BWR type nuclear power generator and construction method

A nuclear energy and power station technology, applied in the field of power stations, can solve problems such as difficult standardized design, large amount of work and construction period, and economic problems, and achieve the effect of low cost and large size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

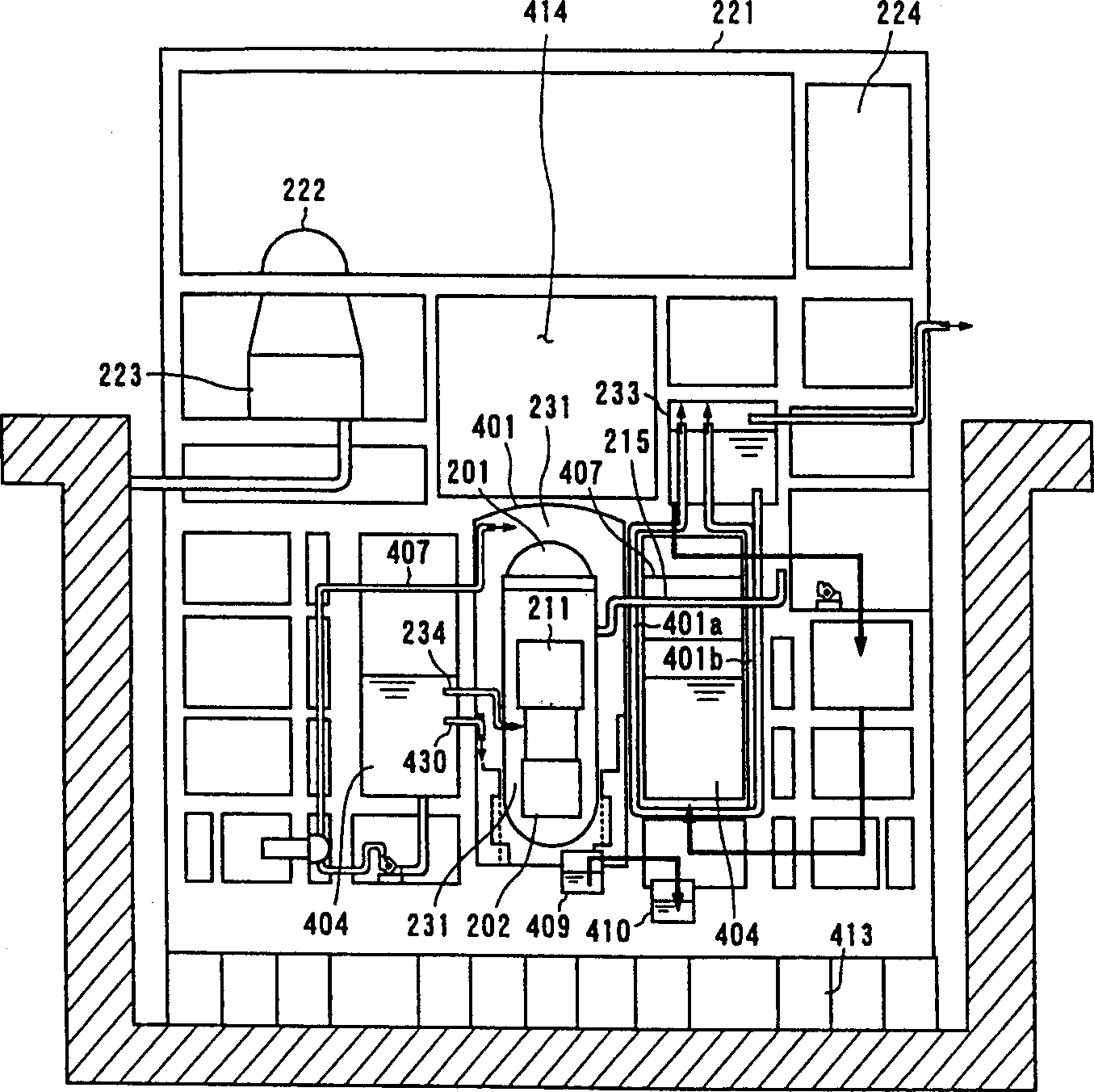

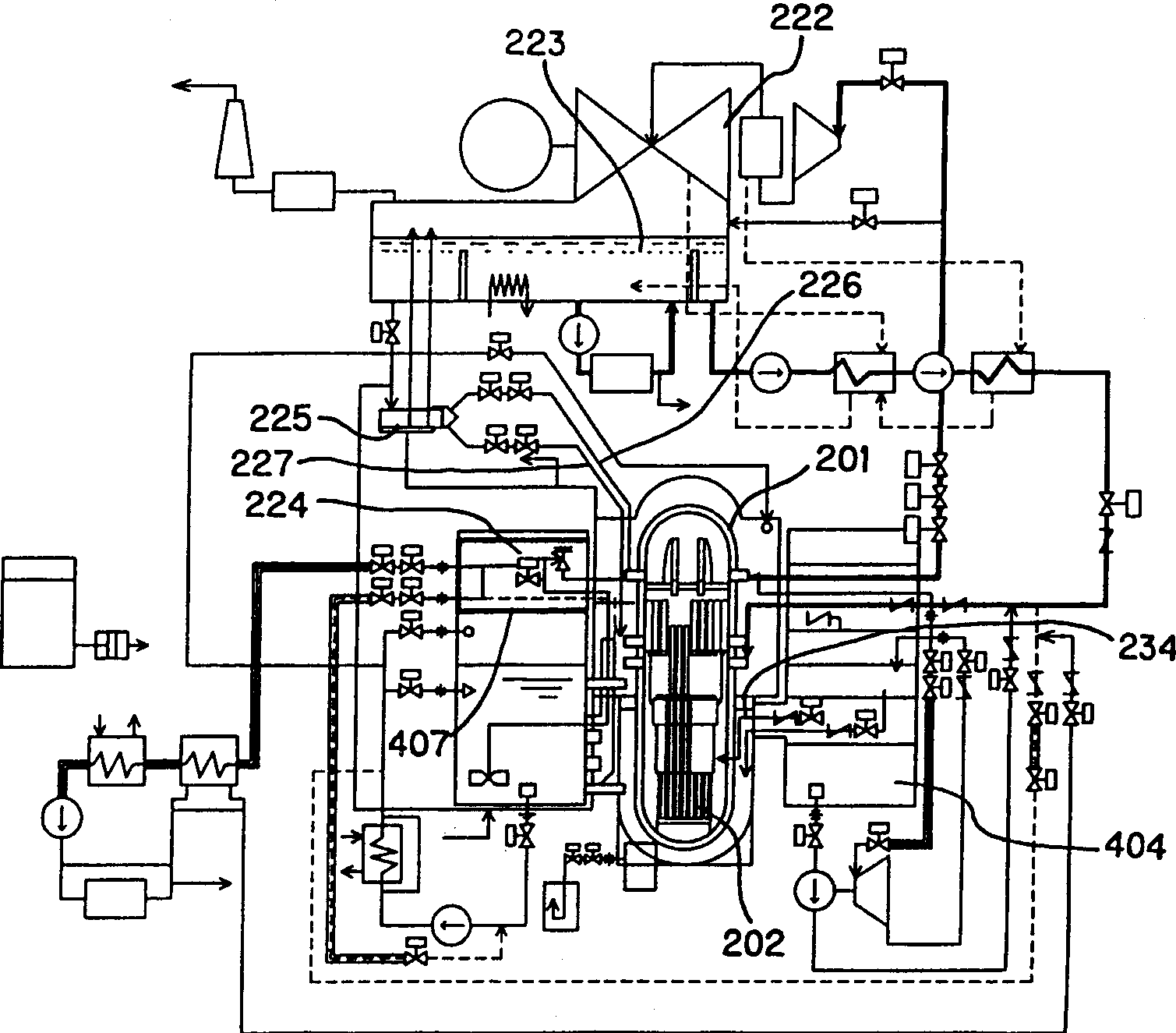

[0091] Refer below Figure 1 to Figure 14 An embodiment of the boiling water type atomic power plant according to the present invention will be described.

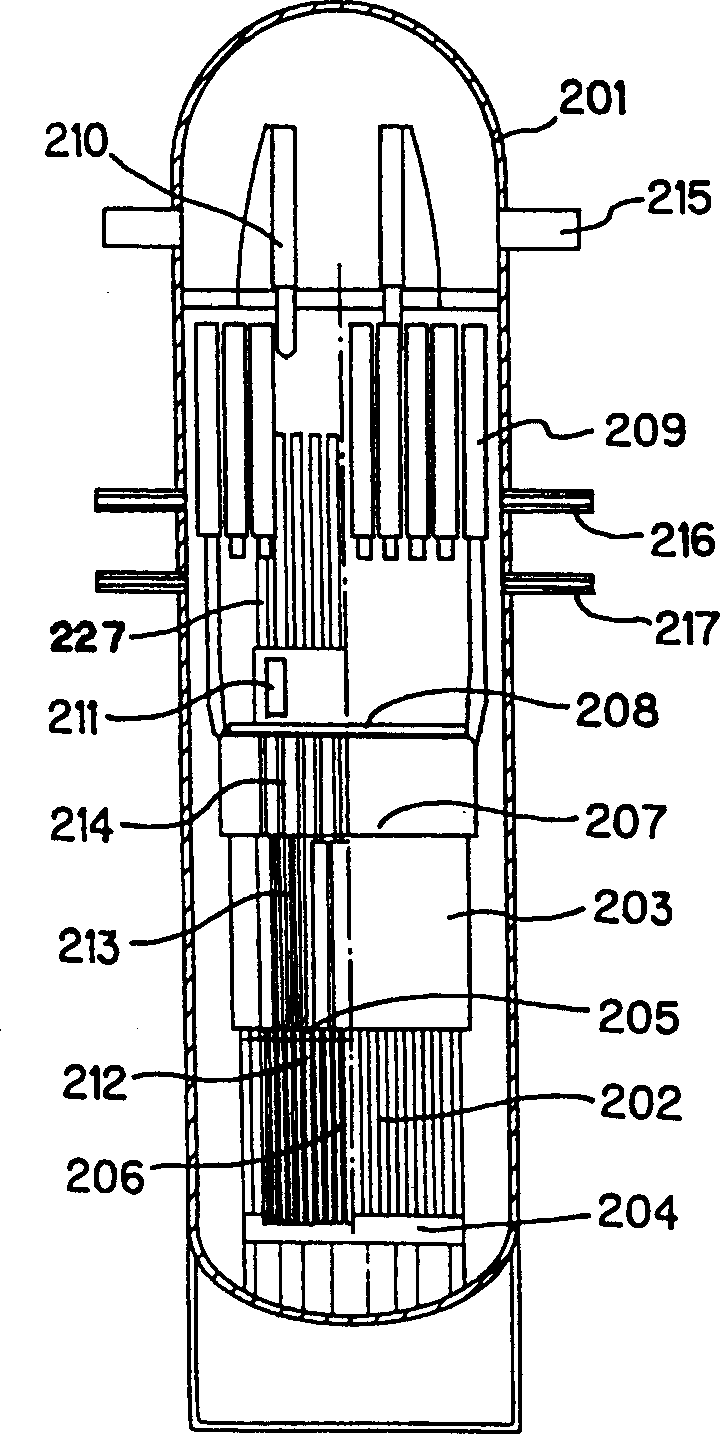

[0092] figure 1 It is a cross-sectional view showing a schematic configuration of a nuclear reactor pressure vessel. Such as figure 1 As shown, in this embodiment, a reactor core 202 is provided at the lowest end position in the nuclear reactor pressure vessel 201 . That is, a reactor core support plate 204 is provided near the bottom of the nuclear reactor pressure vessel 201, and a plurality of fuel assemblies 206 arranged in a square grid are vertically supported on the reactor core support plate 204. The upper ends of the fuel assemblies 206 are formed by The upper grid plate 205 is fixed, thereby constituting the reactor core 202 .

[0093] The control rods 212 are cross-shaped control rods, are regularly arranged corresponding to the four fuel assemblies 206 , and are inserted from the upper part of the reactor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com