Method and equipment for producing bidirectional stretching plastic film

A plastic film, biaxial stretching technology, applied in the field of plastic processing, can solve the problems of high product cost, high price, complicated process, etc., and achieve the effect of simplifying the production process and reducing the price of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

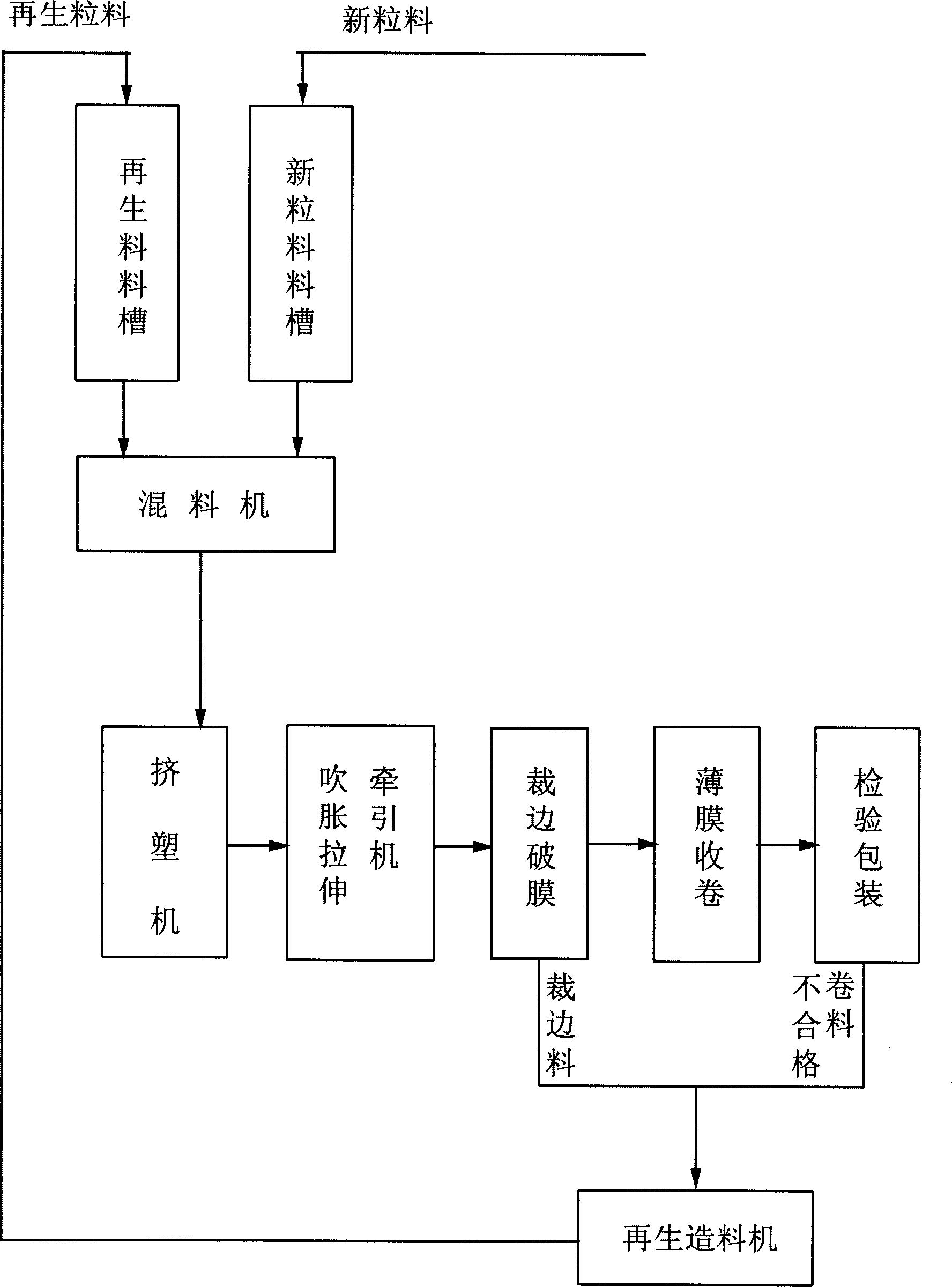

Method used

Image

Examples

Embodiment Construction

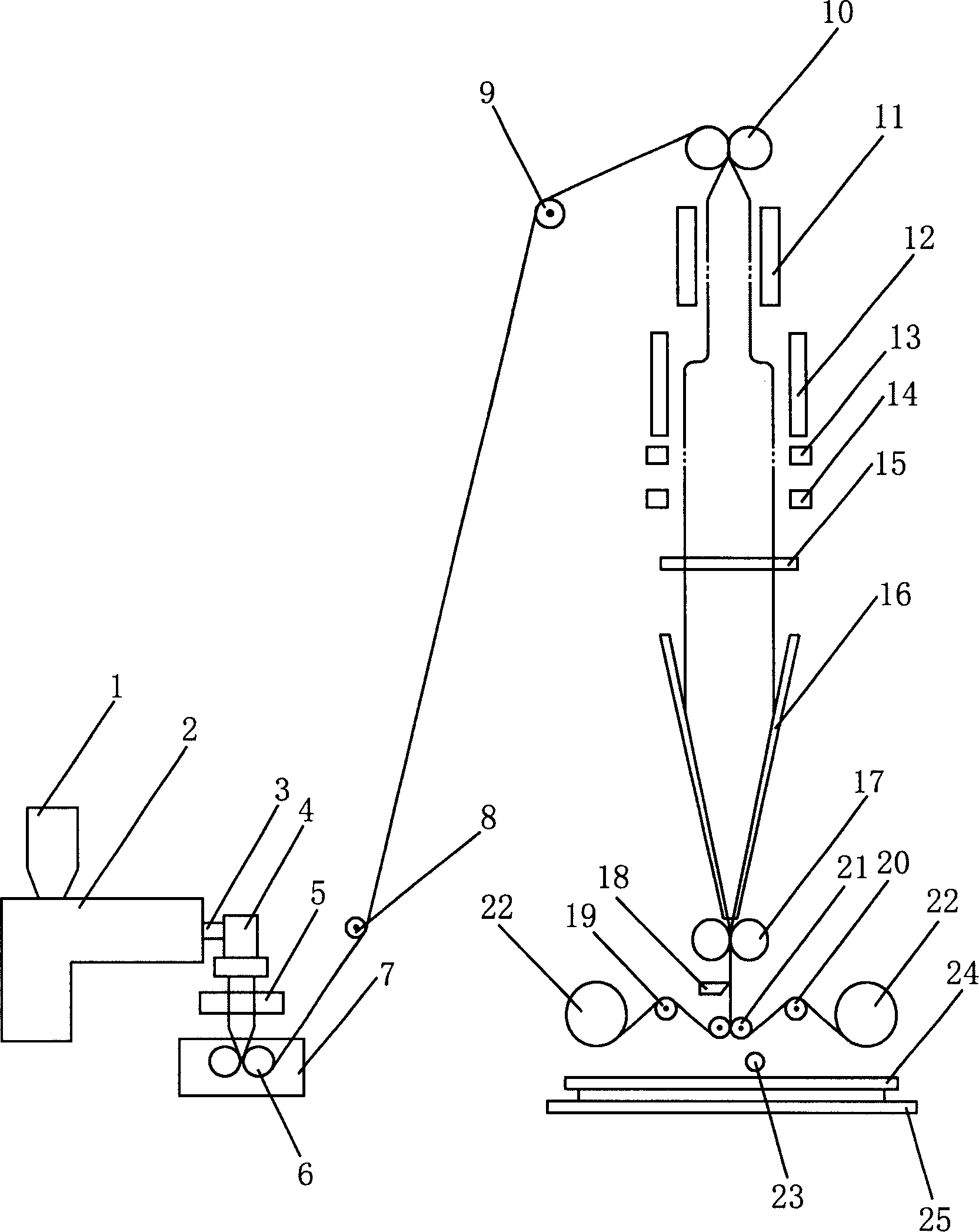

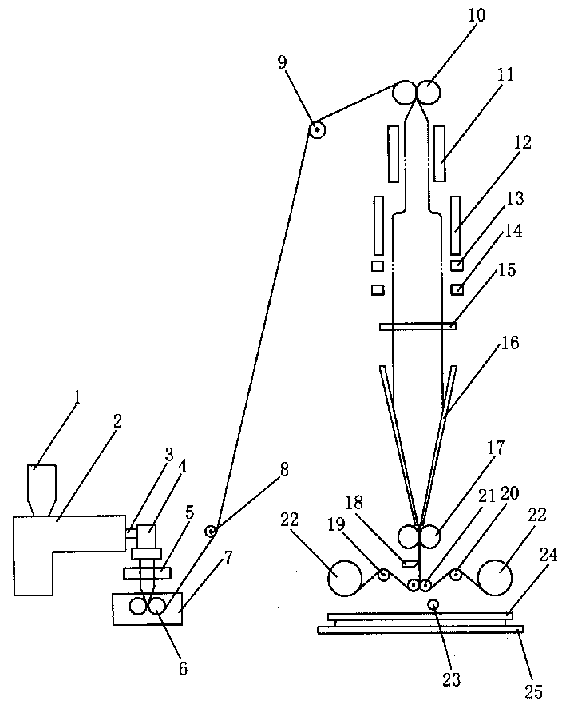

[0012] The equipment for producing biaxially stretched plastic films provided by the present invention is designed in this way: it includes a film extruding device, a stretching traction device, a cooling device, a platform winding device and an electrical control device, etc., and is characterized in that: Biaxial stretching rotary heating devices 11 and 12 for film biaxial stretching are arranged on the upper part of the pulling device.

[0013] Below in conjunction with accompanying drawing, the method for biaxially stretched plastic film provided by the present invention is further described:

[0014] After the blank enters from the hopper 1, it is melted and extruded by the extruder 2, and the film head adapter 3 introduces the melted and kneaded plastic of the extruder into the bubble tube die 4, and the bubble tube die 4 extrudes the molten plastic For the membrane tubular. The plastic film tube is led out from the die head by the first clamp roller 6, and the thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com