Method and apparatus for absorbing matrix

A substrate and equipment technology, which is used in metal processing equipment, workpiece clamping devices, semiconductor/solid-state device manufacturing, etc., can solve the problems of long holding time, large residual holding force, and difficult separation of substrates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

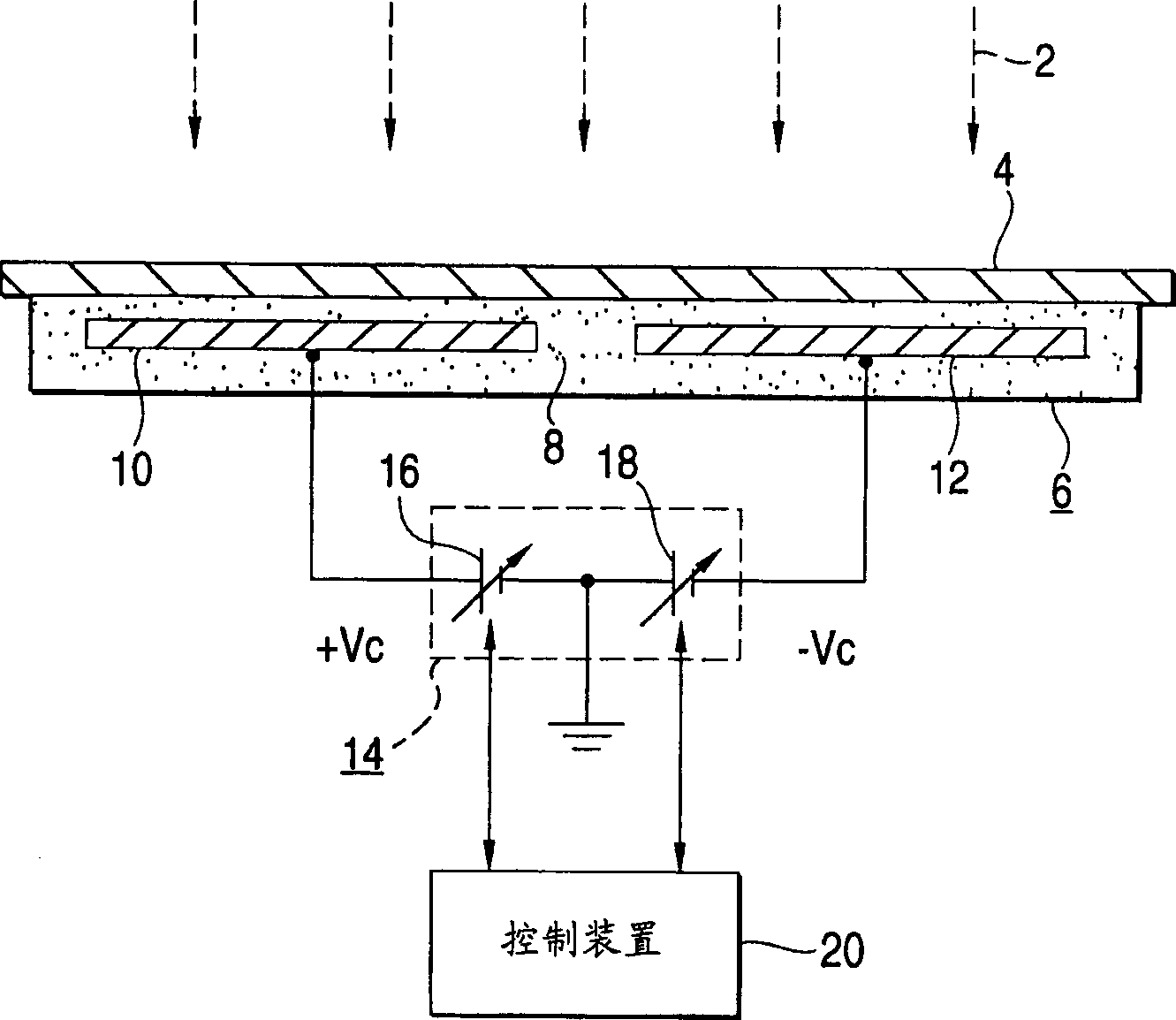

[0030] attached figure 1 is a schematic diagram showing a substrate holding device for performing the substrate holding method of the present invention. In this figure, with the prior art description (cf. Figure 4 Description) the same or equivalent parts are denoted by the same reference numerals. The following description will focus on the differences between this embodiment and the related existing equipment.

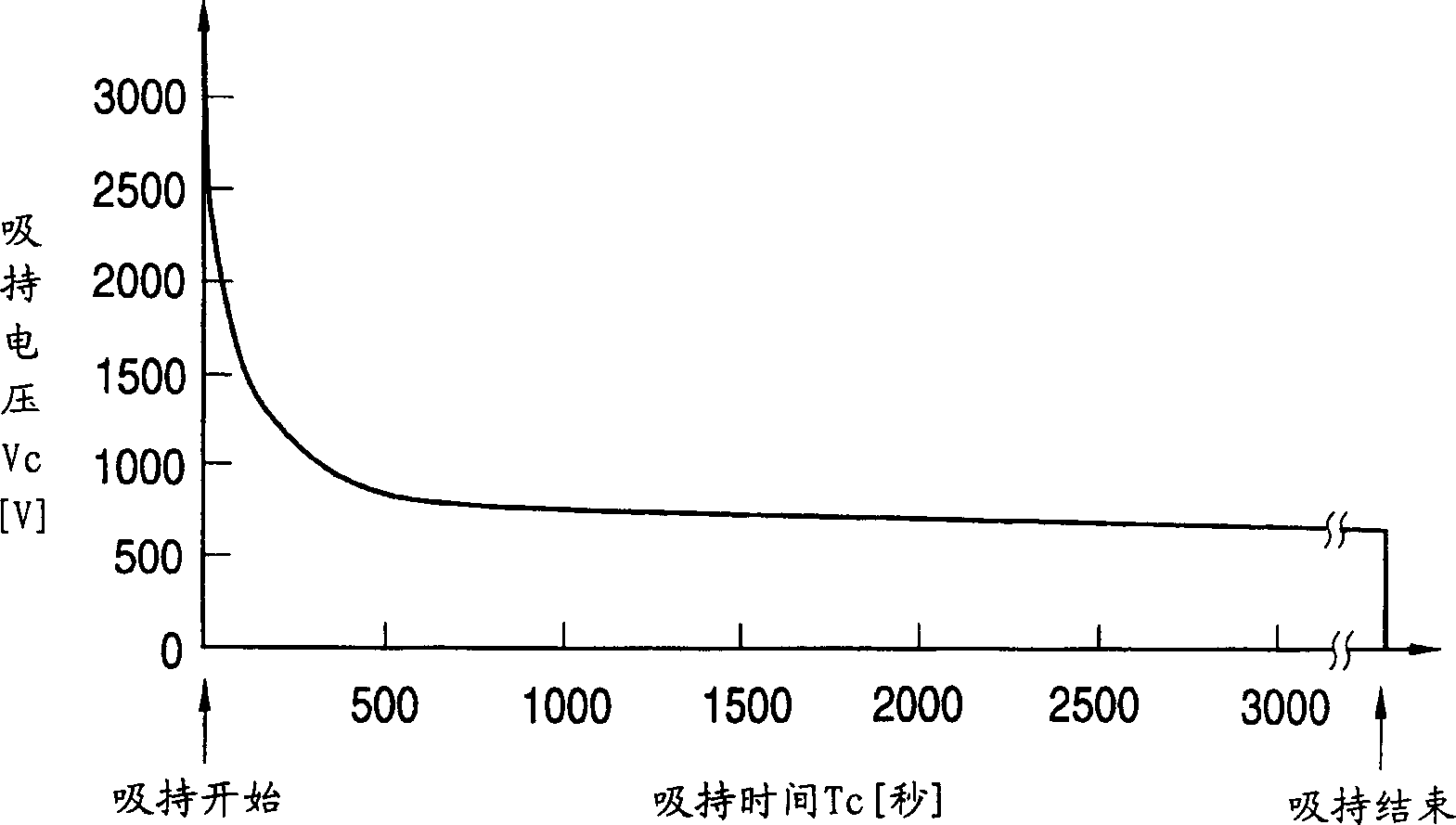

[0031] as in the attached figure 2 As in the case shown in , in this substrate holding device, after the electrostatic chuck 6 starts to hold a substrate 4, the magnitude of the holding voltage Vc is relative to the holding time Tc (that is to say, as the holding time Tc The lapse of holding time Tc) decreases smoothly exponentially. In this specification, the term "starting chucking of the substrate 4" refers to a point of time at which the substrate 4 is placed on the electrostatic chuck 6 and application of the chucking voltage Vc to the electrostatic chuck ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com