Cyclic element of rolling bearing

A technology of ring elements and rolling bearings, which is applied in the direction of bearing elements, rolling contact bearings, rotating bearings, etc., and can solve problems such as high noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

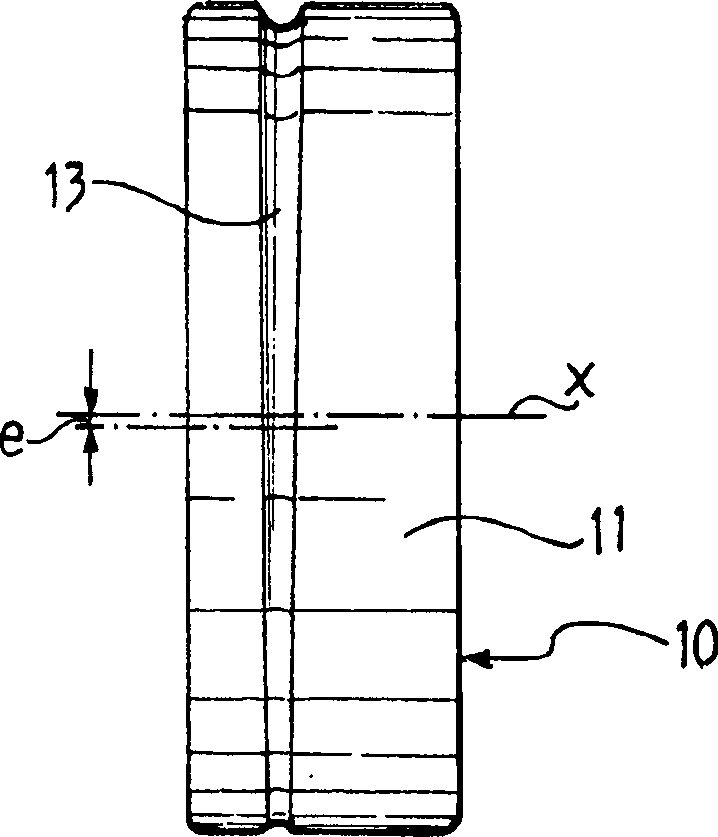

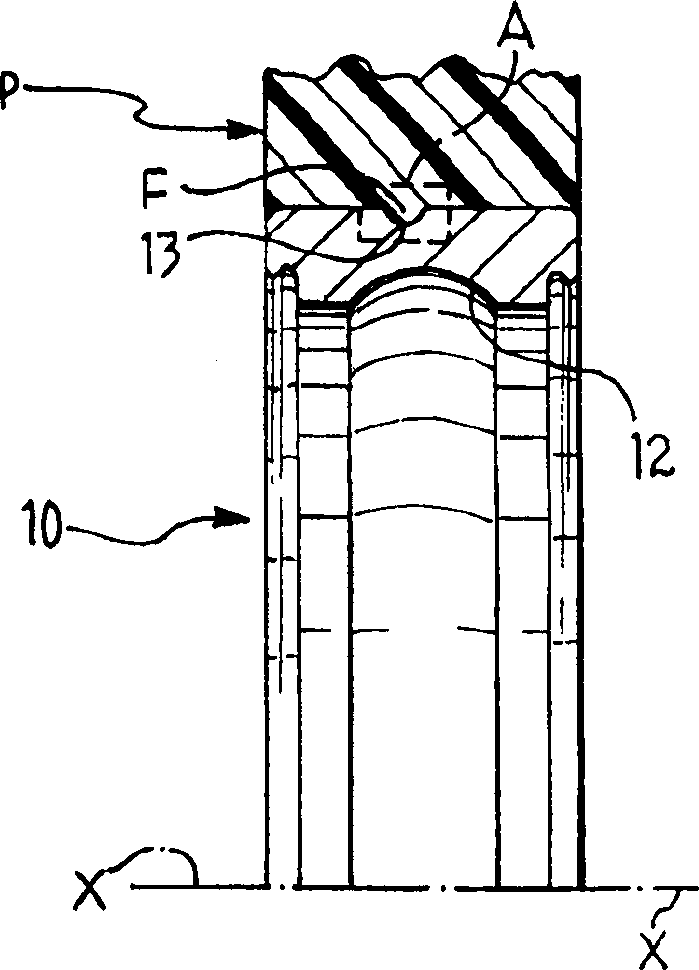

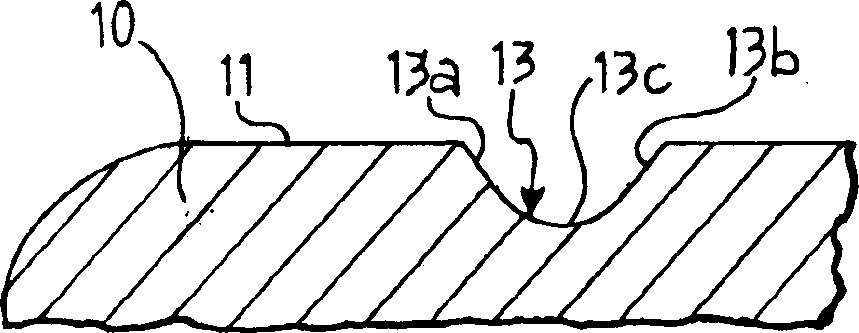

[0015] first reference figure 1 , the annular element constituting a radially outer ring of a rolling bearing is denoted as 10 . The ring element 10 has an outer cylindrical surface 11 and a raceway 12 on its inner surface.

[0016] In this description and claims, terms and expressions indicating position and orientation (eg “radial”, “axial”, “inner”, “outer”) are intended to be relative to the central axis x of the ring element 10 .

[0017] Such as figure 2 with 6 As shown, a body P of plastics material is molded on the outer cylindrical surface 11 and constitutes a fixed housing supporting the support. The body P of plastics material may be a supporting element installed in the washing machine so as to rotatably support via the bearing a rotating shaft on which the drum of the washing machine is fixed. In general, reference to this possible field of application should not be construed as limiting the scope of the invention in any way. For example, the ring element 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com