Pneuamtic suction pipe connector for refuse recovering apparatus

A technology for recycling equipment and coupling devices, which can be used in suction hoses, cleaning equipment, mechanical equipment, etc., and can solve problems such as disconnection, damage to related parts, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

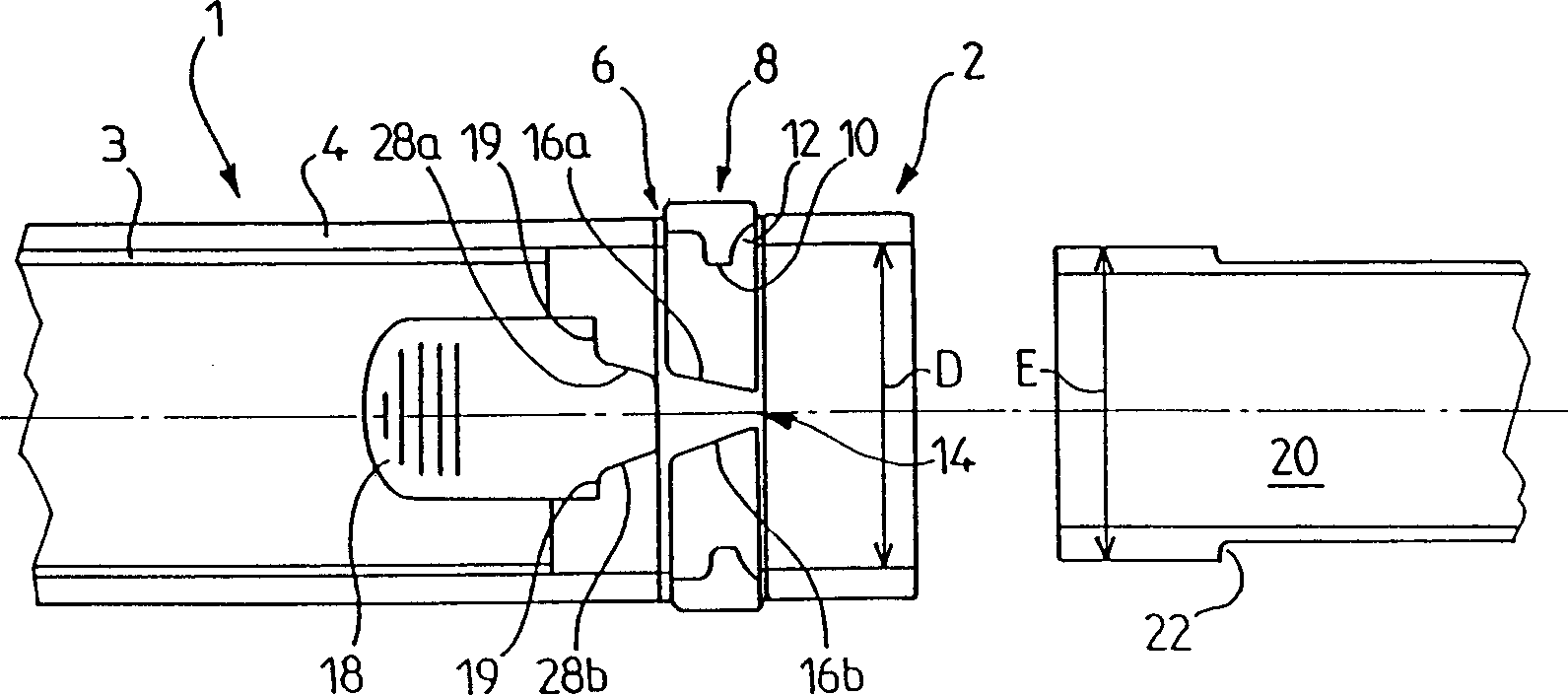

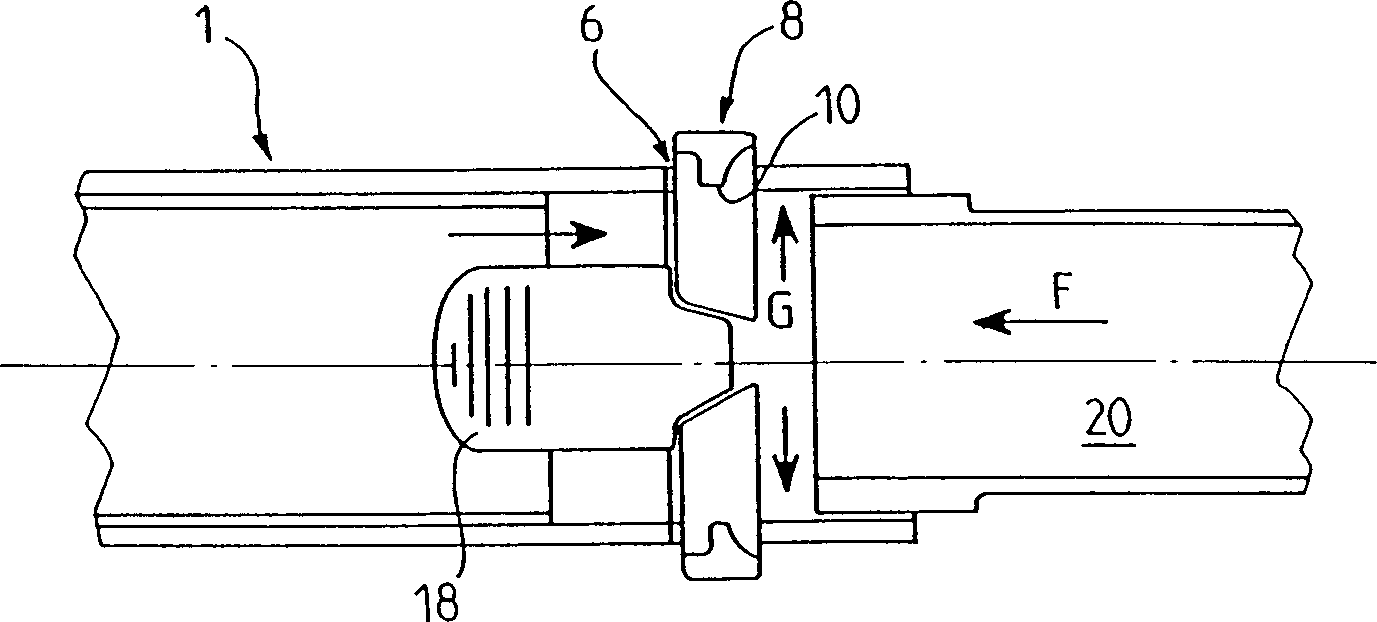

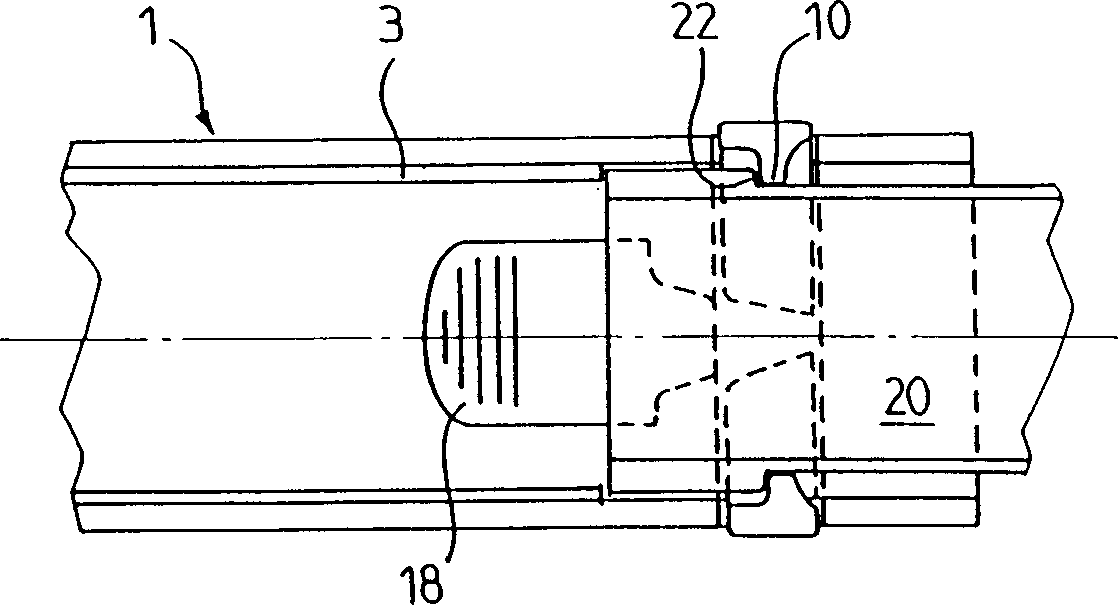

[0031] According to the present invention, if figure 1 In the embodiment shown, the tube 20 constitutes a part intended to be connected to another part 1 with an end 2 .

[0032] According to the embodiment shown, part 1 is a sleeve 4 mounted on pipe 3 , protruding from pipe 3 , the inner diameter D of which is slightly greater than the outer diameter E of pipe 20 . This feature enables the insertion of the tube 20 in the end 2 of the part 1 .

[0033] According to the invention, part 1 has a split elastic ring 8 which has the shape and function of a circlip. Thus, said elastic ring is split at 14 , which ring is arranged in the groove 6 of the end 2 of the part 1 . Advantageously, the ring has pins 10 towards the inside of the ring, as Figure 4 shown in .

[0034] According to the embodiment shown, the ring has a lug 11 which prevents rotation when the two parts on either side of the opening 14 are opened. This lug is not indispensable, especially if the symmetrical act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com