Control strategy of switch magnetic resistance driving system

A technology of switched reluctance drive and switching device, which is applied in the direction of motor generator control, AC motor control, electronic commutation motor control, etc., and can solve the problem of reducing the voltage rating of DC line capacitors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

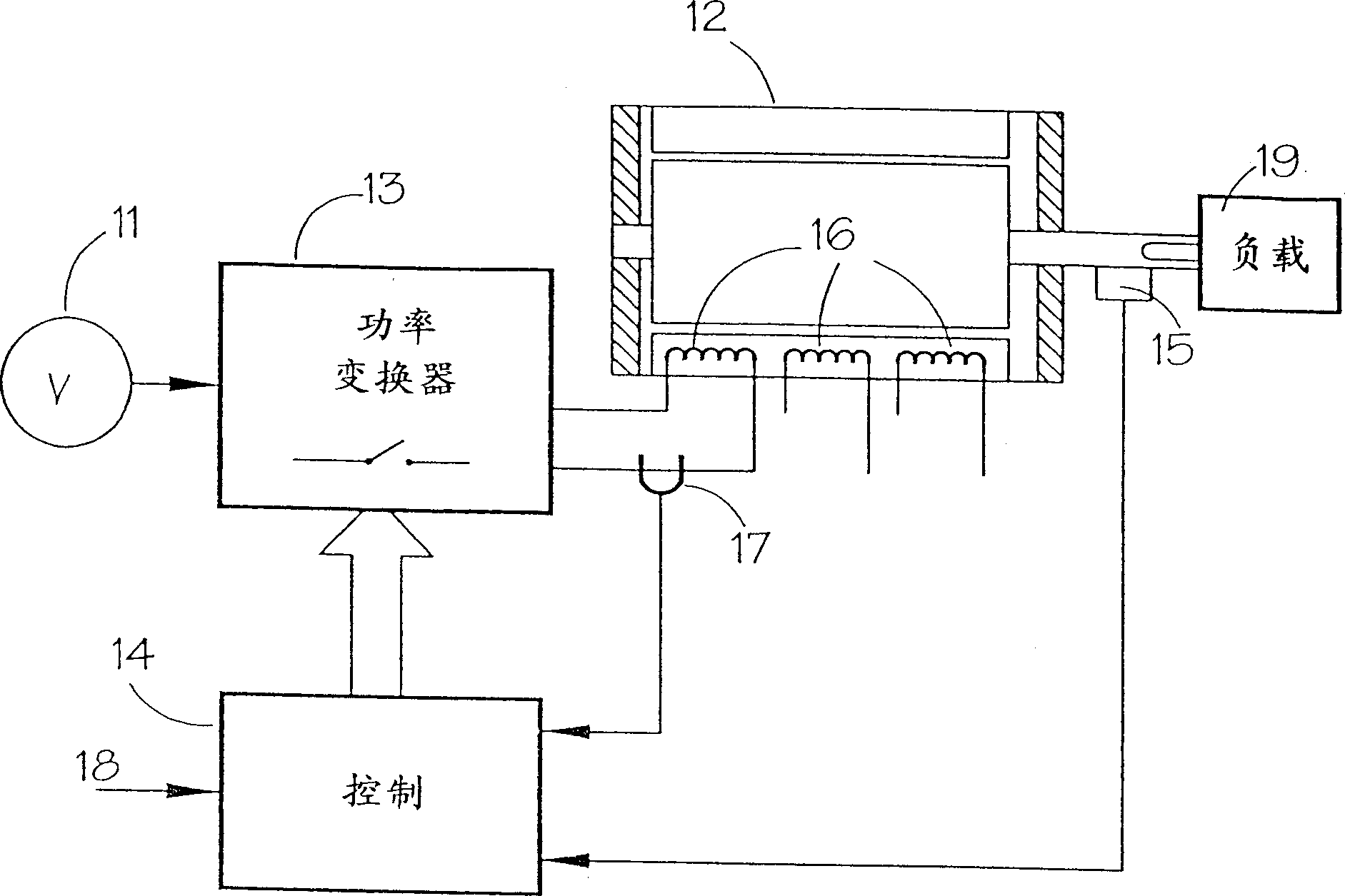

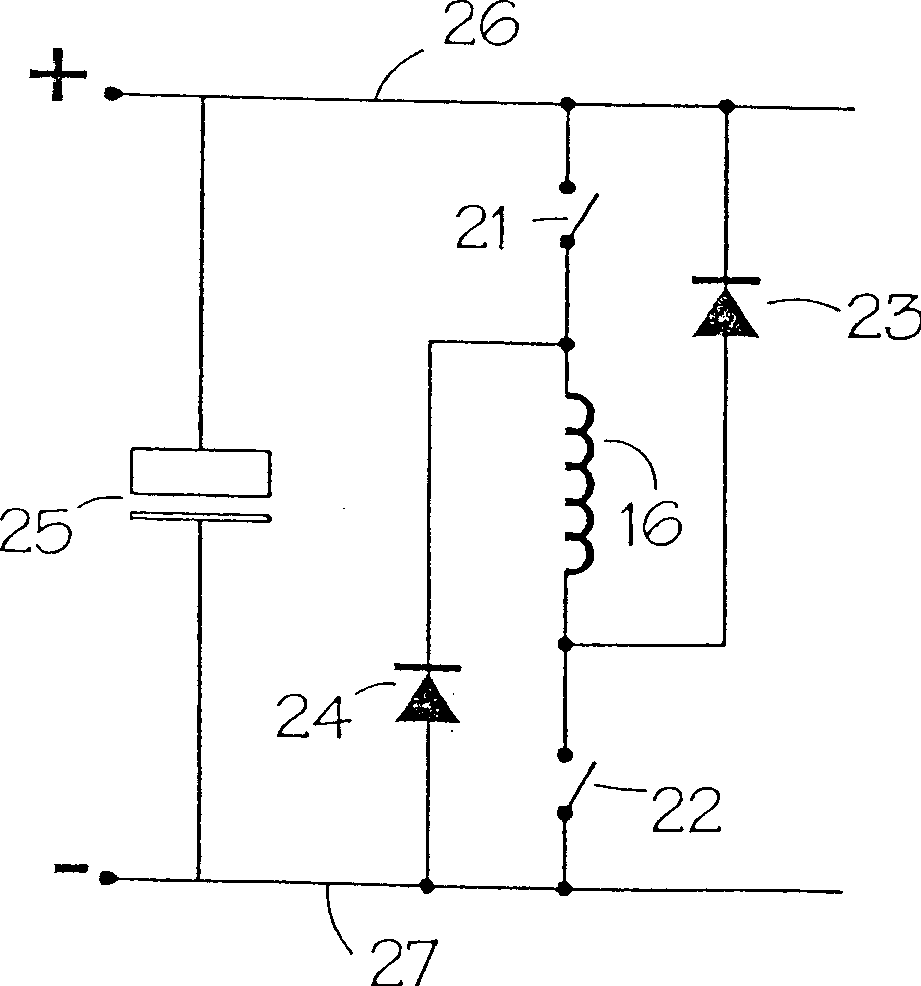

[0026] The invention can be implemented by a first embodiment in a drive system as shown in FIG. 1 with several switching circuits for each phase as shown in FIG. 2 . According to the invention, the control strategy is adapted to use a dead-running configuration of the switching circuit programmed by the controller 14 .

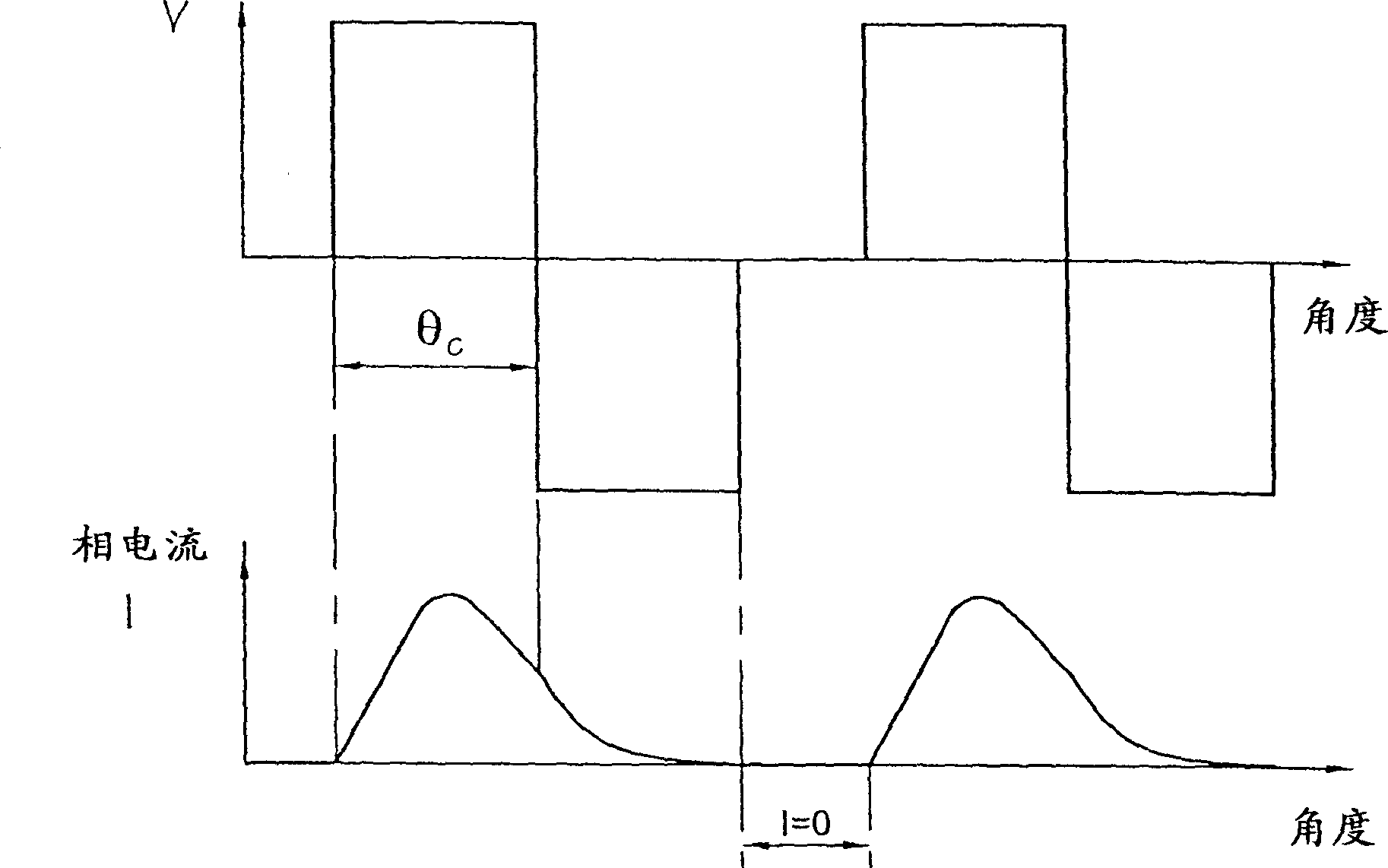

[0027]FIG. 5(a) shows the voltage waveform at the terminal of DC line capacitor 25 (ie, the DC line voltage) when one phase of the circuit of FIG. 2 is operated in a conventional manner to produce the phase current waveform of FIG. 3(a). The graph is drawn under ideal conditions where the voltage source 11 and the DC link capacitor have a minimum inductance. It can be seen that the DC link voltage is virtually constant, with short term very small spikes at the point where the phase is disconnected.

[0028] But in a real circuit, the source has resistance and inductance, and the capacitor and its connecting wires will also have some additional inductance. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com