Ultraviolet laser method for improving dyeing peformance of cationic dye on polyester fabric

A cationic dye, ultraviolet laser technology, applied in the field of invention of changing the dyeing properties of polyester textiles, can solve the problems of restricted use and the inability of ordinary polyester fibers to be dyed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following examples will help understand the present invention, but do not limit the content of the present invention.

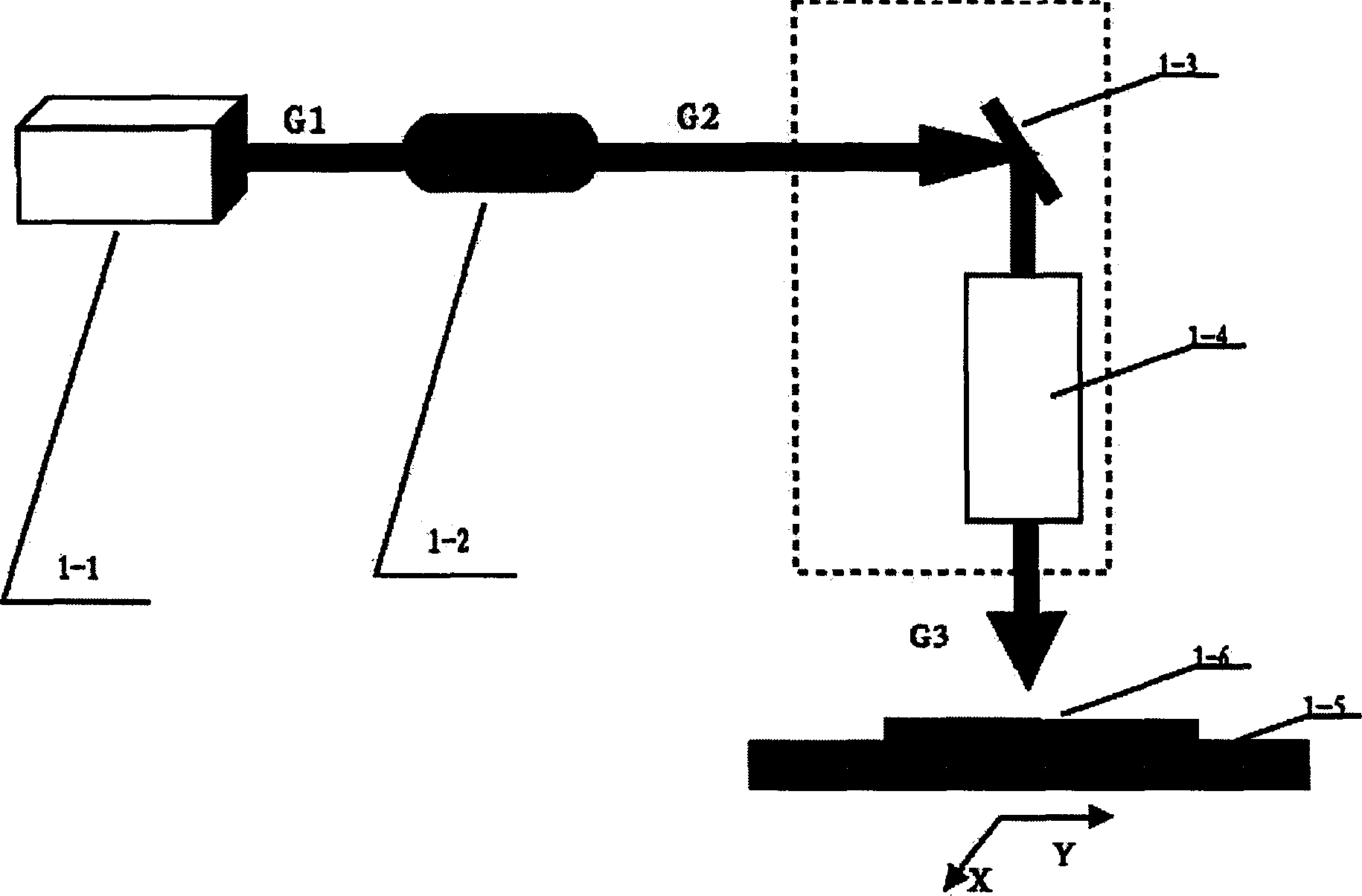

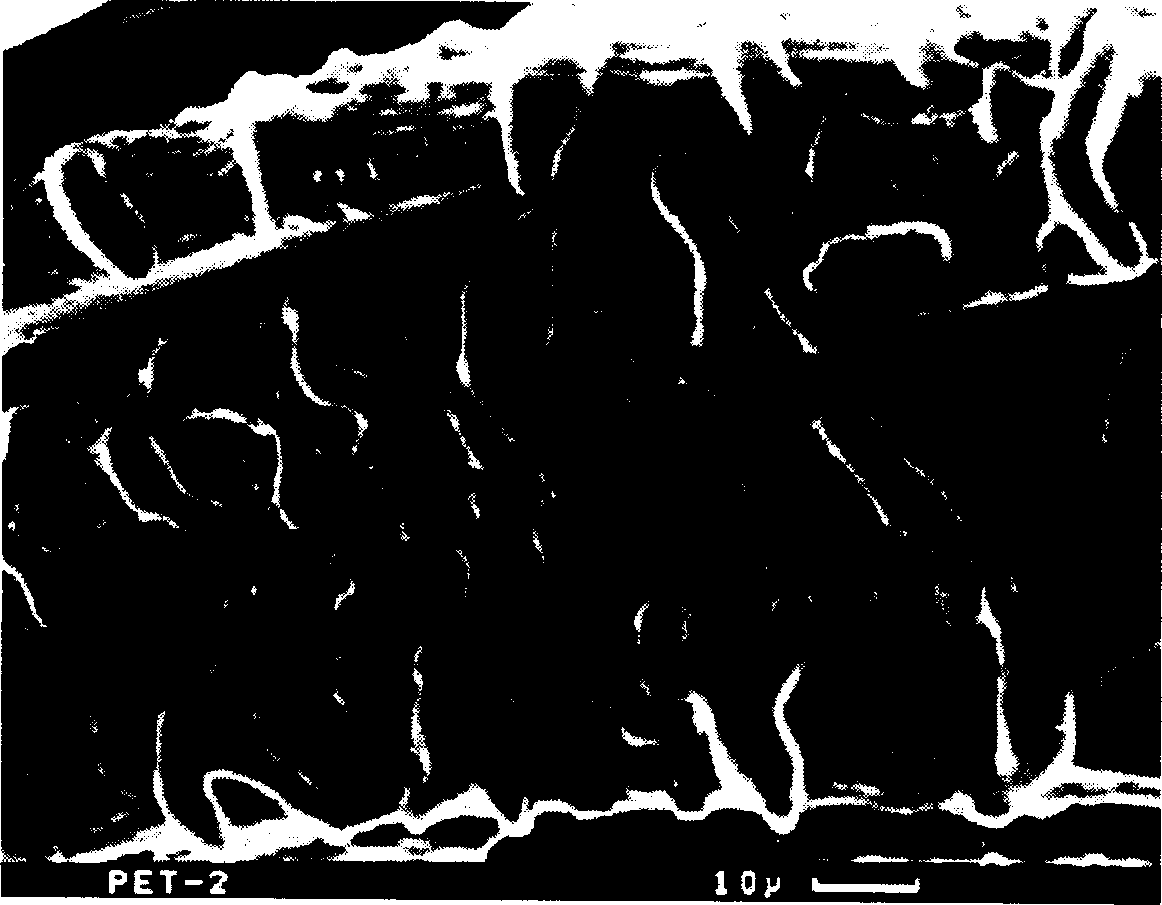

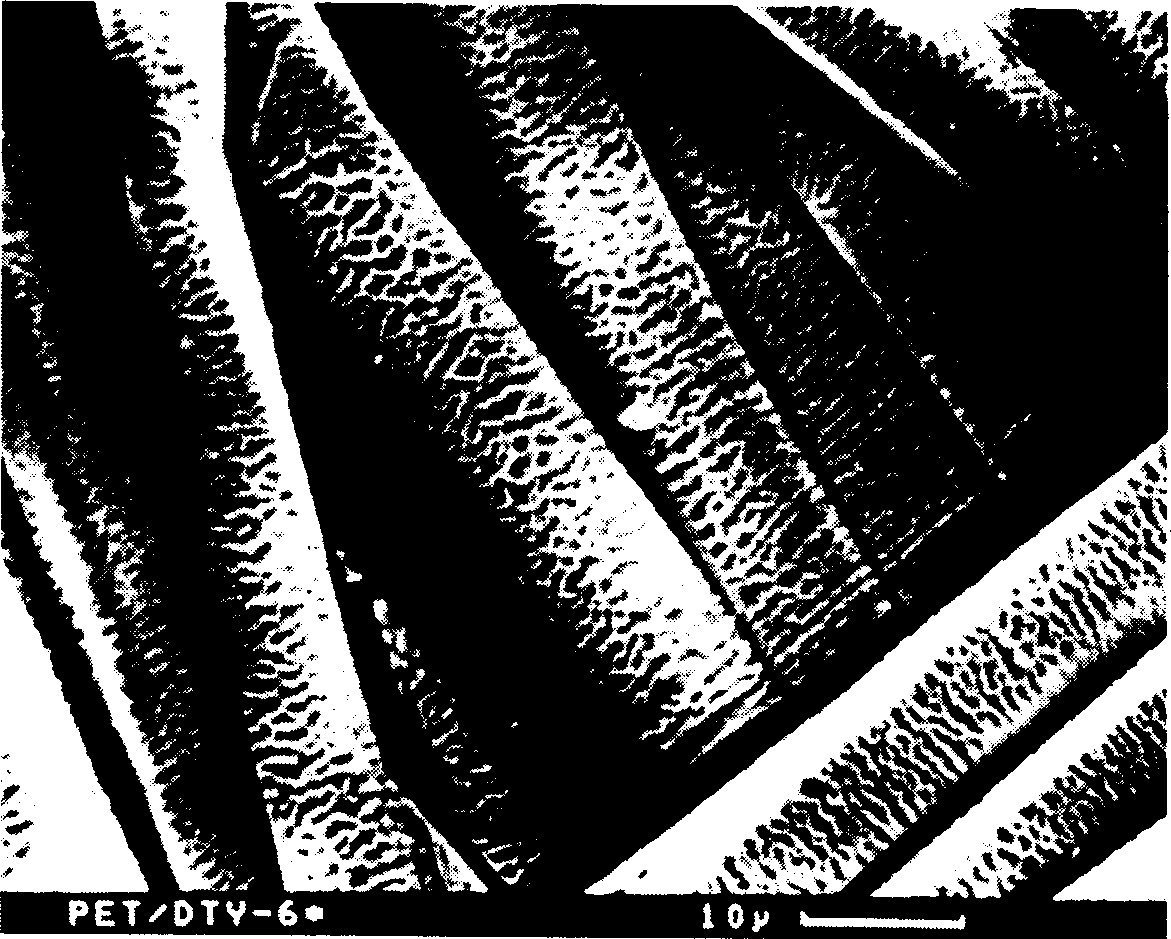

[0014] First, the polyester fabric is irradiated with ultraviolet laser, the laser wavelength used is λ 1 And λ 2 The excimer laser has a pulse width of 20-40ns. Processing device such as figure 1 , The energy density of the laser is 50~150mJ / cm 2 , The size of the laser spot is 4mm×6mm, the polyester fabric is made of DTY, the processing area is 12cm×6cm, and the number of exposures is 5 to 10 times. The rotation speed of the motor used in the work platform is 200 rpm, and the entire processing area is scanned sequentially by the translation of the work platform. After being irradiated by excimer ultraviolet lasers of different wavelengths, the surface of the polyester fabric has regular undulating structures, which form a periodic undulating structure perpendicular to the fiber axis. picture 2-1 with Figure 2-2 . Irradiation of different laser wave...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com