Feed pump

A feed pump and oil technology, applied in the direction of pumps, pump components, cross-flow pumps, etc., can solve the problems of reducing the working efficiency of the feed pump, strong noise, etc., to achieve simple rotation ability and axial movement ability, low click noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Description of preferred embodiments

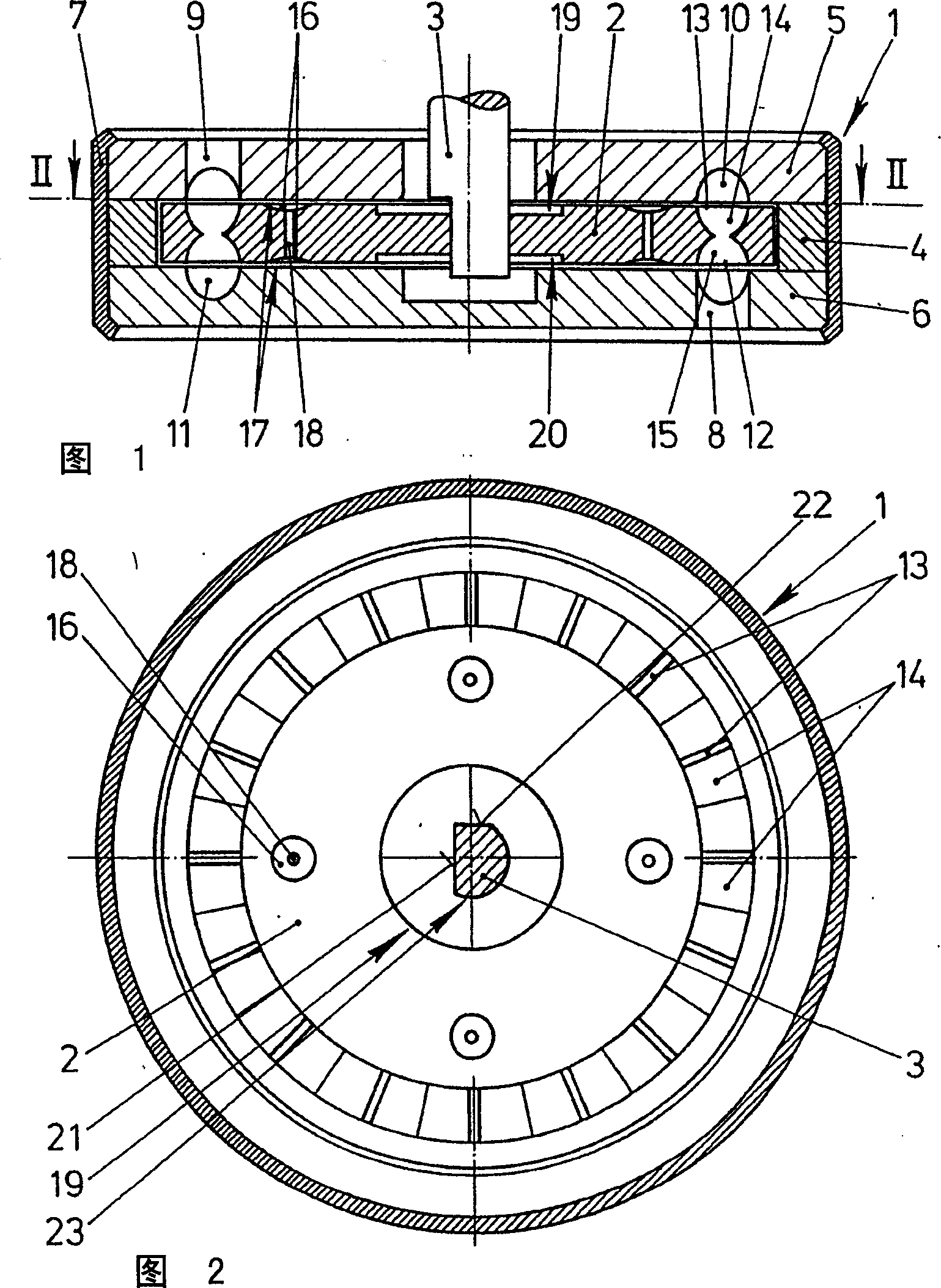

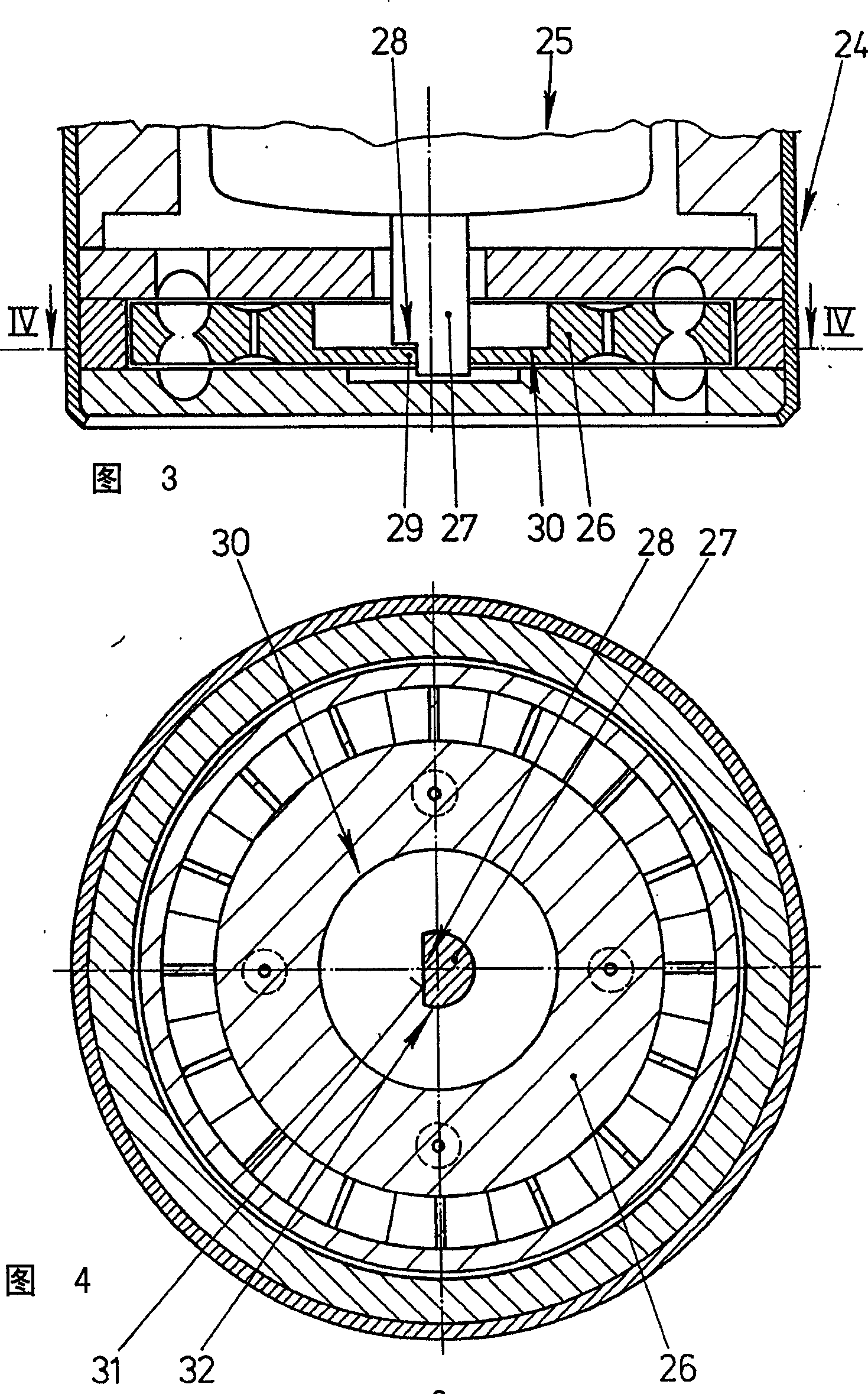

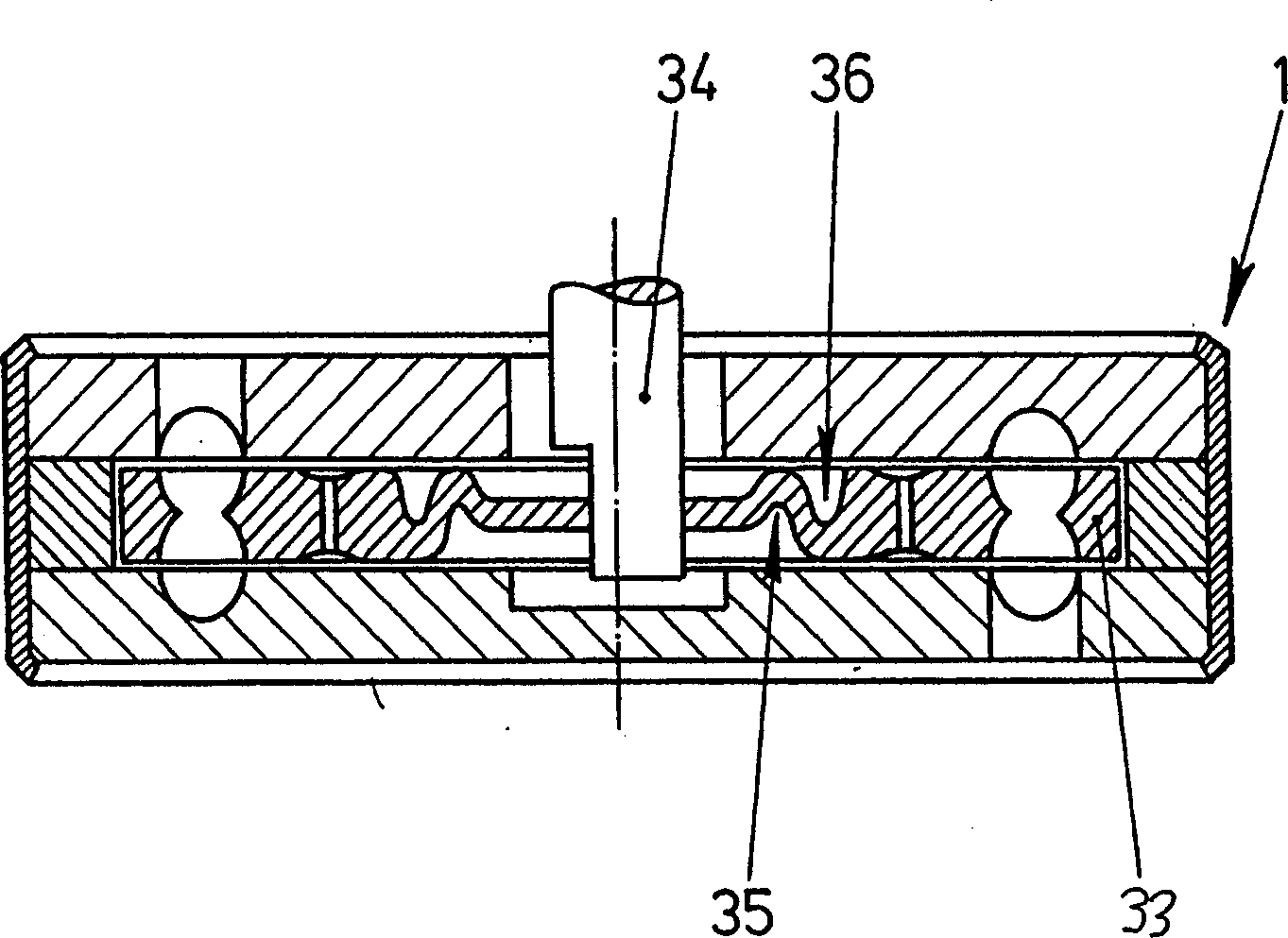

[0021] FIG. 1 shows a sectional view of a feed pump according to the invention, which is designed as a side channel pump and has an impeller 2 rotatable in a housing 1 . The impeller 2 is mounted on a drive shaft 3 fixedly with respect to the direction of rotation but slightly displaceable axially. The shaft 3 can be designed, for example, as the shaft of an electric motor (not shown). The housing 1 has two shell parts 5, 6 kept at a distance from each other by a ring 4 and a thin metal strip 7 rolled up on the edges of the shell parts 5, 6 in order to pretension the shell parts 5, 6 Tight on circle 4. An inlet flow channel 8 is arranged in one of the shell parts 6 , while the other shell part 5 has an outlet flow channel 9 . The inlet flow channel 8 and the outlet flow channel 9 are in each case connected to partial annular flow channels 10 , 11 . The impeller 2 has vane chambers 14 , 15 delimited by guide vanes 12 , 13 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com