Molten steel scavenger

A purifying agent and molten steel technology, applied in the field of molten steel refining treatment, can solve the problems of poor adsorption of inclusions, inability to deoxidize refining slag, and high oxygen activity of molten steel, and achieve the effects of stable application effect, low total cost and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] According to the scope of the chemical composition of the present invention, three batches of molten steel clarifiers were prepared.

[0018] First of all, the batching is carried out, and the CaO raw material can be lime containing CaO>90%, Al 2 o 3 Raw material can use Al 2 o 3 >70% bauxite, Al, Ca, Si, Ba can use metal Al, Ca-Si, SiFe, BaFe, SiCaBa accordingly; the above-mentioned prepared raw materials are broken into particles below 10mm, mixed evenly, and directly added In the electroslag furnace, electrification is used for smelting, and the smelted slag is cooled and crushed into a suitable particle size, which becomes the molten steel purifying agent of the present invention. The chemical composition (Wt%) of three batches of molten steel cleaning agents is as described in Table 1, and the electrified slag temperature of the mixture in the electroslag furnace is as shown in Table 2.

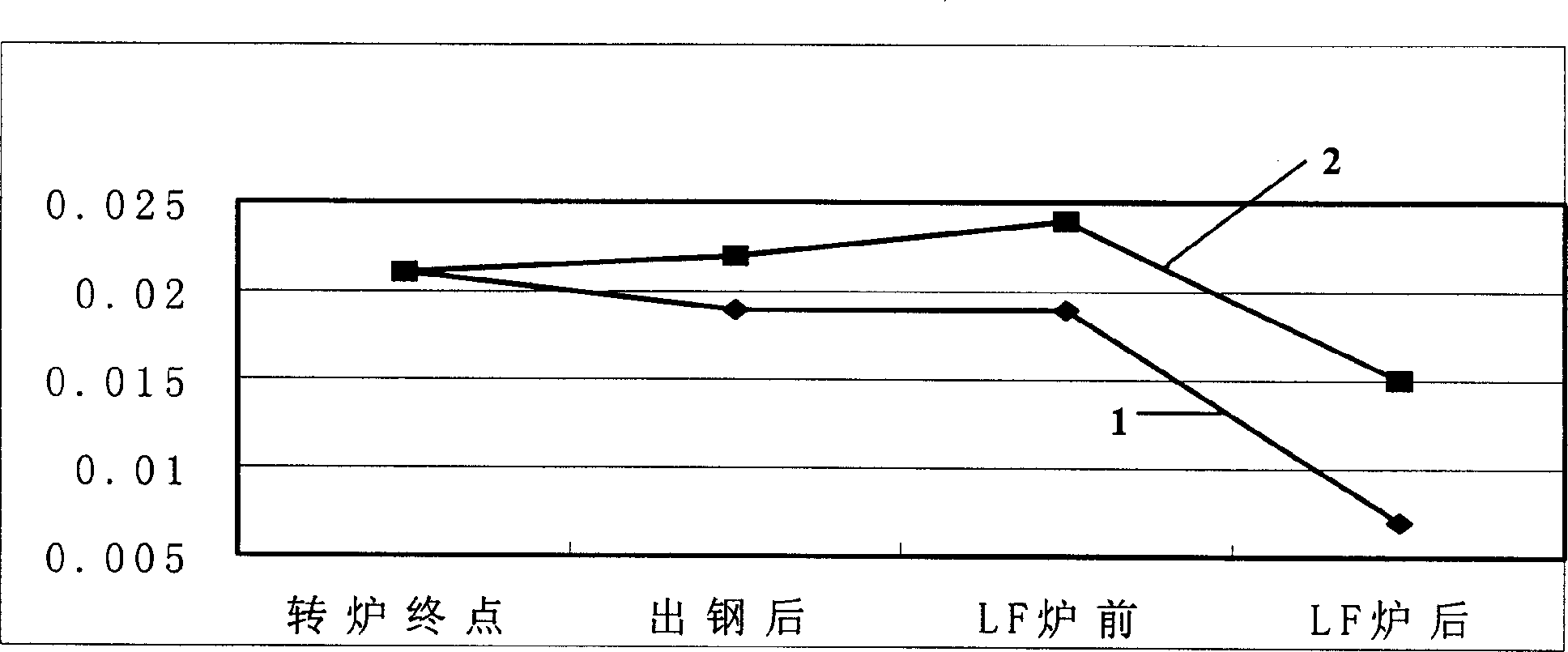

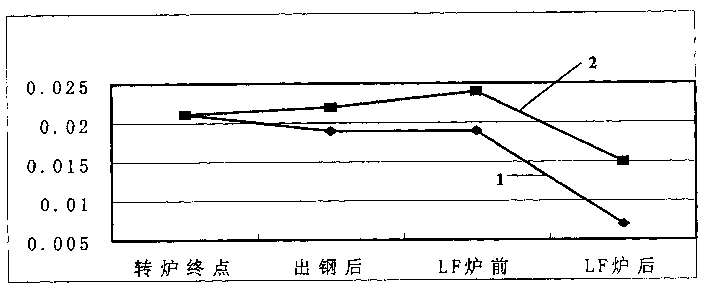

[0019] Using the molten steel purifying agent of batch number 1 in the em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com