Universal hollow-structure great-moment ring piezoelectric ultrasonic motor

A technology of ultrasonic motor and high torque, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motor, generator/motor, electrical components, etc., can solve the problems of lack of versatility and high torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

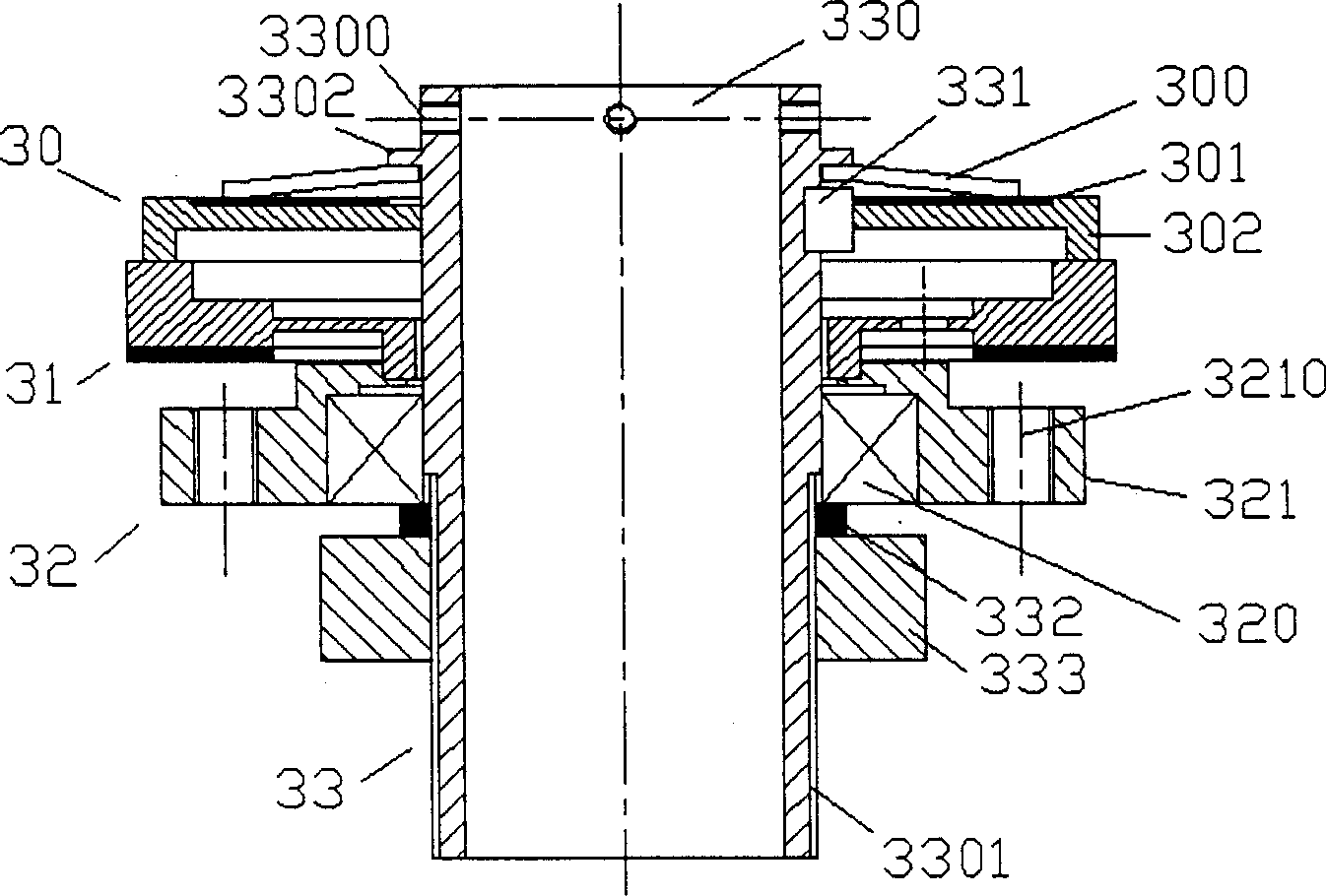

[0013] please see Figure 3 ~ Figure 5 .

[0014] image 3 Is the general structure of this embodiment. It consists of a rotor part 30 , a stator part 31 , a base part 32 and a shaft part 33 . Wherein, the stator part 31 is composed of a metal ring 313 with comb-shaped driving teeth 310 and an annular piezoelectric ceramic sheet 314, and the annular piezoelectric ceramic sheet 314 is bonded to the bottom of the metal ring 313 by epoxy resin glue; the base part 32 has a base 321 with a fixed screw hole 3210, and its inner wall has a standard ball bearing 320 for positioning the central shaft 33; the rotor 30 is made up of a disc spring 300, a rubber sheet 301 and a metal ring sheet 302, and the rubber sheet 301 and the metal ring piece 302 are bonded with epoxy resin, and under the action of the disc spring 300, the metal ring piece 302 closely cooperates with the stator driving teeth 310, so that the rotor part 30 and the stator part 31 are in close contact; the shaft 33 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com