Great-moment oscillating piezoelectric ultrasonic motor

A technology of ultrasonic motor and high torque, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve problems such as limited applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

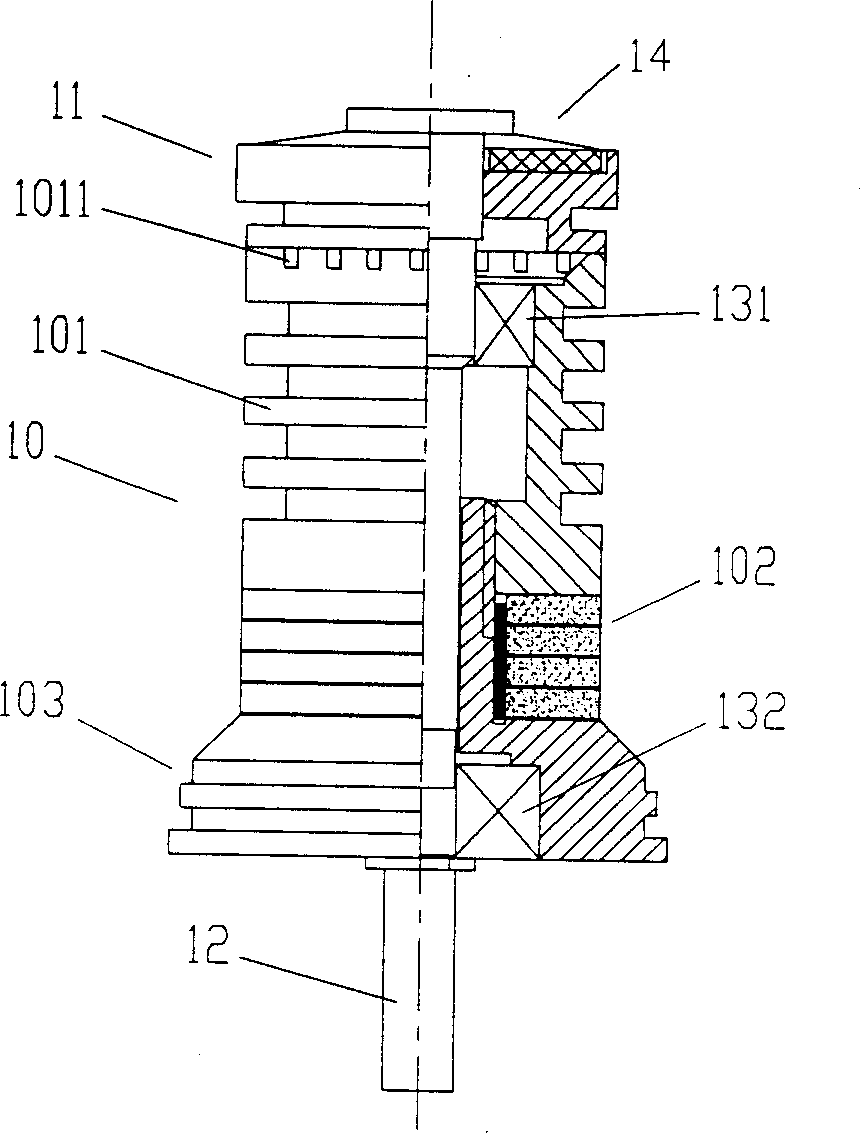

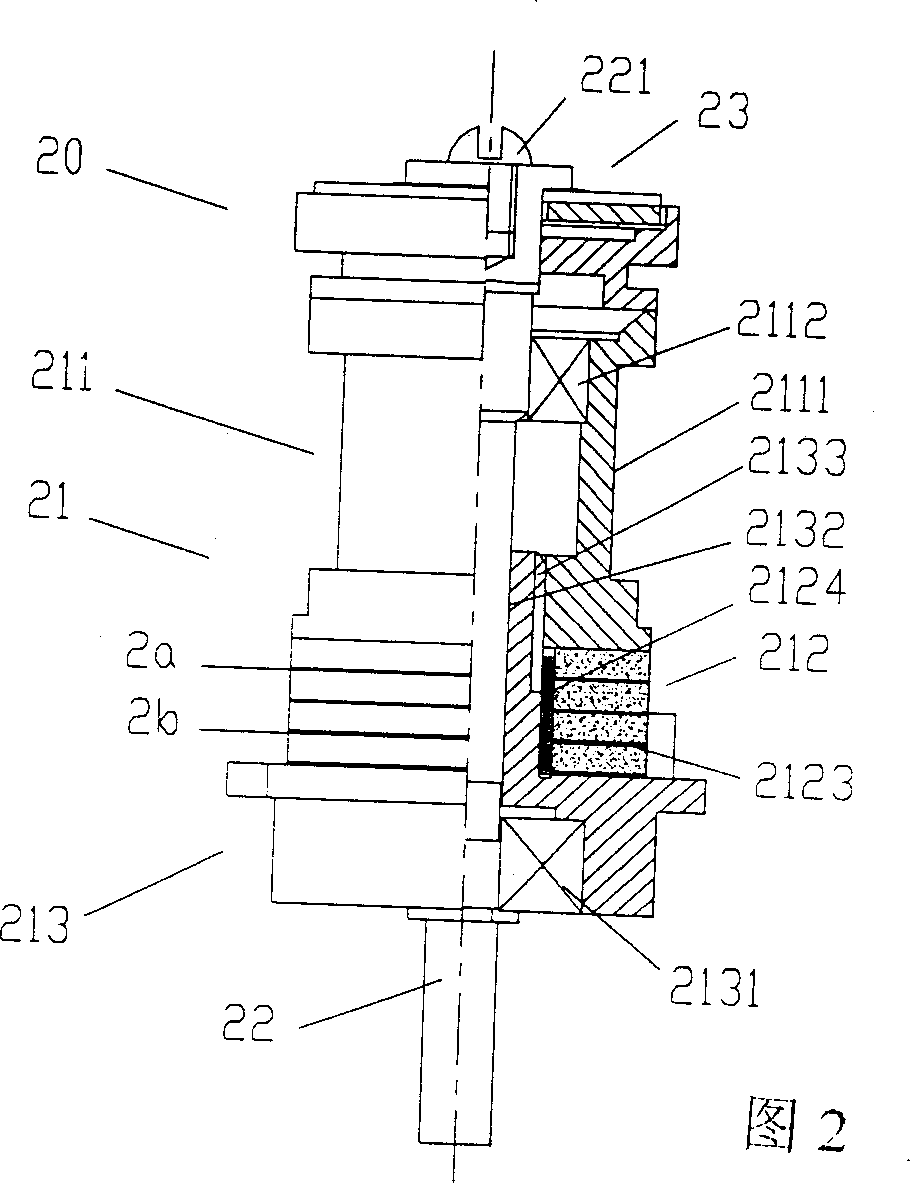

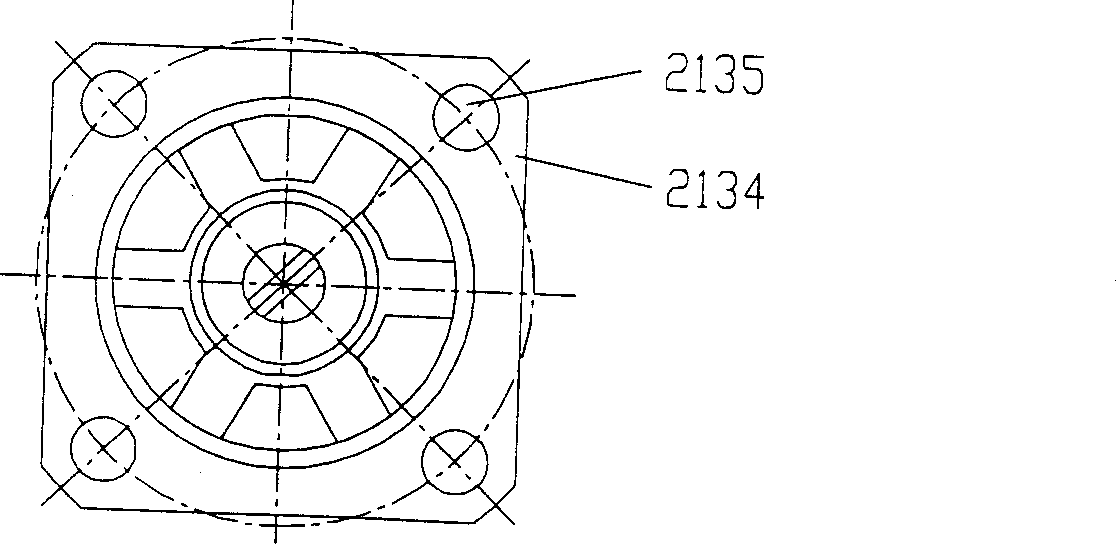

[0015] Please see Figure 2. The motor of the present invention is composed of a stator 21 , a rotor 20 , a central shaft 22 and a pressure mechanism 23 . Among them, the stator 21 is composed of an upper matching block 211 with a stepped structure shape 2111 of the ultrasonic horn type, and the two sides of the lower end are milled into a cake shape to facilitate the application of pre-tightening force, and a lower matching block with a square flange type base 2134 213 and four piezoceramic rings 212 tightly clamped in the middle by the inner thread of the upper matching block 211 and the screw structure 2133 of the lower matching block 213, the piezoelectric ceramic rings 212 are formed between the screw 2133 and the screw hole The clamping force of the ceramic sheet 212 is fixed (also can be bonded with epoxy resin glue). There is a screw 221 at the end of the central shaft 22 close to the rotor 20, so that the position of the central shaft 22 can be manually adjusted with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com