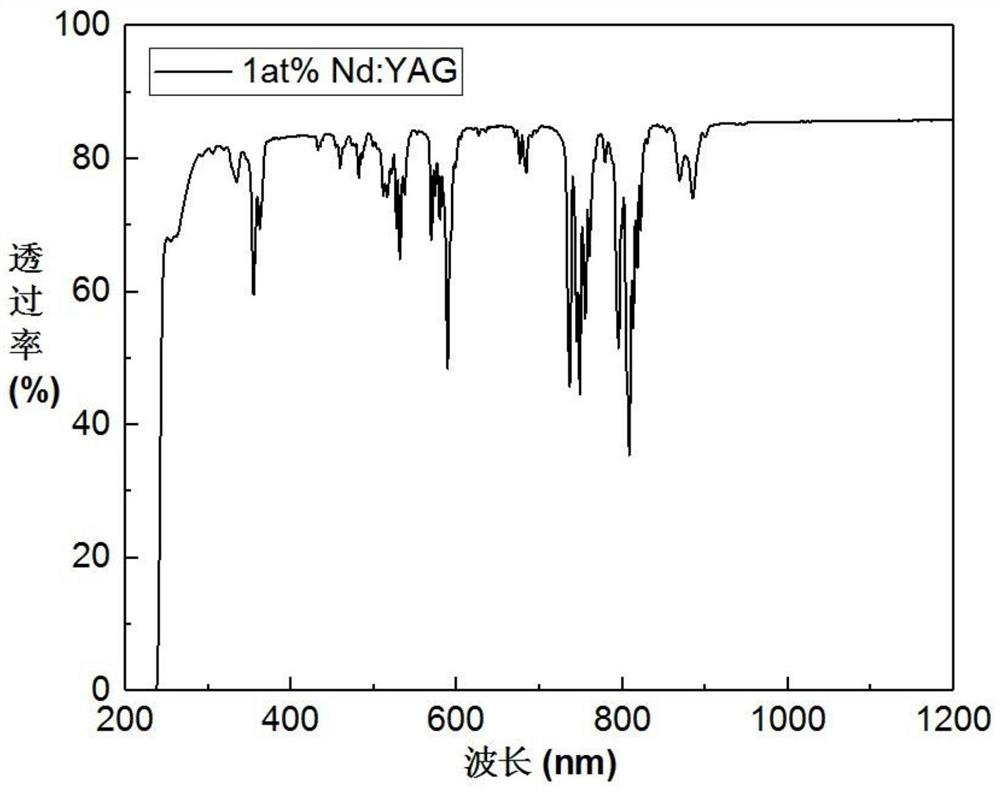

Embodiment 1

[0059] (1) According to (Nd 0.01 Y 0.99 ) 3 Al 5 o 12 The stoichiometric ratio of Nd 2 o 3 、Al 2 o 3 , Y 2 o 3 As a raw material, based on the total amount of all raw materials, add 0.5wt% binder polyvinyl butyral, 0.6wt% dispersant oleic acid, absolute ethanol ball mill, and alumina balls into an agate jar Ball milling for 18 hours;

[0060] (2) drying the slurry obtained in step (1) in an oven at 70°C;

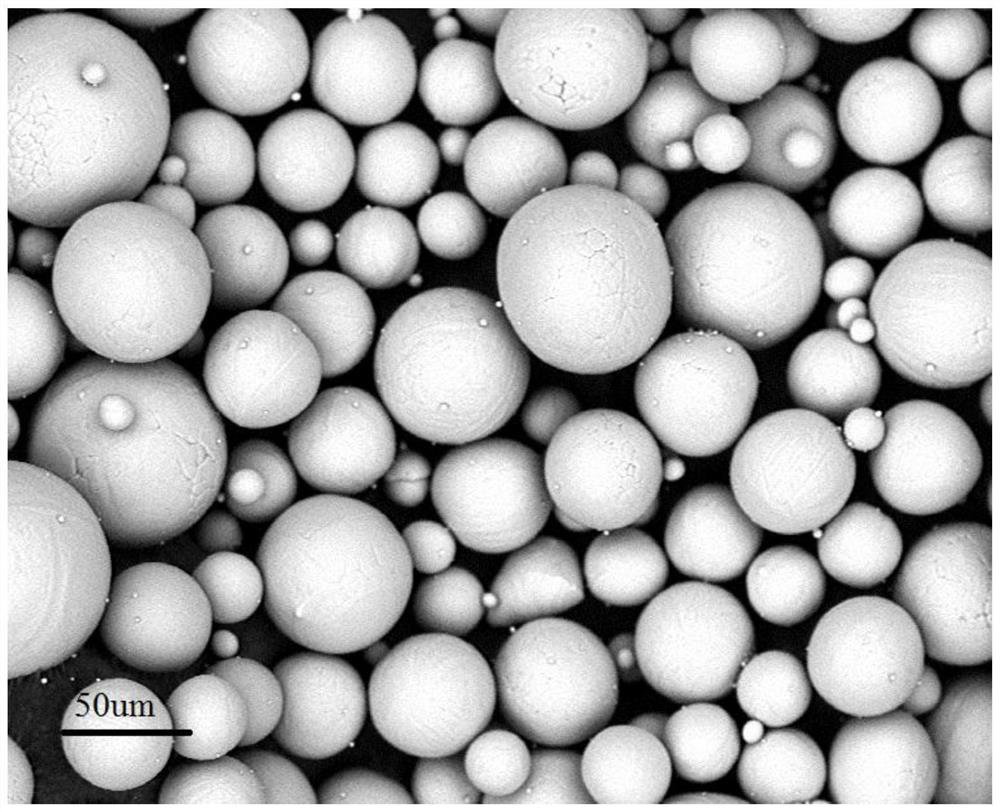

[0061] (3) the YAG coarse powder that step (2) obtains is carried out fluidized bed spheroidization, granulation, binder solution is 10% polyvinyl alcohol solution, and inlet air temperature is 74 ℃, and injection speed 10ml / min, The spray pressure is 0.2MPa, and the granulation is circulated for 3 times to obtain a spherical YAG powder with an average particle size of about 50 μm;

[0062] (4) Calcining the spherical YAG powder obtained in step (3) at 1350° C. for 2 hours in air to synthesize a pure YAG phase, and then cold isostatic pressing to obtain a ceramic...

Embodiment 2

[0070] (1) According to (Yb 0.02 Y 0.98 ) 3 Al 5 o 12 The stoichiometric ratio of Yb 2 o 3 、Al 2 o 3 , Y 2 o 3 For raw material, other steps are identical with example 1;

[0071] (2) Flash sinter the ceramic green body obtained in step (1), and sinter it at 1600° C. for 15 minutes under a pressure of 100 MPa to obtain a 2at% Yb:YAG transparent ceramic with an average grain size of about 3 μm.

[0072] Such as Figure 6 The average grain size of the 2at%Yb:YAG transparent ceramic shown is about 3 μm, YAG is completely dense, and there is no precipitation of amorphous phases and impurities at the grain boundary, the grain boundary is clean, and the grain size is uniform.

Embodiment 3

[0074] (1) According to Y 3 Al 5 o 12The stoichiometric ratio, adding 0.3wt% binder polyvinyl butyral, 1wt% dispersant oleic acid, absolute ethanol ball mill, and alumina balls were put into an agate jar for ball milling for 18 hours;

[0075] (2) drying the slurry obtained in step (1) in an oven at 70°C;

[0076] (3) The powder obtained in step (2) is subjected to fluidized bed spheroidization and granulation, the binder solution is 15% polyvinyl alcohol solution, the inlet air temperature is 76°C, and the injection speed is 15ml / min, spray The pressure is 0.4MPa, and the granulation is circulated for 3 times to obtain a spherical powder with a particle size of about 100 μm;

[0077] (4) Calcining the spherical powder obtained in step (3) at 1350° C. in air for 2 hours to synthesize a pure YAG phase, and then cold isostatic pressing to obtain a ceramic green body.

[0078] (5) The green body obtained in step (4) was sintered by spark plasma under a pressure of 30 MPa and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com