Water penetrating pipe with strip projected parts and connection methods

A connection method and permeable pipe technology, applied in the field of permeable pipes, can solve the problems of small drainage space, reduced bending resistance, and small drainage capacity of drainage grooves, and achieve high drainage capacity, enhanced longitudinal bending resistance, and increased The effect of seepage pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

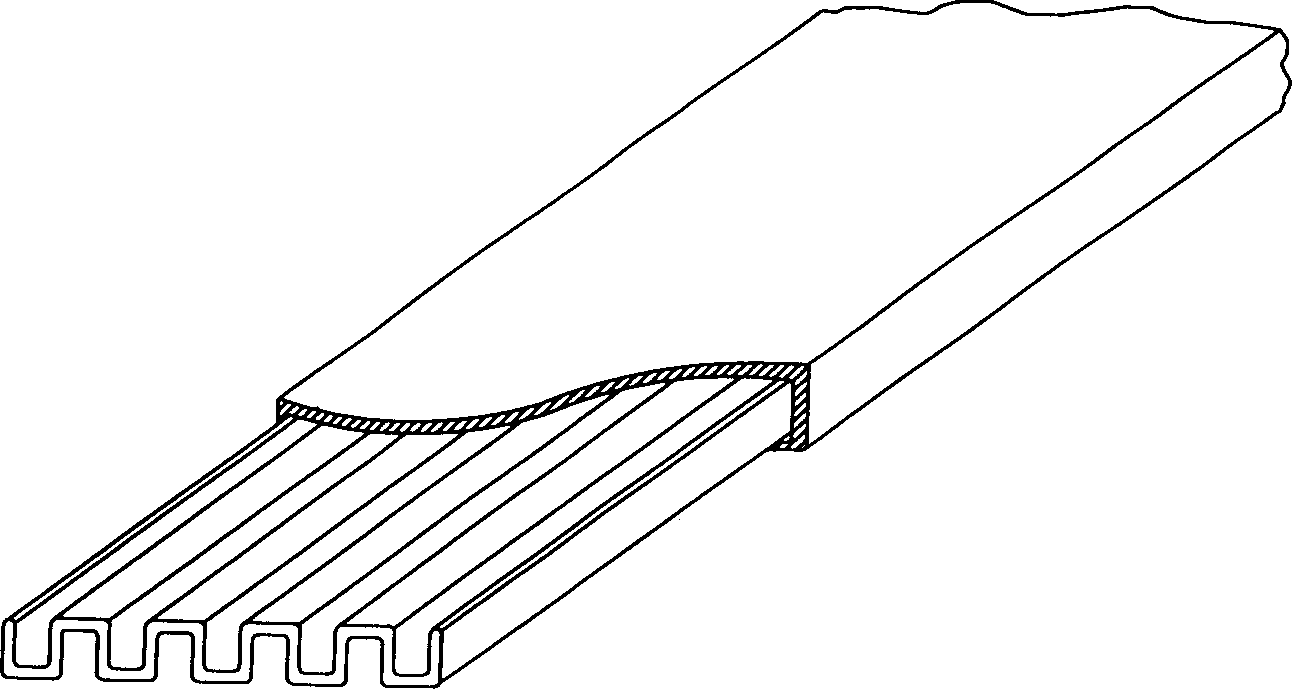

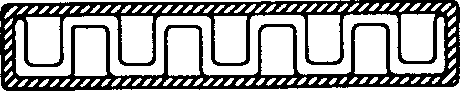

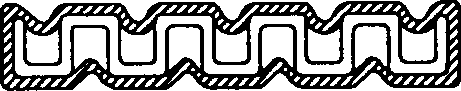

[0035] Such as image 3 , Figure 3-1 As shown, the present embodiment one includes a geotextile layer 5, a water permeable pipe 1 with a water permeable hole 2, and raised strips 3 perpendicularly intersecting the ring direction of the water permeable pipe. Drain grooves 4 are formed between the raised strips 3 . The permeable pipe 1 and the protruding strip 3 of this embodiment are both made of plastic PVC, the protruding strip 3 is welded on the outer wall of the permeable pipe 1 , and the geotextile 5 is bonded to the top surface of the protruding strip 3 . Only one layer of geotextile can be wrapped outside the strip-shaped protruding permeable pipe; multi-layer geotextile can also be wrapped according to needs, and the joints of adjacent layers of geotextiles are staggered; Under the premise that part of the area of the permeable pipe is permeable, a layer of geomembrane is installed on the remaining area. The above PVC permeable pipe 1 is extruded by an extruder, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com