Wafer cleaner

A wafer cleaning and wafer technology, which is applied to cleaning methods and utensils, cleaning methods using liquids, electrical components, etc., and can solve the problems of waste of chemical cleaning agents, poor device effect, and inability to temporarily store chemical cleaning agents on the surface of wafers, etc. , to avoid rapid dispersion and maintain the effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Without limiting the spirit and scope of application of the present invention, the implementation of the present invention is described below with an embodiment; those skilled in the art, after understanding the spirit of the present invention, can apply this method to various On the chemical cleaning device, to eliminate the disadvantages of poor cleaning effect and waste of too much chemical cleaning agent when traditionally relying on centrifugal force alone for chemical cleaning, the application of the present invention should not be limited to the embodiments described below .

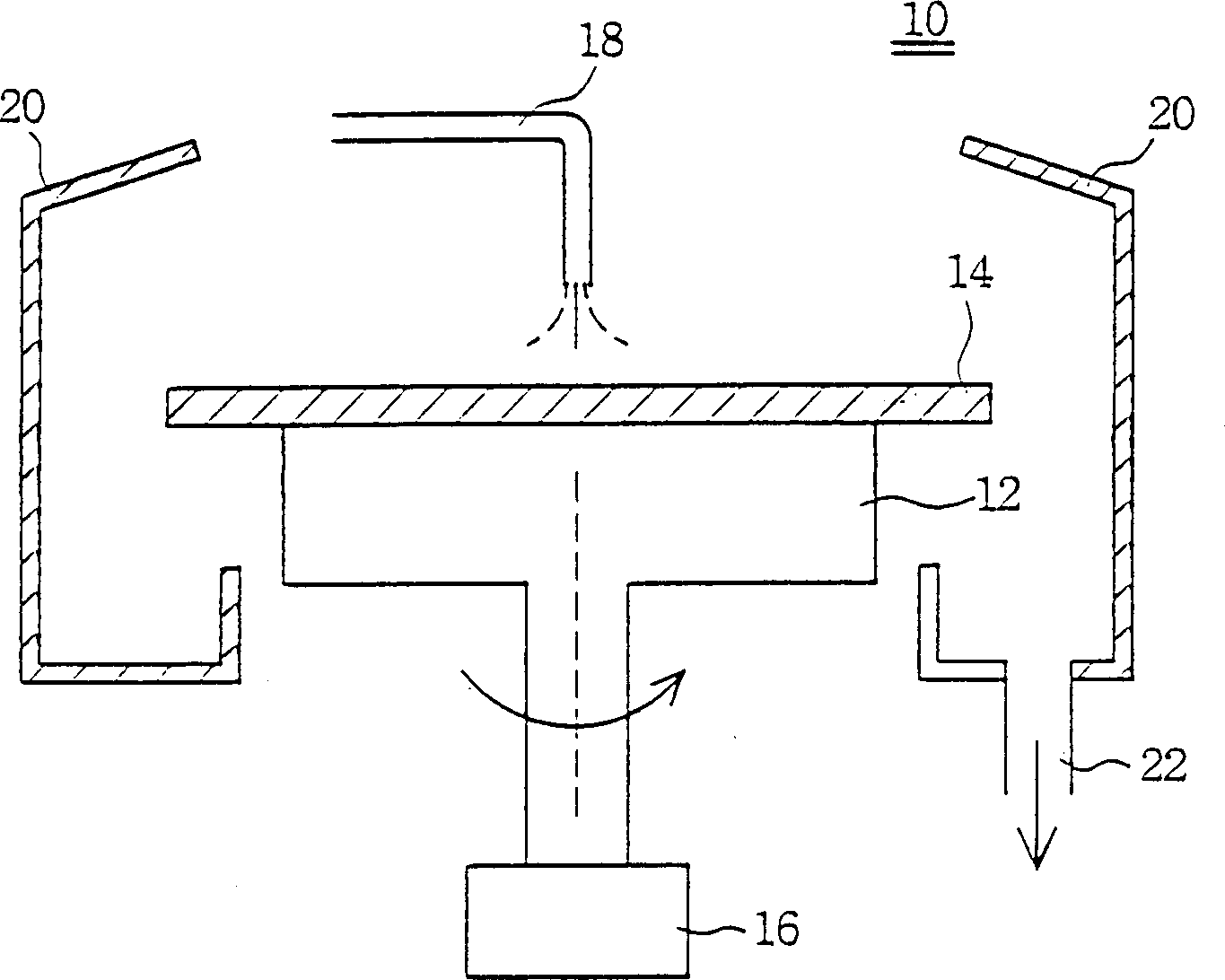

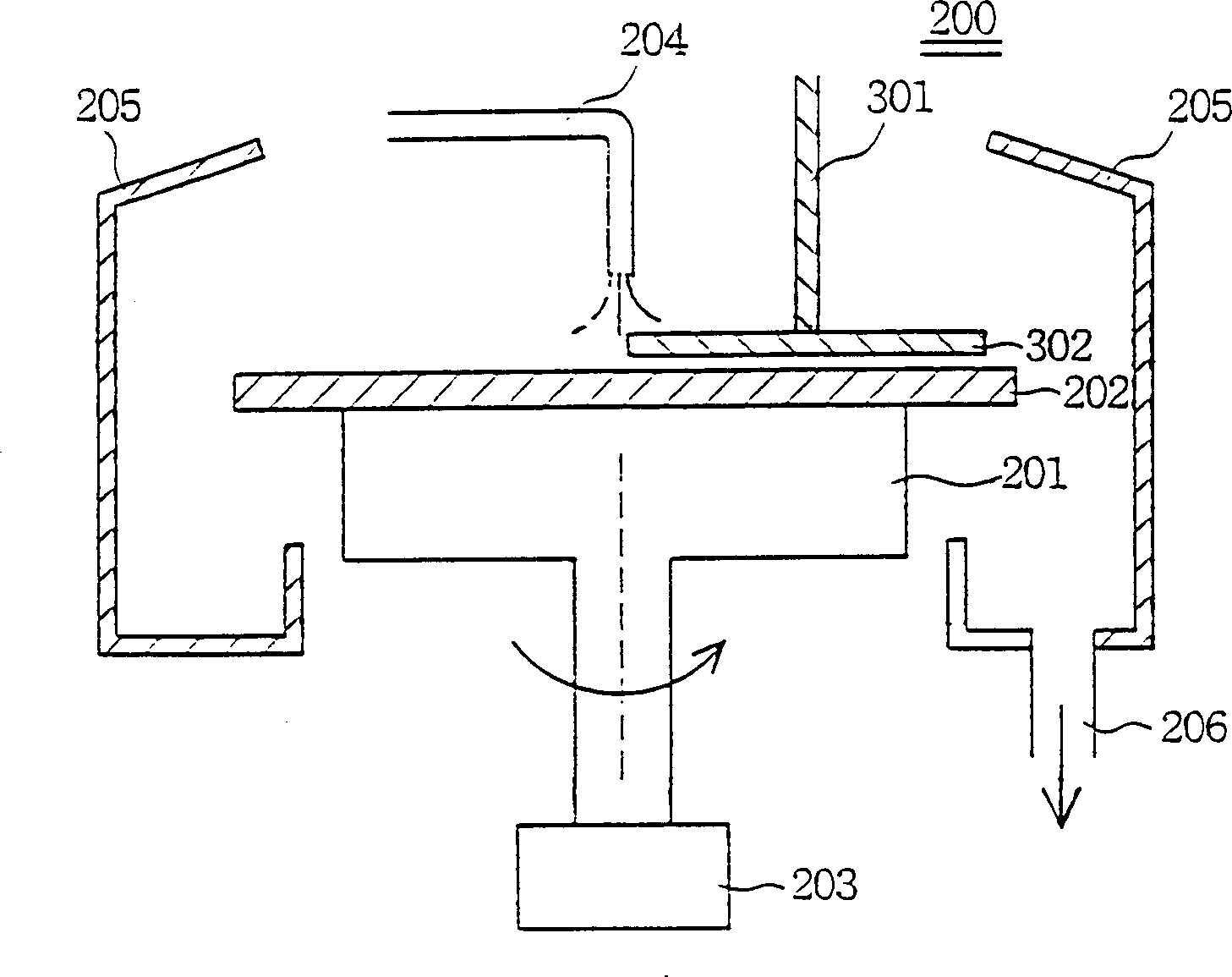

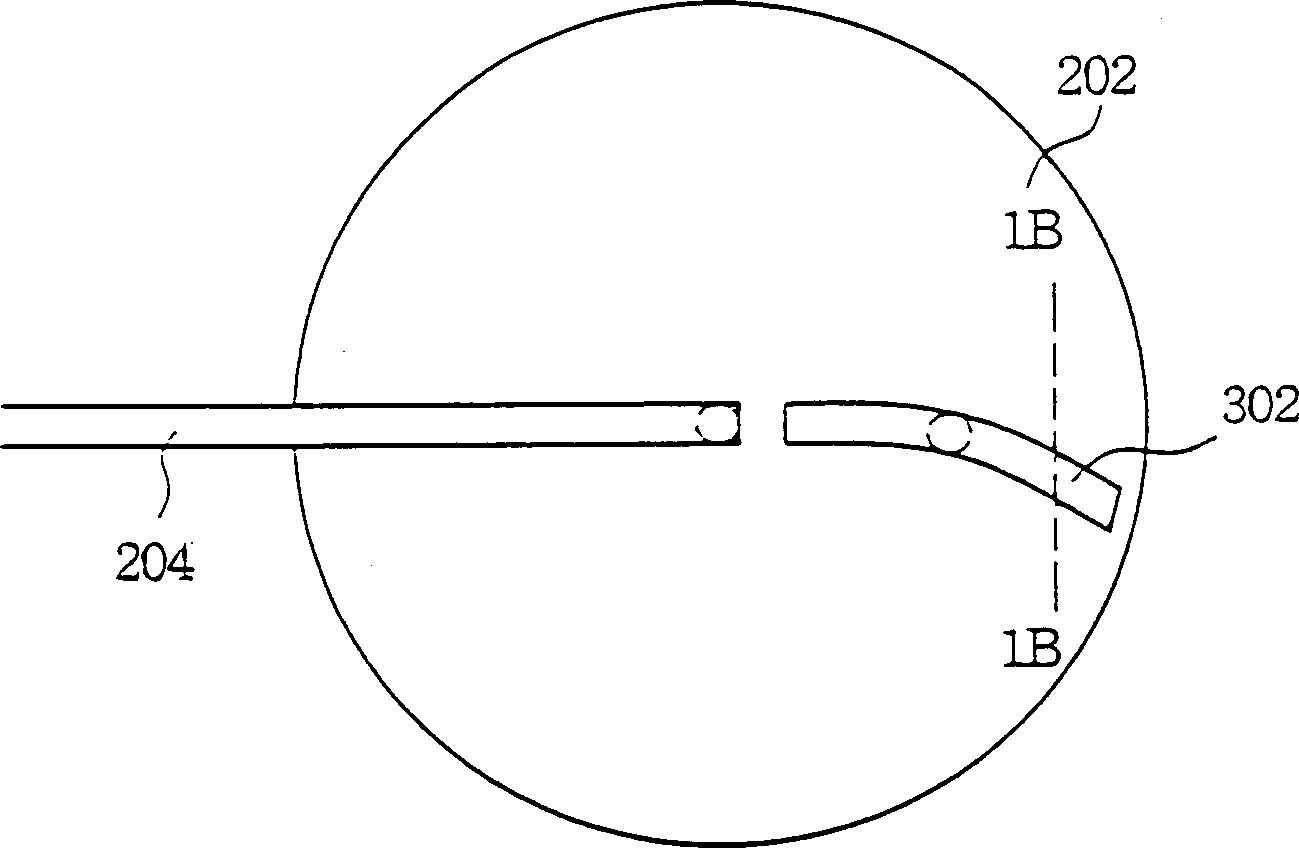

[0026] The wafer cleaning device of the present invention mainly includes two parts. The first part uses the centrifugal force of rotation to remove particles attached to the wafer with chemical cleaning agents. The second part is a curved brushing device. The curved brushing device is used to generate a shear stress to remove the wafer. At the same time, the curved device can block the che...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com