Method for drawing out bean and prop of workshop without stopping production

A plant and conditional technology, applied in building maintenance, industrial construction, construction, etc., can solve problems such as crane operation, achieve the effect of solving production stop problems, saving production time, and considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

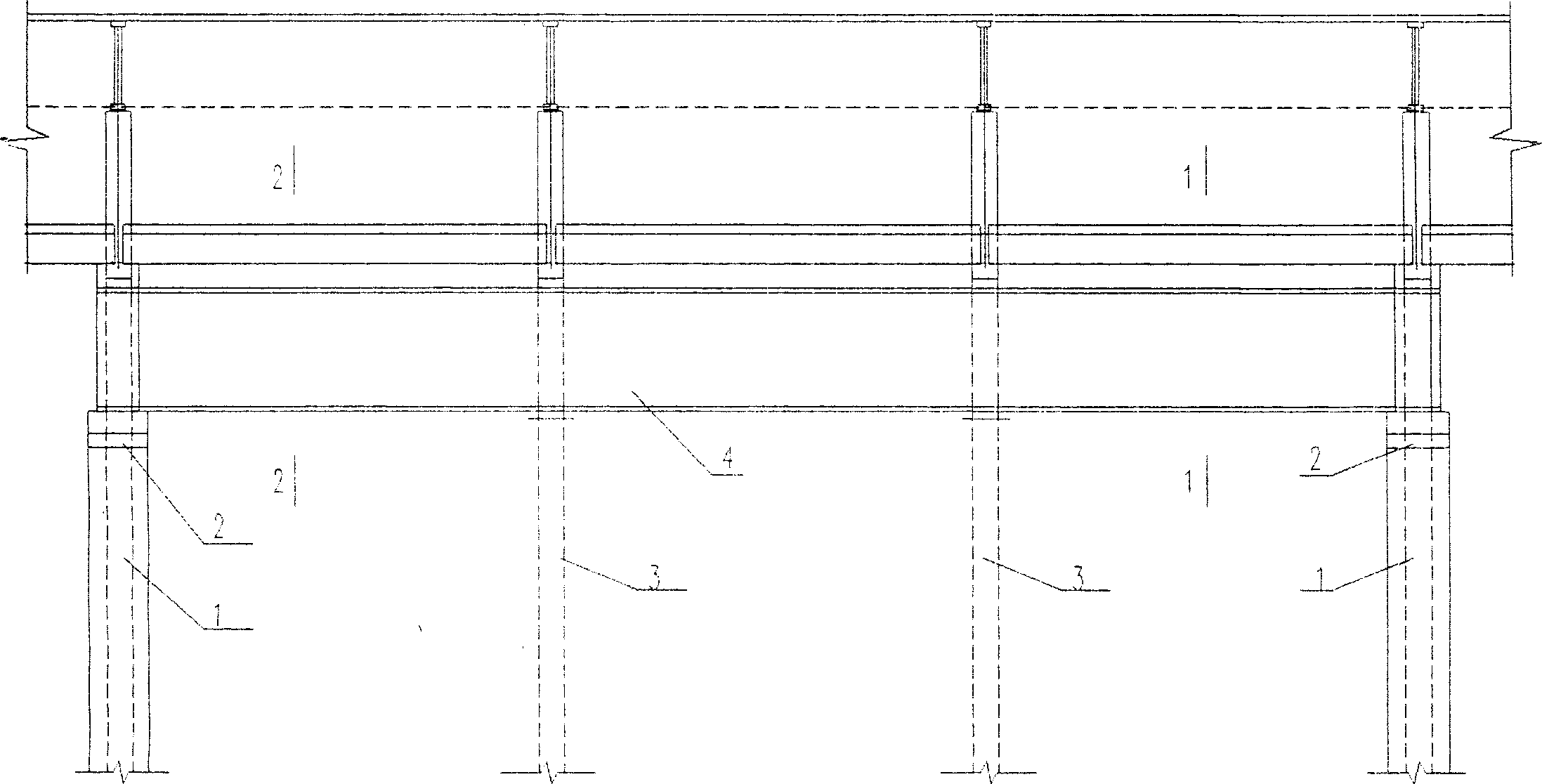

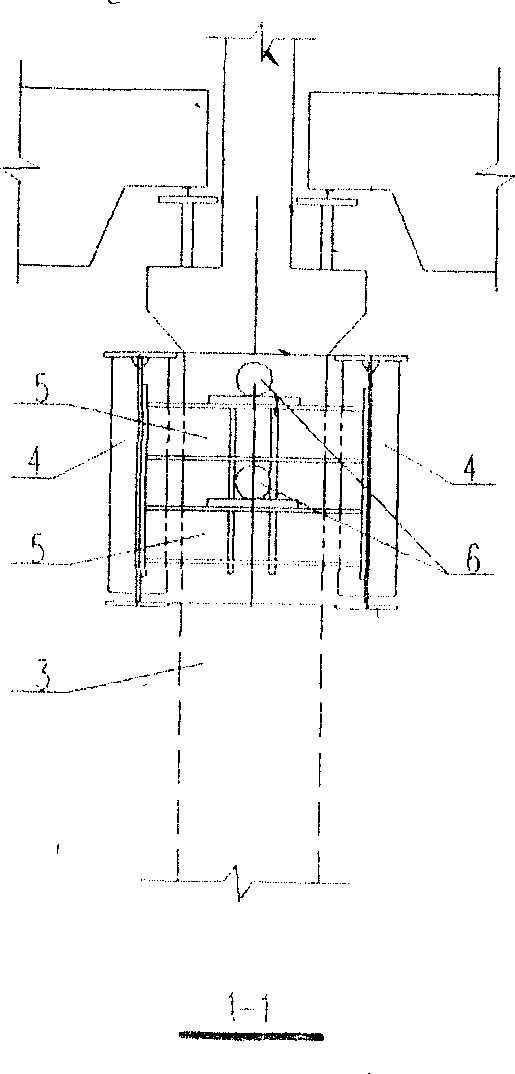

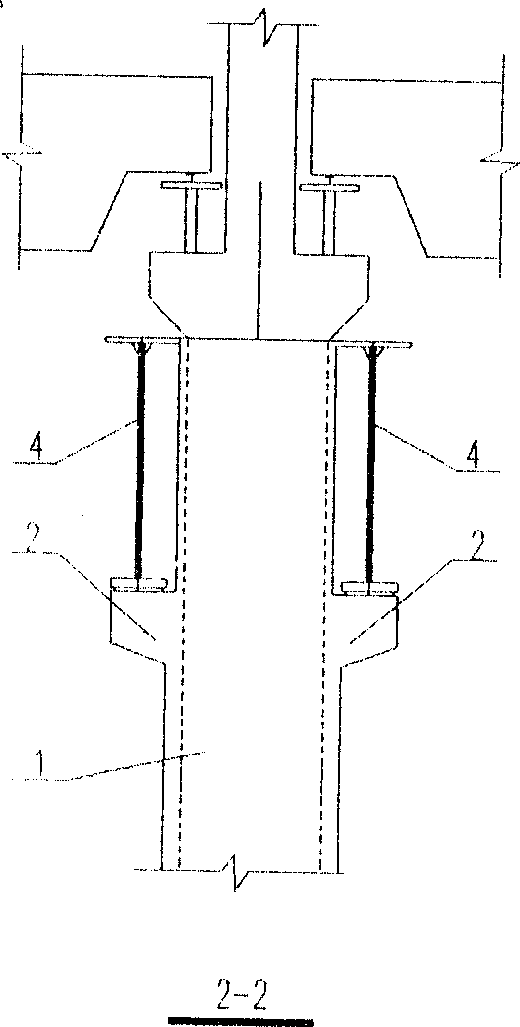

[0014] The existing technology is to use steel joists to support the roof system of the factory building. The crane beam and walkway slab system must be dismantled, and the steel crane beam and walkway slab system with the same length as the joist must be rebuilt and installed. Therefore, it takes several months to stop production. . The method of the present invention is to use the lifting beam to directly lift the crane beam, the walkway plate and the roof system above the part of the factory building where the columns are to be extracted. To this end, the supporting bent columns at both ends (that is, the supporting columns at both ends of the steel lifting beam) and the column foundation are first reinforced, and corbel bosses are added at appropriate positions below the crane beams on both sides of the column. At the same time, two single-piece lifting beams (two "I"-shaped welded steel beams) are produced. After the strength of the reinforced part of the supporting bent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com